The world needs sugar. Sugar is more than a sweet delight for households; it’s also used in various industrial applications. Global sugar consumption is around 180 million tons per year. That’s a lot of sweet stuff to be produced. Did you know that valves are extensively used in the production process? Read on to learn more about the sweet flow.

It may be difficult to imagine that sugar has been used to add sweetness to our food and drinks for almost 2,000 years. Today, the world’s biggest sugar producer is Brazil, followed by India, the EU, China, and the United States.

Sugar is used in a variety of products: from candies and bakery goods to juices, soft drinks, marmalades, and fast food. The sweet stuff is also required for canned products, such as pickles, mustard, ketchup, dressings, and other condiments. Sugar is also a necessity in the pharmaceutical industry. Sugar cane is also used to make alcoholic drinks, like rum and liqueur – and even champagne. One interesting fact is that Brazil, the world’s second biggest ethanol producer after the US, makes most of its ethanol fuel from sugar cane. A beneficial by-product of beet sugar production is animal feed. So, sugar fuels the world in many ways.

The sugar industry faces challenges, but also opportunities

The Covid-19 pandemic had a dramatic impact on sugar demand, but sugar consumption has been on a downward trend over the past 20 years in the US and many European countries. The main reason for this is the increasingly health-conscious mindset of consumers.

One key challenge for the sugar industry is the low price of sugar; in fact, the price is lower than the cost of production for many producers. Covid-19 has had some impact on this, but the main reason for the low price is the sugar subsidies that have driven market costs below a sufficient price.

Another challenge involves increasing production rates while reducing freshwater consumption. As sugar prices decrease, production plants need to produce more sugar to cover the costs and to be profitable – while keeping sustainability and environmental regulations in mind.

The sugar industry has opportunities that can be explored, such as fully utilizing the side streams and other parts of the raw material. Bioproducts are now being explored as supplementary products for sugar processing plants. This is an area that requires continuous research and further development. Valmet has experience in many bioproduct applications. We understand that the raw materials must be utilized more efficiently, and we know that this requires using the right flow control products in the right applications.

Sugar production process – where are valves needed?

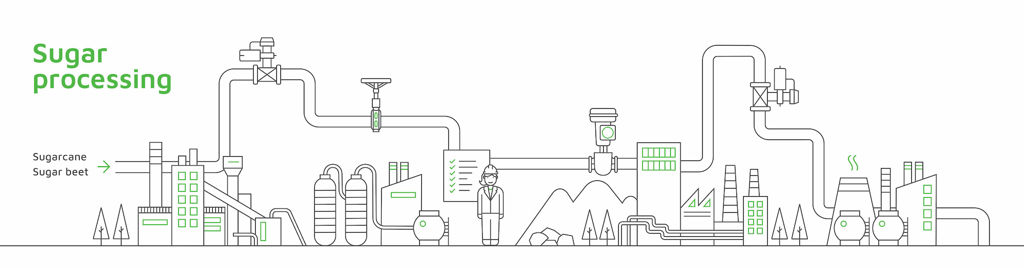

Producing raw sugar involves a variety of steps. After harvesting, washing, and cutting, the main process starts with juice extraction. At this stage, the raw materials – sugarcane or sugar beets – are milled; then the sugar is extracted to produce a sugar-rich juice. The juice is purified, filtered, and clarified to remove the suspended solids. The clarified juice is then boiled, which is followed by crystallization. At this stage, a single-stage vacuum pan is used to evaporate the syrup until it is saturated with sugar crystals. The next step in the sugar production process is centrifugation to extract the crystals from the liquid. The dried crystals are then separated into various sizes and finally packaged and delivered to the customer.

Sugar production involves many fluid streams that require controlling and isolating – and this means the process requires valves. We provide high-performance valve and automation products for every stage of the sugar production process.

Our solutions for the sugar industry

What kind of valves are the most suitable for the sugar industry? The ‘sugar’ valves must withstand continuous operation and may even need to handle erosive slurries. Dependability and low maintenance costs are key drivers for the sugar industry. This requires valves with high reliability and efficiency and, ultimately, high uptime and a very long service life.

This requires valves with high reliability and efficiency and, ultimately, high uptime and a very long service life.

Sugar processing conditions can be tough, requiring robustness, accuracy, and reliability of the valves. One of the best solutions is the Jamesbury™ Wafer-Sphere™ high-performance butterfly valves; they are well-suited and cost effective for many of the sugar process applications, such as steam, juice, and evaporators. For demanding slurry applications, we recommend the Neles™ E-series ceramic ball control valve. It’s designed to meet the most severe erosive service requirements and is successfully used in the liming operation. When it comes to control valves, accuracy and rangeability can maximize production. The Neles™ R-series V-port segment valve is the clear choice for process control throughout the plant. For the smaller steam and process lines, Neles Linear globe valves can be the best choice. Finally, what goes on top of the valve can be just as important. We offer best-in-class actuation and controller products. The Neles NDX™ valve controller can withstand challenging conditions; it provides accurate control, it works with any control valve, and it’s safe and easy to operate. The Stonel™ Axiom AN on/off valve controller offers a unique and cost-effective integrated approach to discrete valve control.

These are just some examples of our valves and valve controllers suitable for sugar processing. You can learn more by visiting our page about valves for the sugar industry or by contacting our experts. We are always happy to help.

So, how can Valmet's flow control business help sugar producers improve their process? By offering valves that provide continuous, dependable performance for high productivity and high uptime, while factoring in safety and sustainability. This ultimately leads to more reliable, more profitable sugar production.

Sources:

Global sugar market report 2020/21, Ragus (www.ragus.co.uk/global-sugar-market-report-2020-21/)

World Sugar Outlook in 2020-2021, Sugar Asia Magazine (www.sugar-asia.com/looking-ahead-to-world-sugar-outlook-in-2020-2022/)

Leading sugar producers worldwide 2020/2021, Statista (www.statista.com/statistics/495973/sugar-production-worldwide/)

The Sugar Association (www.sugar.org/diet/intake/)

How Sugar Is Processed, Food Technology magazine article, July 1, 2020 (www.ift.org/news-and-publications/food-technology-magazine/issues/2020/july/columns/processing-how-sugar-is-processed)

The text has been updated in April 2022, due to the company name change to Valmet.