Heat storage requires high system availability

When Vaasan Voima chose automation to control its new rock cavern heat storage – the largest of its kind in Finland – high system availability was the top priority.

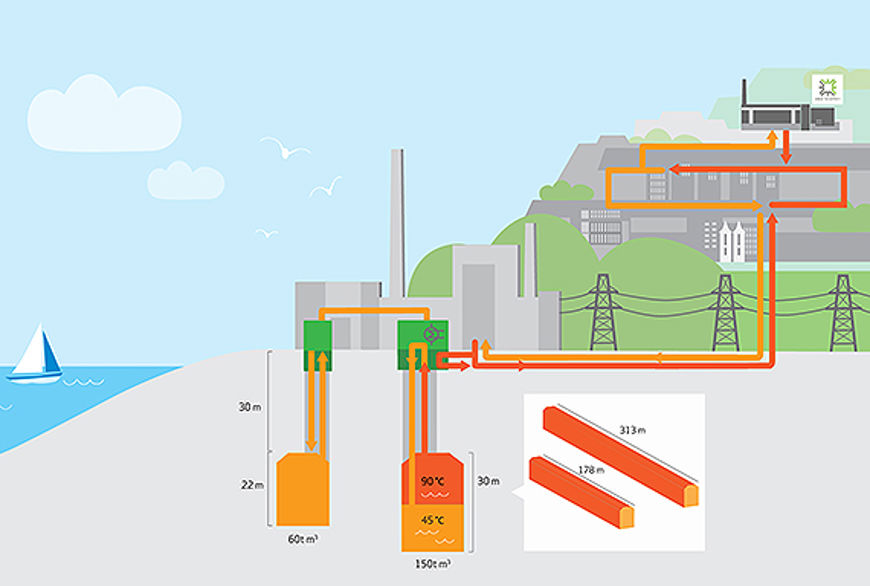

Rock storage caverns located at a depth of thirty metres were turned into a heat storage facility at Vaskiluodon Voima CHP plant.

There is much more than meets the eye at Vaskiluodon Voima’s combined heat and power plant site in Vaasa, on the western coast of Finland. Underground, some 30 meters deep down in the bedrock, there are two caverns that were decades ago used to store oil. They have been emptied, cleaned up and now converted into massive heat storage with a total volume of 210,000 m3. The storage will be charged with heat from the adjacent CHP plant and excess heat from West Energy’s waste-to-energy plant on the other side of the city. Everything is almost ready for the test runs that will take place in fall 2020.

With a charge and discharge capacity of 100 megawatts, the facility is able to store 7,000–9,000 megawatt hours of energy. This is a thousand times more than the storage capacity of the largest electricity storage currently under construction in the Nordic countries.

“Our heat storage capacity will be enough to cover the district heat need of Vaasa for four days during the cold winter months or up to two weeks in the summer,” describes Janne Österback, Production Manager at Vaasan Voima. “The heat storage will enable us to reduce the use of coal in our district heat production. Most importantly, it will significantly improve the efficiency of the Vaskiluoto 2 unit as we can run it more optimally with regard to the electricity market, and we can even out district heat demand peaks.”

The Vaskiluoto power plant has a capacity of 230 MW of electricity and 175 MW of district heat. There is an advanced 140 MW biomass gasification plant supplied by Valmet next to it, the first of its kind in the world. It gives the plant the ability to replace about a third of the coal used with domestic biomass.

Heat storage at Vaskiluodon Voima’s CHP plant in Vaasa.

“We knew exactly what we would get”

According to Österback, automation plays a significant role in the new heat storage to optimize the plant’s heat production. This is why so much attention was paid to get a solution that meets the high expectations.

To automate, control and monitor the heat storage, Vaasan Voima had two alternatives: either to expand the existing Valmet DNA automation system at the Vaskiluoto plant by adding a new Valmet DNA process station or choose a third-party stand-alone PLC system. “We wanted to have a separate system that can be operated both from Vaskiluoto 2’s control room and remotely from a third-party system that is used at Vaasan Sähkö, the local electricity company who is the other investor in this heat storage,” Österback explains.

By choosing Valmet’s automation, we knew exactly what we would get: high system availability – just what we wanted. We have been cooperating with Valmet since 1998, and during this time we have accumulated a vast amount of in-house knowledge of the company’s automation system. Our staff knows how to run and upkeep it.”

Valmet’s automation solution features a redundant PROFINET communication protocol over Industrial Ethernet for the motors, pumps and measurements underground. “There are only few similar deliveries in the world. Redundancy improves system availability and reliability,” points out Teemu Mannila, Project Manager at Valmet.

On schedule despite the coronavirus pandemic

The schedule of the project was tight, and the final stage coincided with the coronavirus pandemic. “Actually, it did not affect us very much as we were able to carry out much of the project online through Valmet’s secure remote connection to our plant. We are used to working together online,” Österback adds. “Our cooperation with Valmet was very good, and Valmet’s professionals carried out the project in a very straightforward way.”

Österback and his colleagues in Vaasa now eagerly wait for the next heating season to start to see how the new heat storage and its new automation fully operate.

For more information, please contact:

Jorma Kosonen, Sales Manager, Services, Valmet

jorma.kosonen(at)valmet.com

Vaasan Voima is part of EPV Energy Group, a Finnish energy company that generates and procures approximately 5% of all the electricity consumed in Finland. EPV Energy is a forerunner in low-emission and renewable energy. At EPV Energy, we have greatly improved our range of energy generation, resulting in significant reductions in carbon dioxide emissions and we aim to achieve carbon-neutral electricity generation by 2035. EPV Energy has almost 70 years’ experience of responsible energy generation. EPV Energy’s turnover in 2019 was MEUR 343 and we employed 101 people.