More than 4 GWh in annual energy savings

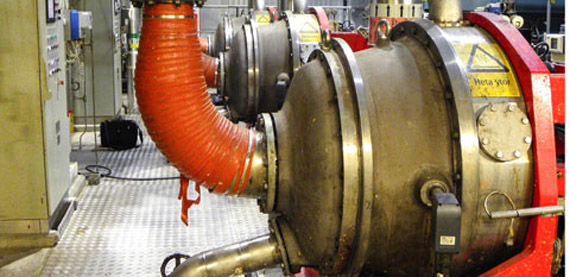

When Stora Enso initiated a project in 2012 targeting a reduction in energy consumption in the TMP refining process, staff at the Hylte Mill called on Valmet for help. Valmet recommended installation of an Adjustable Gap Sensor (AGS) on each of the three Valmet conical low consistency refiners of type Conflo CF82, installed after the mainline high consistency refiners in 2003.

Short Return On Investment

Hylte and Valmet agreed on a guaranteed energy saving of 15 kWh/admt (air dry tonnes) of produced pulp. While working in close collaboration with each other, they hit the bull’s eye. For Hylte, this means a Return On Investment (ROI) of less than one year. What’s more, the saving has been carried out without sacrificing TMP pulp quality. In fact, according to Patrick Nordin, superintendent, mechanical pulping, and Stefan Snygg, the project leader, the project has resulted in significantly greater pulp uniformity. Currently, Hylte and Valmet are working on even more ways to save more energy.

The task of the Conflo CF82 refiners is to further refine the TMP pulp to paper machine specifications. The installed AGS enables the refiners to run with an optimal constant disc gap via automatic recalibrations during production with a precision as exact as 0.25 hundredths of a millimeter.

Hylte Mill installed an Adjustable Gap Sensor on each of the three Valmet conical low consistency refiners of type Conflo CF82.