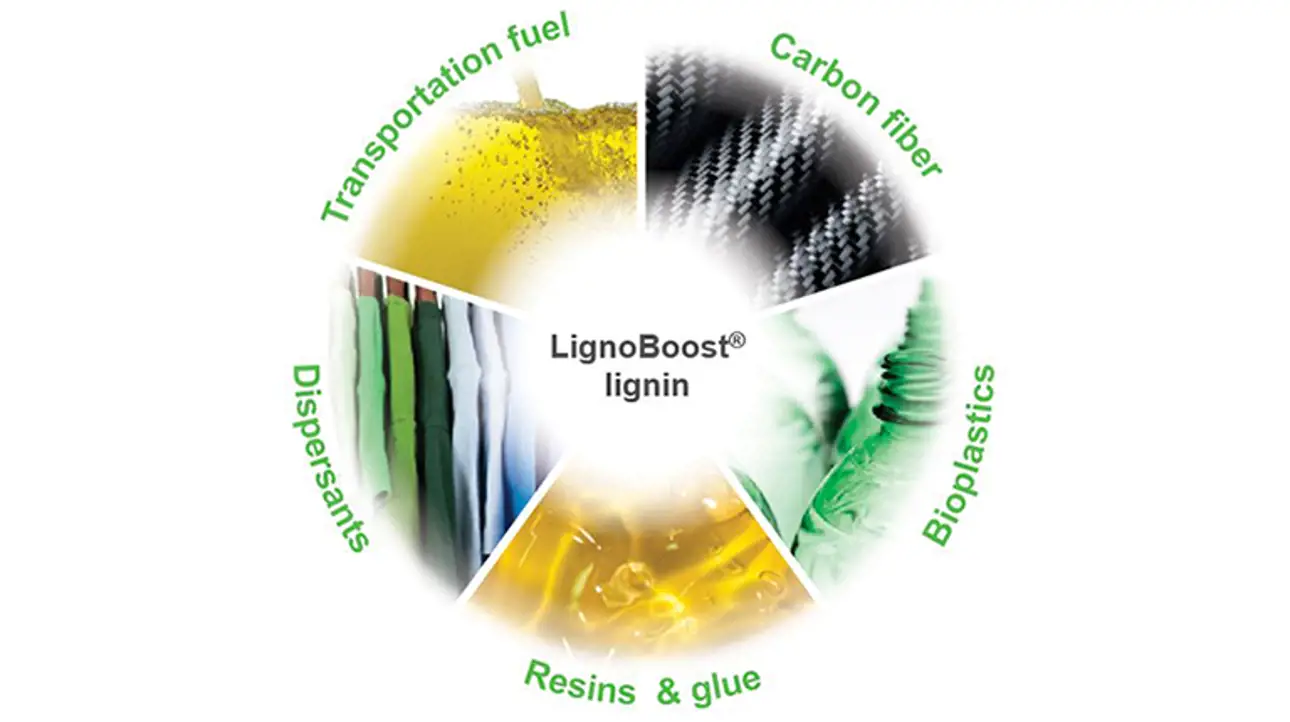

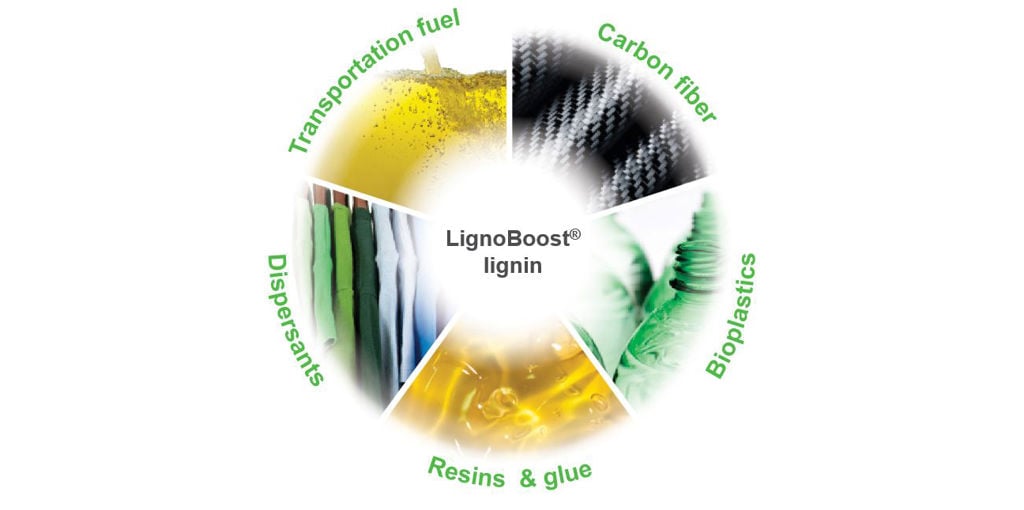

Uses of lignin

Lignin is a renewable material made of much the same chemical building blocks as those found in petroleum-based materials. This means that lignin can be used in a multitude of different products. And since lignin is a renewable material, using lignin will lower emissions of fossil CO2. In addition to lowering the carbon footprint of a product, lignin can sometimes even improve the qualities of the end product.

Stora Enso

Stora Enso has developed many different applications where lignin can be used. One interesting example is lignin in batteries.

Lignin from Stora Enso is a high purity kraft lignin with great dispersibility and reactivity in chemical formulations. For more information, see Stora Enso’s web page on lignin.

100% bio-based furniture board

The Finnish plywood manufacturer Koskinen has started using Stora Enso's lignin-based binder NeoLigno® in production of furniture board. The new board is entirely bio-based and is called Zero Furniture Board. More information on Stora Enso's web site.

UPM BioPiva™

The forest industry company UPM has together with partners developed a rigorously tested portfolio of bio-based lignin solutions. The offering contains is a cost-effective and tightly quality-controlled range of sustainable lignin products. More information on UPM’s website. UPM cooperates with Domtar.

Domtar

In 2013, Domtar started the world’s first commercial LignoBoost plant at the Domtar Plymouth mill in the USA. Today, Domtar cooperates with UPM.

Lignin in plywood

Several million tons of plywood is produced every year, and plywood is used in construction, furniture, packaging and other products that have a relatively long lifetime. Plywood is therefore a good example of a product that binds carbon.

Latvijas Finieris is a leading developer, producer and supplier of birch plywood. Latvijas Finieris has, together with Stora Enso, developed the use of lignin-based plywood resins. The resulting plywood products have a reduced carbon footprint with maintained technical performance. This is a great example of the successful development of renewable bio-based solutions.

High-quality interior applications

Lignin has been successfully used in panels for high-quality interior applications. You can get more information on Arpa’s website, and the Wageningen University and Research website. It seems a lower carbon footprint and outstanding design go well together. As Arpa puts it: Long live the design!

Bioplastics - RENOL®

Lignin Industries (Ren Com) is a company that converts lignin into RENOL®, a lignin-based polymer that can replace fossil-based plastics. RENOL can be blended with most existing thermoplastics, and three application areas are currently being targeted: films; infill for artificial football pitches; and injection-molded products. A major benefit of RENOL-based films is that they are more biodegradable and generate zero microplastics. Another is that every kilogram of fossil-based plastic that is replaced with RENOL saves five to six kg of CO2 emissions. More information can be found on the Lignin Industries website, lignin.se.

Bioplastics - LIGNISOL® and LIGNISET®

RenFuel provides technology for the plastics LIGNISOL® and LIGNISET®. LIGNISOL® is a thermoplastic polymer, blendable with most commercial thermoplastics and with crude or recycled fossil plastics to increase the biobased content. They can be used in conventional extrusion and injection molding. LIGNISET® is a thermoset lignin polymer. It can be used as a functional, biobased resin in fibre-reinforced components, with its properties being tailored depending on the application. The composites can be produced by various hot-pressing techniques.

Car interiors

Car interior details and many other items can be made from a plastic called ABS (acrylonitrile butadiene styrene). The total world production of ABS in 2018 was around 11 million tonnes. The company Prisma Renewable Composites has developed and licensed technologies for making ABS and other high-value composites and polymers from lignin. According to Prisma, their ABS plastic replacement material costs less, has higher tensile strength, higher UV resistance and lower VOC levels than standard ABS resins. Prisma collaborates with industrial partners like Yanfeng Global Automotive Interiors, a supplier of high-quality automotive interior solutions.

Bio-asphalt

More than 1 trillion metric tonnes of asphalt is produced every year. Asphalt is typically made of 95 percent mineral aggregates and 5 percent binder. The binder is normally made of bitumen, which is produced through distillation of crude oil.

One way to reduce the carbon footprint of asphalt is to use a renewable material to make the binder. Lignin has been tested, and the results are positive.

Some reports of lignin in asphalt can be found here, here and here. According to Stora Enso, their Lineo™ lignin has already been used in several projects in Central Europe.

Transportation fuels

Lignin can be converted to regular petrol and diesel, as well as fuels for aviation or marine vessels. RenFuel provides the technology for bio-oil LIGNOL®, that can be mixed with any crude or vegetable oil and hydrotreated in a refinery to give give petrol, diesel, aviation and marine fuels fully compatible with conventional fuels. Compared with pure HVO, LIGNOL® fuels offer a lower price at the pump, extended feedstock availability and a high GHG reduction. LIGNOL® is a viable contributor to meeting the mandates of EU’s Renewable Energy Directive (RED II/III) for transport fuels.

Upgrade lignin with enzymatic technology

MetGen combines synthetic biology with chemistry and process engineering to enable better utilization of raw materials and increase the use of bio-based materials. MetGen has advanced plans for several lignin-based products, and offerings for biorefineries and fiber solutions.

Other uses of lignin

Chemical industries offer many other possible and profitable uses of lignin. Some examples are chemical products like adhesives, polymers, polyols, sizing, coating and emulsifier agents.

These products, as well as the ones listed above, have a combined volume that is in the range of millions of tons per year. This means that lignin has many possible uses. And using lignin to make them is a great way to lower the use of fossil-based materials.

More on LignoBoost

Our expertise is at your service

Our focus is to bring your performance forward and ensure sustainable pulp production utilizing our extensive experience and in-depth technology knowledge. If you want to know more, get in touch with our chemical recovery specialists. Contact us through your local Valmet office, or the link below.

Contact us