Common fluids valves explained: Pressure reducing valve

Below is a sandwich style pressure reducing valve; it is used to create and hold a downstream pressure setpoint. The valve is typically an open, two-way valve that lets oil flow through it until a specific pressure is reached downstream, whereupon it mechanically moves to throttle the flow into the downstream branch. Other larger types of pressure reducing valves that attach to a subplate are also used to control downstream pressure. Sandwich style pressure reducing valves are very common on Valmet equipment as they are easy to fit in a stacked hydraulic valve block circuit.

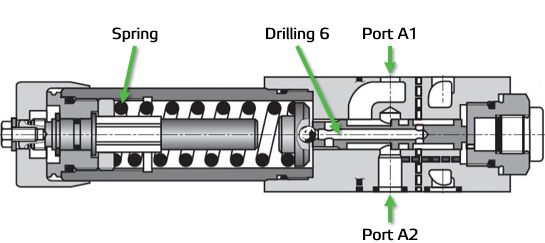

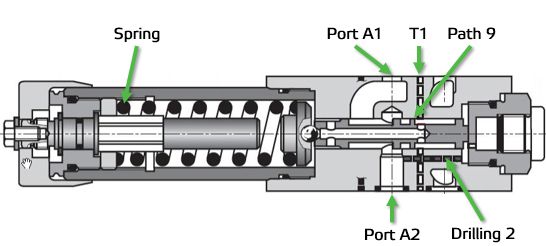

As with pressure relief valves covered in a previous article, pressure reducing valves incorporate springs in them to set the target pressure. Below are illustrations (courtesy of Rexroth) that show how such a valve works. In this case, we are examining a ZDR 6 DA1-4X YM valve.

Operation

Stage 1

Stage 1: no spring pressure, oil flows from A1 to A2

With no spring pressure asserted by spring #3, ingoing port A1 flows through to port A2 unrestricted. Oil in the spring cavity is always vented to the tank port via drilling #6. This guarantees that that only the spring is used to create back pressure that controls the pressure in A2.

NOTE: When installing new pressure reducing valves, it is a good idea to back off the spring before starting the system back up to prevent over pressurizing the system. Then, when the oil supply is going to the valve, slowly increase the valve setting until the target pressure is reached.

Stage 2

Stage 2: Spring pressure, flow from A1 to A2 is blocked

As pressure in port A2 increases due to back pressure downstream, the pressure in port A2 is also directed to the right side of the spool via drilling #2. This pushes the spool left against the main spring, and closes the flow from port A1 to port A2. This occurs until the pressure in port A2 is balanced with the spring setting. If pressure is higher than the spring setting, the spool moves further toward the spring until part of the spool crosses over into the port A2 and directs some oil to the tank via path #9.

Troubleshooting

One aspect of pressure reducing valves is there is always flow through them. Either flow is moving out of the valve through port A2 or back to the tank via T1.

The pressure drop and flow across pressure reducing valves creates heat. When troubleshooting these valves, measuring ingoing and tank line temperatures are a good indication if the valve is functioning properly. If there is no flow to the cylinder from port A2, the line will normally be cool. A warm A2 port indicates there is flow to the rest of the hydraulic circuit.

For more information on maintaining your hydraulic system, contact your Valmet representative.