Modernize evaporators for significant production cost savings

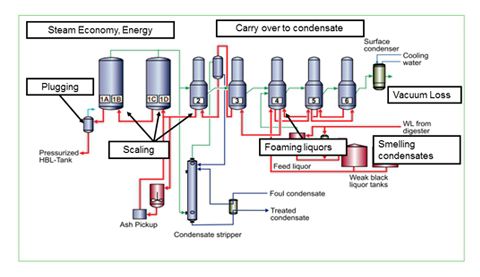

You're already well aware that evaporators are the biggest energy hogs in your pulp mill. And while the evaporators may cost you most in the energy department, they can also be where you would see the most savings in production costs. These savings can be achieved when you modernize the evaporators, making both them and the entire mill more efficient and reliable. These benefits include steam economy, condensate segregation, and scaling and availability.

Steam economy

Many older evaporators only have 5 thermal effects and some do not have the concentrators integrated into the evaporators at all! Modern evaporators normally have 6-7 thermal effects. Based on the cost of energy for an average North American mill, the savings from upgrading from 5 thermal effect to 6 thermal effect, could be in the area of $1.9 million. More so, upgrading from 5 thermal effect to 7 thermal effect could offer a $3.3 million saving.

Condensate segregation

Energy savings can also be found by improving the quality of the condensate from the evaporators. Condensate is contaminated by methanol, and that methanol will be released during the initial evaporation process. By producing a larger amount of clean condensate in the back-end effects through internal condensate segregation, it can be reused in the pulp mill. Modern pulp mills reuse all secondary condensate, reducing water consumption.

Scaling and availability

Scaling is something we know you would like to avoid. The plugging of equipment, increased energy costs and especially lost production due to the downtime are things we all want to avoid. Modernizing your evaporator can greatly reduce scaling.

There is no need to buy a new evaporator, when the one you own can be upgraded. Let the experts at Valmet be your guide to upgrading your pulp mill to be more productive and energy efficient. Contact your Valmet representative.