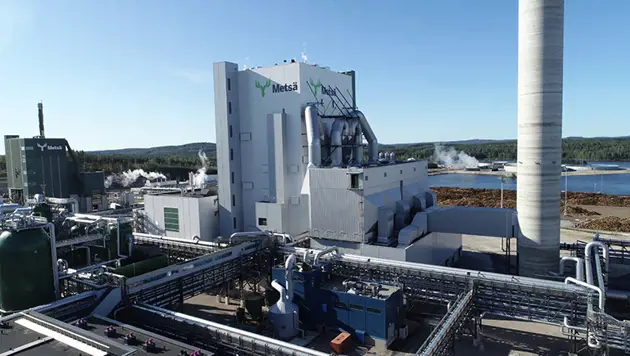

Process upgrades for chemical recovery solutions

Cost effective and circular way to reach new recovery boiler and evaporation performance targets

High-yield, low-cost qualitative rebuilds and upgrades can help you stay competitive, achieve environmental goals, and increase the service life of your recovery boiler and evaporation plants by costs far below those of new construction.

Improve capacity

Extend lifetime

Improve environmental performance

Allow fuel flexibility

How to raise the production efficiency or quality to the new level and at the same time lower the maintenance costs?

Process upgrades are small or mid-size investments that opens up production bottlenecks or extends the original process design limitations. Typical process upgrade building blocks are design engineering, new components, new machine and process controls and efficient commissioning and start-up services.

Upgrades to increase capacity, protect the environment and allow fuel flexibility

Valmet's goal is to maintain the competitiveness of our customers' core processes and to develop them throughout their lifecycles. Valmet provides energy producers with a wide range of solutions for upgrading and enhancing processes and machinery. The scope is always based on each customer’s specific needs and tailored solutions to maximize the performance of different processes.

Upgrades based on experience to increase capacity & save the environment

Valmet's expertise and experience is incorporated in all our products, giving us unparalleled insight into all aspects of upgrading processes and machinery. We are committed to continuously researching and developing new technologies, materials and designs to enhance the performance of existing equipment and processes.

We support you with process and equipment upgrades to your CFB and BFB boilers to:

- Improve capacity

- Reduce emissions

- Extend lifetime

- Ensure availability

- Enhance energy efficiency

- Improve water circulation

- Allow fuel flexibility

We have all the necessary know-how, based on experience and resources, to manage complete projects and provide you with expert assistance, within the shortest possible time frame

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usMore than 200

upgrades delivered for power and recovery boilers worldwide

Circular solutions to convert old boilers and plants and extend the lifetime

Another possibility to meet new requirements is to convert an old boiler to fluidized bed technology. A customized rebuild can often increase the service life of a recovery boiler, an evaporation plant, or a power boiler by ten to 15 years, at costs far below those of new construction.

The main incentives for converting a boiler (CFB or BFB) is fuel flexibility, the possibilities to switch to biomass firing and fulfill stricter emission limits. By converting an old boiler, the investment cost will be far lower, with a faster delivery schedule (about half the delivery time for a new boiler), and easier building permit.

We have the experience to convert several types of boilers:

- Grate-fired boilers

- Pulverized coal boilers

- Recovery boilers

Evaporation plants upgrade

Valmet offers evaporator technology that provides maximum availability and productivity, minimized operation and maintenance costs - all while complying with strict environmental standards.

• Increased evaporation capacity

• Increased dry solids capability

• Improved operation

• Optimized steam economy

• Improved condensate quality

Safe and reliable cleaning of recovery boiler smelt spouts

Efficiently removes smelt deposits from recovery boiler smelt spouts in a carefully designed sequence. Valmet Smelt Spout Cleaning Robot ensures stable smelt flow, optimum cleaning and trouble free, safe boiler operation. The robot will keep your smelt spouts clean, saving you time, money and allow safer work environment for your team.

Find out more about our latest installation at Pixelle mill in Spring Grove Pennsylvania, in North America

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}