Proper storage of ENP modules will prevent costly damage

Open shoe press (ENP) modules must be overhauled periodically while the spare module is in operation. Some mills perform the overhaul work in their shop while others send the module to the OEM for repair and rebuilding. Care must be taken while modules are out of the machine to prevent damage from corrosion to the polished and machined carbon steel surfaces.

The instructions below apply to open extended nip press modules which have been shipped to an OEM for repairs and returned to the mill.

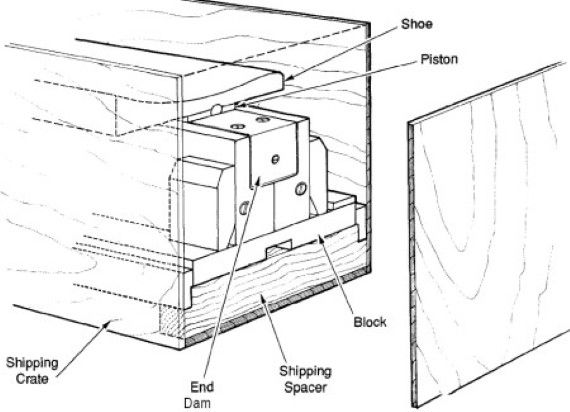

When the module arrives at the mill, inspect it to be sure that the shipping crate is intact and that there is no damage to the shoe assembly caused by the transit. In the event of damage, notify the shippers and OEM immediately.

Storage

If the shoe assembly is not installed in the machine soon after it arrives, store it under cover, in a well ventilated dry area, where it will not be subjected to temperatures below 40°F (4°C).

If storage is for more than one month, it is advised that the shoe assembly be removed from the shipping crate and inspected. The coverage of the rust inhibiting coating must be complete with no exposed spots where rust can form. If exposed areas are found, follow procedures outlined in the next section to repair the coating. If and when the assembly is completely protected, place it back into the shipping crate and cover the crate with a waterproof canvas or tarp.

Repair of open areas in protective covering

If there are any open areas in the protective coating on any surface, they must be cleaned before the coating can be reapplied. Clean and polish these areas as follows:

- Wipe the affected area with clean rags.

- Apply rust inhibitor using soft brushes (i.e. a general purpose rust preventive for long-term protection of metal surfaces exposed to outdoor storage conditions). Recommended thickness is 2.8 mils.

- Polish the shoe surface areas showing corrosion with a crocus cloth. If this fails, a coarser material such as 400 grit emery paper should be used. These areas must then have a final polishing with a crocus cloth.

- All other areas of the assembly requiring repair should have the corrosion removed with 400 grit emery paper.

- If the surface is to be held open for inspection for more than a day, cover the uncoated surface with grease.

- After inspection, remove the grease with industrial alcohol, and apply rust inhibiting coating.

Preparing the shoe module for installation

- Obtain and set-up equipment required, based on the shoe installation/removal instructions for this machine.

- Removal of the protective coating is accomplished by rinsing in petroleum solvent or vapor degreasing.

- Review the assembly procedures for the ENP shoe assembly module as outlined on the Beloit assembly print for the specific machine.

- Make sure all bolts are torqued to the proper specifications and all piping connections are tight.

Suppliers

Some suppliers of rust-inhibiting coating and coatings (in bold) supplied:

Ashland Chemical Co.,

Tectyl #506 WD

Milwaukee, WI

Rock Valley Oil & Chemical Co.,

Nox-Rust X-110

(Daubert Chemical Co.)

P. 0. Box 293 Rockford, IL

For more information on storage and maintaining your shoe press in optimum working order, contact your Valmet representative. Paper Machine Maintenance School covers shoe presses in detail.