The new standard in premium quality tissue making

Advantage NTT Technology

The Advantage™ NTT® concept is designed for maximum flexibility and can easily swing between energy efficient production of conventional tissue and high quality textured tissue in a few hours.

FLEXIBILITY

Unlimited possibilities for product variations

Fast change from plain to textured tissue

QUALITY

Premium paper quality

Low basis weight and high bulk

SAVINGS

Significant savings in energy and fiber

High capacity and efficiency

Designed for maximum flexibility

The Advantage NTT technology is easy to operate, has high machine efficiency and operates at high speed. The operating cost is comparable to the Advantage DCT technology for textured tissue and less in conventional mode. It is particularly suited for production of premium quality bath, towel, facial and napkin grades from virgin or recycled pulp.

The energy consumption in textured mode is significantly lower compared to the TAD process while in plain mode it is comparable or lower than other conventional tissue making processes.

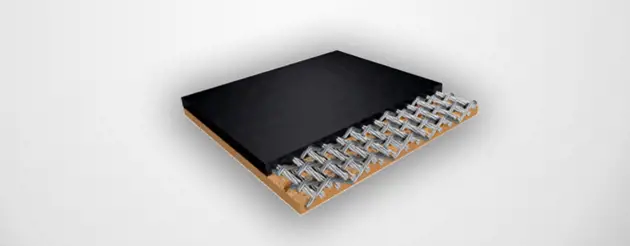

Increased pressing in combination with the plain NTT belt gives significant energy savings while at the same time it provides a very high softness.

Machine capacity

1,800 m/min

Speed in textured mode

2000 m/min

Speed in conventional mode

350 tons/day

Highest production capacity

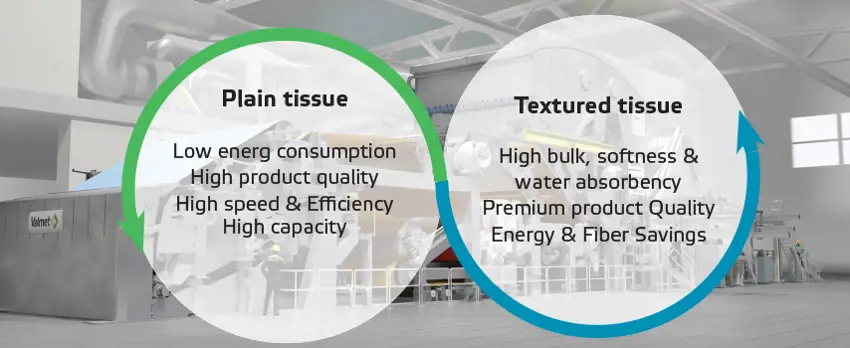

Best of two worlds

The NTT machine can operate in two different modes, one as plain or conventional mode making products similar to conventional dry crepe DCT, the other producing textured products with high bulk.

The technology is easy to operate, has high machine efficiency and operates at high speed. It is particularly suited for production of premium quality bath, towel, facial and napkin grades from virgin or recycled pulp.

Plain mode at high speed

In the plain or conventional mode it is possible to produce very high volumes of tissue products with high softness at low energy consumption. Making products similar to conventional dry crepe DCT. A high production rate of 2000 m/min can be achieved.

The energy consumption in plain mode it is comparable or lower than other conventional tissue making processes

Textured tissue with high bulk and less fibers

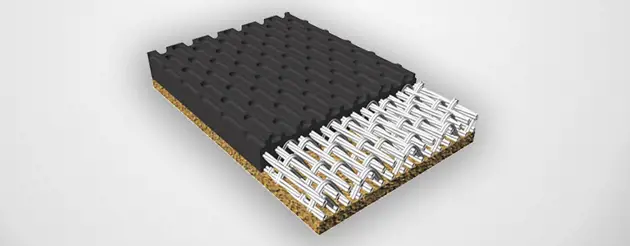

Textured mode provides the possibility to produce premium quality tissue with 50-100% more bulk and softness as well as water absorbency. Fiber savings up to 30% can be obtained due to the increased bulk.

The energy consumption in textured mode is significantly lower compared to the TAD process. With the Advantage NTT process in textured mode it is possible to achieve both high bulk and high dryness at the same time.

Design your unique patterns in pilot trials

The Tissue Technology Center gives you access to a full sized pilot Advantage NTT machine, well equipped and organized laboratory as well as our wide technology and process expertise. We provide a creative environment for developing and testing unique textured patterns, new products, improve product quality and machine performance.

Book your pilot trialA dialogue with data to improve the performance

Valmet Industrial Internet offering covers an extensive range of solutions and applications for tissue mills in order to optimize the full scope of the production. The data driven applications and services support you throughout all the phases of the tissue machine’s lifecycle.

As a start we normally explore the potential of utilizing data through a data discovery process. Then we can evaluate what applications within production capacity, quality, energy efficiency and reliability, are beneficial for your operation. Further, our expertise is easily available for you through the Valmet Performance Centers (VPC). Our specialists have a deep understanding of machinery, processes and automation and with connections and tools, we can offer the needed remote support and guidance without delay from our 8 centers around the worlds.

Download our VII guidebooks

What is the Industrial Internet? What do you need to know about it? And how can you make it work for you? We have prepared guidebooks to open up the most important elements of the Industrial Internet and to explain why and how data can benefit your business.

Get your guideQuestions and answers about Valmet's Advantage NTT technology

Q: How does Advantage NTT technology improve tissue quality?

A: NTT enhances tissue quality, such as softness, strength, and absorbency compared to conventional tissue making techniques. The user has the benefit of being flexible and optimize quality with different textured belts to create bulky papers or make use of the plain mode to get some quality improvement. All at better energy efficiency compared to conventional and shoe press technologies.

Q: What are the advantages of the NTT process in terms of production efficiency?

A: There is an opportunity to operate at higher speeds compared to traditional processes. The process is also designed to optimize energy usage by utilizing high linear load shoe press, advanced drying techniques, heat recovery systems, and other energy-saving innovations.

Q: What flexibility does NTT technology offer in terms of product customization?

A: Tissue makers have the ability to produce a diverse range of tissue products, including all available tissue grades, all basis weights range, and sheet characteristics. This versatility allows manufacturers to respond quickly to changing market demands and customer preferences, optimizing production efficiency and maximizing revenue opportunities.

Q: What support and expertise does Valmet provide for implementing and maintaining NTT technology?

A: Valmet supports with services, technical assistance, training programs, and maintenance offerings. For implementing, the Research & Development team will be glad to provide pilot trials for defining grades, evaluating new products and/or test own resources and raw materials for this unique technology. As part of the start-up package, it is possible to add technology and NTT process training, Valmet Performance Center and Industrial Internet solution for further remote support, troubleshooting and production to quality optimization. There is also a unique NTT user club for those operating the machine.