Making a big difference to ethylene project engineering

The global ethylene market is booming, with several crackers under planning, engineering or construction, particularly in Asia, the Middle East and the US. This upswing is being driven by the rising demand for ethylene and other olefins for various plastic and chemical applications, as well as abundant gas feedstock availability, specifically in the US and Middle Eastern markets.

Ethylene is a basic building block in the chemical industry and a primary link between chemical companies and petroleum refiners. An ethylene or olefin plant will mostly produce ethylene, but also breaks the feedstock into other usable byproducts, such as propylene, butadiene and gasoline.

As demand for ethylene rises, so does the need for valve solutions that offer maximum reliability, safety and performance. After safety, uptime is a major determinant of whether an ethylene plant can be sustainably profitable in an increasingly competitive global market. A typical ethylene plant investment can be US$1 –3 billion, requiring a considerable spend for automated control and on-off valves across the entire project. The details of what kind of valves to select for a project really matter.

This article will discuss ethylene plant project engineering from an automated valve selection point of view. It also considers which valve options to consider to achieve set reliability targets and keep project costs under control.

The role of steam and feed control

An ethylene steam cracker can accept a variety of feedstocks, including naphtha, ethane, propane, gas oil. The choice of feedstock depends on the cracker furnace construction, the availability of the feed, its current market price and the desired end products.

Dilution steam is injected into the furnace tubes to protect the pipes from fouling or forming coke. Therefore, the hydrocarbon-to-steam ratio should be optimised to achieve optimal flow conditions. The flow rate of the steam depends on the severity of the feed. Steam can also be used for decoking the furnace. Therefore, wide rangeability of the valve controlling the steam may also be required.

The process system in an ethylene cracker must supply the correct amount of raw material to produce the desired end-products. The feedstock supply valve must be able to control this accurately, taking into consideration that in some cases the feedstock can be a liquid and a gas in others. This makes it one of the most important control valves. As the flow rate difference between low flow and full capacity can be significant, some ethylene producers use separate valves for each case.

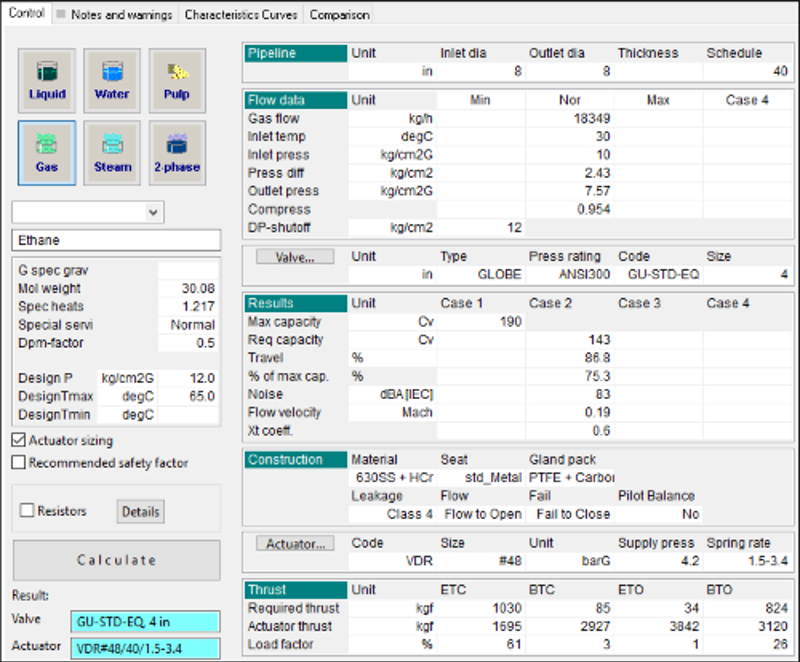

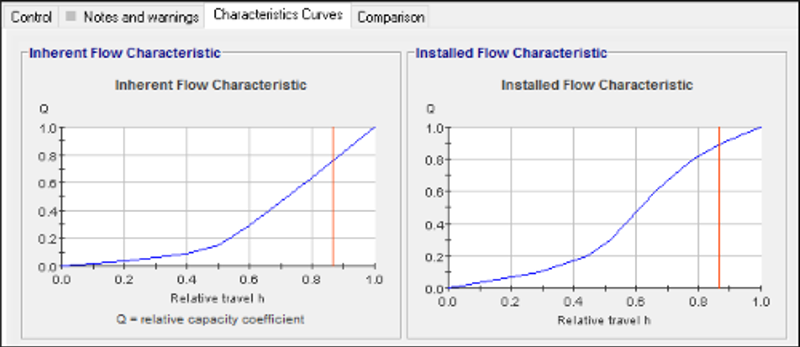

Globe valves have a strong position when it comes to controlling the dilution steam in cracker furnaces. They are a tried-and-tested technology and economical from a project engineering point of view.

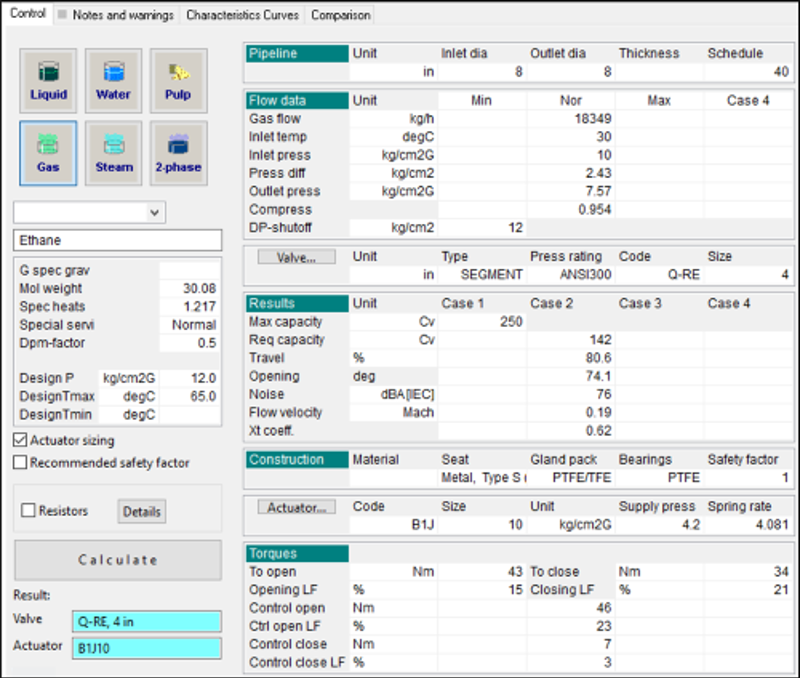

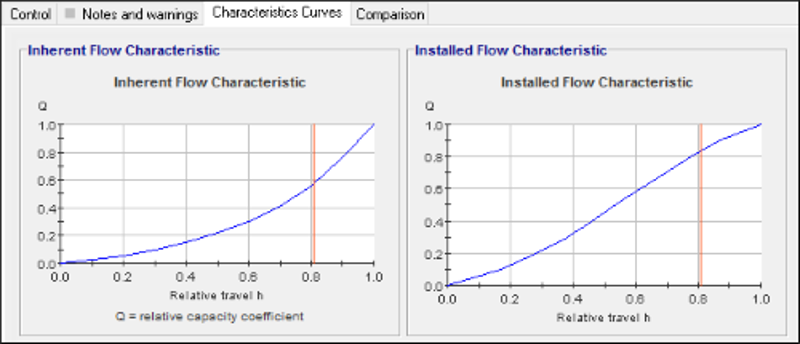

Adding rotary valves to the offering, such as a V-ported segment or eccentric plug, gives more opportunities for reliability and cost optimisation. They are effective choices especially for sizes of 3 in. and larger, and for applications with sticky flow media and particles present, such as coke and heavier hydrocarbon feedstock in crackers.

Another benefit of rotary valves is the reduced cost for piping, cabling and other connections enabled by their wide adaptability, particularly V-ported segment valves. This eliminates the need to use a split range control and a secondary valve in the piping.

Decoking the furnaces

Since the steam cracking reaction occurs under high temperatures (750 – 850°C [1380 – 1560°F]), it leads to the deposition of coke on the furnace tubes. Because this degrades the efficiency of the furnace, regular decoking is required, typically every two to six months per furnace, depending on the type of feed and furnace severity.

A steam cracking plant has several furnaces. While one furnace is undergoing decoking, the others remain in production. Decoking is typically performed by steam or air. When end of run conditions are reached, the hydrocarbon feed is discontinued, the furnace isolated, firing rate in burners adjusted, and controlled amounts of dilution steam and air are admitted to remove coke deposits. Decoking effluent is routed to decoking drums, where the coke fines are separated from the decoking effluent gases.

On-line steam or air decoking will allow the furnace and quench exchanger system to operate through several successive cycles. The transfer line valve (TLV) and decoking valve (DCV) must be able to withstand high piping forces, due to high temperature variations. Downstream processes must be protected from decoking effluent, high temperature steam and coke to ensure plant operability and safety. Therefore, 100% valve tightness is essential.

Gate valves are typically used for the transfer line and decoking. Issues with gate valves are related to their ability to withstand the dirty decoking effluent with coke accumulation, which may cause a valve to get stuck.

Since most decoking valves are 20 in. and larger, the gate valves become heavy items to install. Additionally, they require supporting structures to avoid excessive piping stresses.

An alternative to gate valves are double-block and bleed butterfly valves, which can resist coke accumulation and jamming, overpressure during valve closing and the continuous steam flow that keeps the seating area hot. Stellite parts of the body seat and the seat sealings on the disc ensure that the hard coke particles do not erode the important elements of the valve, keeping the valve 100% tight. The rotary design also eliminates shaft packing wear.

Due to the compact size of these valves compared to gate valves, they are economical and reduce costs associated with lifting, installation and supporting structures. They also better resist pipe vibration. The double-block and bleed feature of the butterfly valve also reduces costs by allowing the use of a single valve instead of two gate valves.

Fuel gas

Proper combustion in cracker furnaces maximises heat transfer and minimises fuel gas consumption and related costs. Variations in fuel gas composition and different operating conditions at startup, during normal operation, decoking and at shutdown means that valves must control various loads, requiring valve rangeability. This is typically solved using a split range configuration with globe valves. Another solution is to use V-ported segment valves with wide rangeability. This enables accurate control of both small and large flows with a single valve solution instead of two globe valves.

Single-source supplier and manufacturing responsibility for all valve components – including the body, actuator and topworks for fuel gas burner system ESD and on-off valves – is the key issue when assessing operational availability of any valve solution. A certified assembly enables an easy startup and reliable shutoff when the furnace capacity needs to be adjusted or a safety action must be performed in challenging process conditions.

The burner system valves are expected to remain fully operational and fulfill approvals after long periods of time. Third-party type approvals, such as EN161/ISO 23553-1, mean that the whole valve, the actuator and other components have gone through rigorous testing, which involves tens of thousands of open-close cycles and frequent seat leakage and fugitive emission controls. For example, a 1 in. valve needs to remain bubble-tight, even after 250 000 cycles.

Type-approved burner emergency shutdown and shutoff valves ensure that there will be no disputes with the authorities during commissioning inspection. Therefore, having approvals completed by the supplier can help save time in plant startup and reduce inspection costs on site.

Compression and drying

In the compression zone, the feed is compressed in multiple stages, mainly because the compressor discharge temperature must be limited to 100°C (210°F) to prevent polymerisation from occurring. Condensates are recovered between each stage as they are formed due to the increase in pressure and the cooling following each compression.

There is a minimum capacity for each compressor at every speed, below which the operation becomes unstable. This instability is accompanied by a characteristic noise known as ‘pumping’ or ‘surge’ and occurs when the pressure at the outlet of the compressor is higher than that produced by the compressor, which causes the flow to momentarily reverse. The resulting violent oscillation of gas pressure can cause severe and costly damage to the compressor in a few seconds.

To avoid this, a bypass valve can be installed between the discharge of the compressor and the inlet. When higher pressure is detected at the outlet, the valve opens fully, in less than a second, to release the pressure to the inlet side. Compressor recycle/anti-surge valve is to recirculate the flow during startup, or when less gas is required.

Suppliers with a wide valve offering provide the ability to cope with all challenges and get the best performance. For high differential pressures, globe valves are the typical choice. For high rangeability, rotary valves may be used because of their high capacity. If the anti-surge is controlled by a split range with two valves, the valve with the lower differential pressure may also be a triple-offset butterfly valve.

After compression, water must be eliminated from the cracked gas before the gas enters the cold zone because entrained water allows ice and gas hydrates to form once the temperature drops below 15°C (60°F), which may cause clogging. Drying is accomplished by utilising molecular sieve beds. These beds must be periodically regenerated with hot gas. Usually, two to three beds are utilised, and switching valves are used to switch these beds between operation and regeneration.

Trunnion or seat-supported ball valves are the typical choice for use in cracker dryers, where the valves face switching every 2 – 6 hrs, temperature swings from ambient to 350°C (630°F), and operating pressures of 20 – 50 bar (29– 725 psi). These valves provide long-lasting seat tightness and particle build-up prevention, with solid-proof seats that also wipe off particles from the ball surface every time the valve is operated. Compared to rising stem ball valves, rotary valves provide a compact, light and multiple piping orientation option, for easy and economical engineering and commissioning.

Cold zone and fractionation

The dried gas enters the cold box, where the temperature of the feed is decreased stepwise to separate different components from the feed. Usually, five stages are involved, and the gas exiting at the top has a minimum temperature of approximately -165°C.

The last stage yields a gas stream of approximately 95% hydrogen, which can be purified further in a pressure swing adsorption (PSA) unit. Other recovered fractions are sent to the cold separation train, which consists of a set of distillation columns. The exact configuration of the columns varies between steam crackers, but it commonly consists of a demethaniser, a de-ethaniser, an ethylene-ethane splitter, a depropaniser, a propane-propylene splitter and a debutaniser.

The majority of the valves in cold zone fractionation can be considered ‘off-the-shelf’ items, where the choice should be made according to size, pressure class and temperature, as usual. Control valves in a refrigeration system require special attention. Enhanced binary refrigerant – a mixture of methane and propylene or propane, in either gas or liquid state – creates the challenges of high pressure drop, where noise and cavitation may be an issue, combined with low temperature from -60 to -150 °C (-70 – -240°F).

The solution for demanding refrigeration high pressure drop valves is to select a balanced plug globe valve with multi-stage trim, for pressure reduction that eliminates noise and cavitation effectively. The valve must be suitable for cold temperatures.

Conclusions

Partnering with valve suppliers who offer single-source responsibility for the whole valve package pays back over time. An investment in tried-and-tested valve solutions, proven in use by ethylene license technologies and approved and certified by third-parties, can make a real difference in securing agile ethylene project execution throughout all project phases, as well as safe and profitable commercial operation.

It is, therefore, important to choose a supplier with a wide valve offering and extensive knowledge in ethylene project valve selection. The supplier should also be capable of offering a variety of solutions that utilise the full benefits of combining sliding steam and rotary control valves. This keeps project engineering costs under control and ensures that the plant can be commissioned, started and operated reliably.

Text by Heikki Voutilainen. For additional info, please contat lindsay.coutinho@valmet.com

Article "Making a difference" originally published in Hydrocarbon Engineering magazine, September/October 2018 edition.

Text originally published in 2018, and slightly updated in April 2022, due to the company name change to Valmet.

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

Subscribe