Lignin business development with Valmet

Valmet can support the development of your lignin business, all the way from the very first tests to full-scale production.

Feasibility studies

A study is an ideal way to start building knowledge. Valmet can assist in clarifying the feasibility and options for lignin extraction, identifying the main lignin characteristics, and developing ideas for possible business opportunities.

Production of lignin samples

Valmet has small lignin extraction units that can be relatively easily set up in a pulp mill. These units produce up to a few kilograms per day.

Small-scale production of lignin provides valuable information on the lignin qualities that can be produced at the mill, possible lignin markets and options for lignin extraction.

Building customer networks

Pulp producers who want to explore the lignin business can do so with LignoBoost XS, a small-scale LignoBoost plant with a capacity of up to 500 tonnes of lignin per year. The plant is delivered in modules for easy transportation and installation.

The latest LignoBoost XS was delivered to Mercer.

The first company to install LignoBoost XS was Klabin. Read more about that delivery here.

More information on LignoBoost XS can be found here.

Commercial scale plants

Valmet has built two commercial scale lignin production plants.

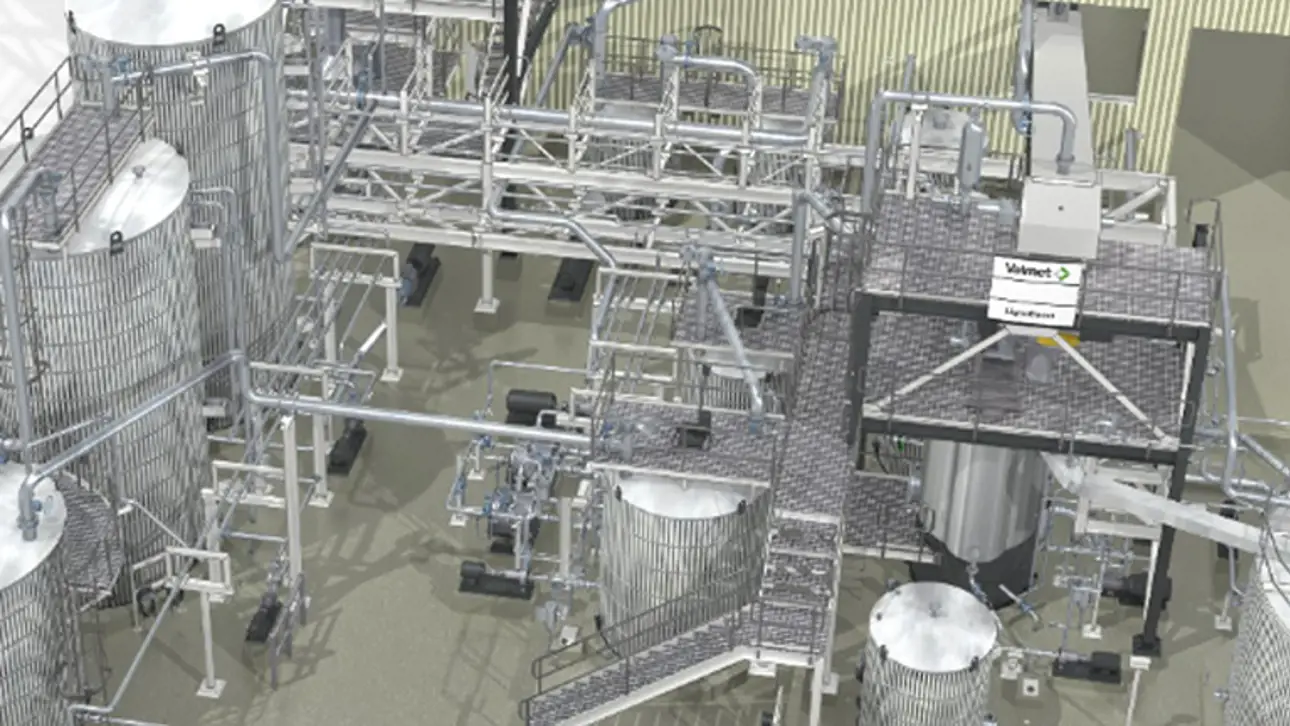

The picture to the right shows the LignoBoost plant at Domtar Plymouth mill, USA.

The biggest LignoBoost plant Valmet has built to date was delivered to Stora Enso’s mill in Sunila, Finland. This delivery included a lignin dryer and equipment for handling and transporting lignin. Lignin was sold and used as fuel in the lime kiln.

More on LignoBoost

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us