Advanced vision and analysis for web quality control

Valmet IQ Web Inspection solution

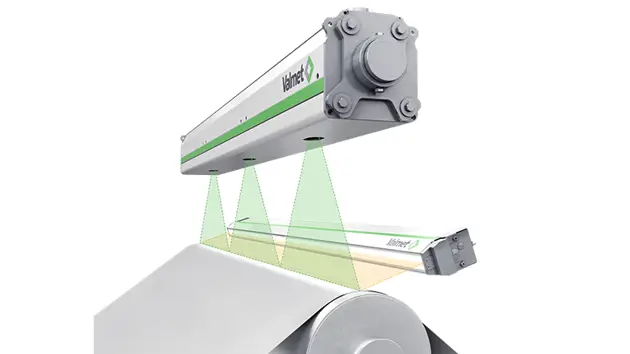

Improve web quality and optimize production efficiency with the Valmet IQ Web Inspection solution. The advanced lighting technology and image processing enable precision detection of production critical defects like never before.

Automatically identify and classify nearly any defect with advanced imaging and analysis

Improve product quality with quick defect detection and pro-active quality management

Improve profitability by increasing line speeds and reduce quality claims

Catch defects before they become problems

Precise web defect detection, identification and classification play crucial roles in web quality control. Accurate and reliable defect detection is simple with Valmet IQ web inspection solutions. Utilizing advanced lighting, ultra-fast cameras and industry-leading software technologies, the Valmet IQ web inspection solution can immediately identify defect, even at high web speeds.

Combined with state-of-the-art image processing and defect classification, you get automatic defect detection and classification with fine-tuned control. Identify off-spec product before it reaches the customer.

With Valmet IQ web inspection solutions, enable to improve web quality and process runnability, as well as optimize production efficiency. You can also leverage integration to Valmet Web Monitoring System to quickly find the origins of quality problems.

Focus on the right factors

With the Valmet web quality control systems, operators can really focus on the specific quality problems that can lead to customer complaints and profit loss. A real-time defect map, automatic defect classification, plus extensive analysis and reports give operators deep insight into the quality of the end product.

Using this wealth of information, operators can make the necessary changes in the machine operations should the data indicate the quality is off. The result is a fiber-based product that meets the highest standards for visual quality, printing performance and high efficiency converting.

Manage quality proactively

The Valmet IQ web inspection solutions do more than deliver amazingly accurate web quality data. You can use the system to proactively manage quality. For instance, for re-reelers and winders there is an automatic target stop control to allow defect patching and enable optimized converting efficiency.

Defects can be checked, removed and reported with winder length syncing that is accurate down to the meter. Customer roll planning, reporting and trim planning tools help you maximize the quality of each customer roll.

Structured and intuitive information

Valmet IQ Web Inspection System is fully compatible with the new Valmet DNA User Interface. The modern and intuitive user interface guides the operators to focus on situation-critical information and make the right decisions instantly. Valmet DNA UI also provides superior user experience.

The integrated quality data combined with the applications maximize the production capacity and improve machine control.