Scrubbing to cleaner seas

Although the question of scrubbers has been at the forefront of the marine industry for a number of years, it seems that shipowners and shipyards are only now waking up to the fact that they are in a hurry to act before 2020 when the new SOx regulations come into effect. Everyone has been waiting – holding back – while the debate has been raging: scrubbers or no scrubbers at all?

Although the question of scrubbers has been at the forefront of the marine industry for a number of years, it seems that shipowners and shipyards are only now waking up to the fact that they are in a hurry to act before 2020 when the new SOx regulations come into effect. Everyone has been waiting – holding back – while the debate has been raging: scrubbers or no scrubbers at all?

Just a year ago, there was a flurry of new scrubber orders when one or two scrubbers were part of the marine industry recommendations. Today, scrubbers have become mandatory. The IMO set the global limit of sulphur in marine fuels at 0.5% in October 2016. Now the Exhaust Gas Scrubbers Association is urging ship operators and refiners to put plans into action, since the deadline to comply in 2020 is approaching quickly.

From land-based power plants to marine

Since 2006, Valmet has focused on developing its scrubber technology for marine. Earlier, the company had well-proven references for these systems from land-based power plants. But now that the marine industry is facing the introduction of more stringent SOx regulations, Valmet’s reliable scrubber systems have demonstrated that they are ideal for use on vessels too.

Cruise ships have been the first movers. They have been the ones to embrace green washing and have adopted scrubbing technology to comply with the pending regulations.

The arrangement of scrubber systems in cruise vessels in general is more complex than with other types of ships. Cruise vessels typically also have several scrubbers installed. Therefore, orders for scrubbers in the European cruise industry are booming. But recently, cargo ships, too, started to wake up to the advantages of implementing scrubber systems for newbuilds and retrofits.

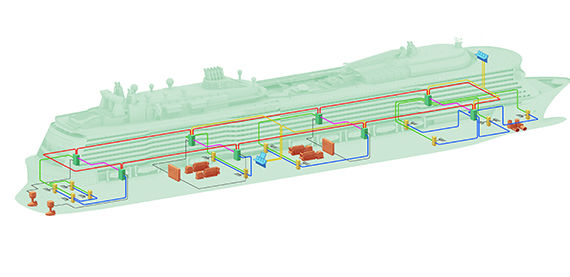

Caption: Valmet SOx scrubber

Listening and tailoring to needs

The key for Valmet in making an entry into the cruise vessel sector with its scrubber technology has been listening to customers and tailoring a complete scrubber system to fit the extremely limited space available on board cruise ships and now also cargo vessels.

“One of our advantages is the ability to offer a very highly customized scrubber solution,” says Teemu Toivonen, Product Sales Manager from Valmet. “Every vessel is different. Therefore, every scrubber system should be designed with ship-specific conditions in mind.”

“We successfully entered into the marine industry primarily because we were open to listening to the needs of the shipowners and shipyards,” he continues. “We physically tailor and modify the entire scrubber system to match their limited space needs. Our customers have really appreciated the fact that we have changed the system specifically to fit their vessel layout. This is one of our main strengths.”

“We’re also quite flexible in terms of scope. Our initial scrubber systems were small, but we’ve steadily been moving into larger-scale deliveries. In fact, we’ve received several repeat orders for larger-scope systems that we’re turning around for our customer with a very fast response time,” Teemu states proudly.

Complete scrubber system

Another one of Valmet’s advantages is the ability for a full-scope delivery, including the entire scrubbing system, complete with water treatment and automation.

“The water treatment system is based on our own strong competence area, which has been used and proven in other industries, such as pulp, paper and power,” says Niko Heinonen, Product Sales Manager, Valmet. “For marine, our membrane filtration technology leads to exceptionally low operational costs.”

Today, Valmet offers two basic types of exhaust gas scrubbers: an open loop scrubber that uses seawater and a closed loop system that uses alkali additive. Valmet was the first supplier to offer a hybrid solution to the market. “Hybrid” means that the scrubber system is able to operate alternatively in both open and closed loop modes. This new-generation scrubber allows a vessel to switch easily between the open and closed loop operational modes, depending on location for example, to comply with regional regulations.

Valmet offers customers the choice of different additive chemicals, such as sodium hydroxide (NaOH), for closed loop sulphur emission reduction. “We’ve had decades of experience with numerous reagents. Again, we encourage our customers to choose the solution that works best for their own requirements,” Niko emphasizes.

“We also offer the option of using seawater as the scrubbing water in a closed loop. This actually originated from a specific customer request. And as a response, we went on to design the system based on using seawater,” he underlines.

When combined with Valmet’s automation, the whole scrubbing system and all emissions can be easily and continuously monitored. All key values and trends are saved, and collected information can be used to further decrease operational costs. This is all part of the Valmet DNA automation system, which is the company’s integrated information management system that plays a key role in assuring safe and reliable operations on board vessels. The role of the automation system is to control thousands of signals from locations throughout the ship without the need for operator intervention.

Overall, Valmet’s complete scrubber system is simple and requires low maintenance. The patented new technology and unique features provide more sustainable shipping operations.

One-source supply

Reliability with previous marine deliveries is extremely important for shipowners and shipyards alike. Valmet already has nearly 10 years of experience in marine scrubber systems and over 40 years of presence with automation deliveries to marine, making the company a serious contender in the marine industry.

“We have proven with numerous scrubbing system deliveries that we can achieve what is needed,” says Teemu. “For customers, we are a one-source supplier of the complete package. They can count on getting the ideal solution for their exact vessel specifications. It’s a well-proven package with a high amount of capabilities in our own hands.”

Valmet as a big company also offers customers the assurance of global presence for after-sales service and technical support offices. Especially for marine customers, these service centers are located in places, such as China and Indonesia, that are close to major cargo and other marine routes.

Top-class references

“Although we now have several top references on cruise, cargo and container ships, our scrubber systems are gaining the attention of many other types of vessels, too,” says Niko.

“For example, one of our most recent orders came from the Germany-based TUI Cruises for which we will be delivering the exhaust gas scrubber systems for their new cruise vessels, Mein Schiff 1 and Mein Schiff 2. These ships are being built by Meyer Turku through 2019,” he comments.

For more information:

Teemu Toivonen

teemu.toivonen at valmet.com