Valmet's flow control is widely recognized as a holistic supplier of valve technologies. Valve automation, that is to say valve controllers, limit switches and digital services, are an important part of our offering. Especially in increasingly digital industrial environments, these devices play a key role in delivering true added value to valve operations.

Digitalization embedded

An industrial valve, whether it is Neles™ or a different brand, will always benefit from the intelligence and connectivity that our valve automation offering bring to the table. Digitalization is truly embedded into our valve automation portfolio. The terminology surrounding digitalization – IoT, industry 4.0, big data etc. – continues to become an active part of our vocabulary. It is worth remembering that these are exactly the things our top works and digital services are designed to help you achieve or utilize in your business.

From information to insight

New plants being built today are not looking to digitalize their assets only for process control purposes anymore. Instead, they are looking for every opportunity to extract and utilize process data and improve performance. New data-driven ways of working unlock the implementation of new and smarter improvement programs such as inventory management, control performance, field device management and shutdown planning among others.

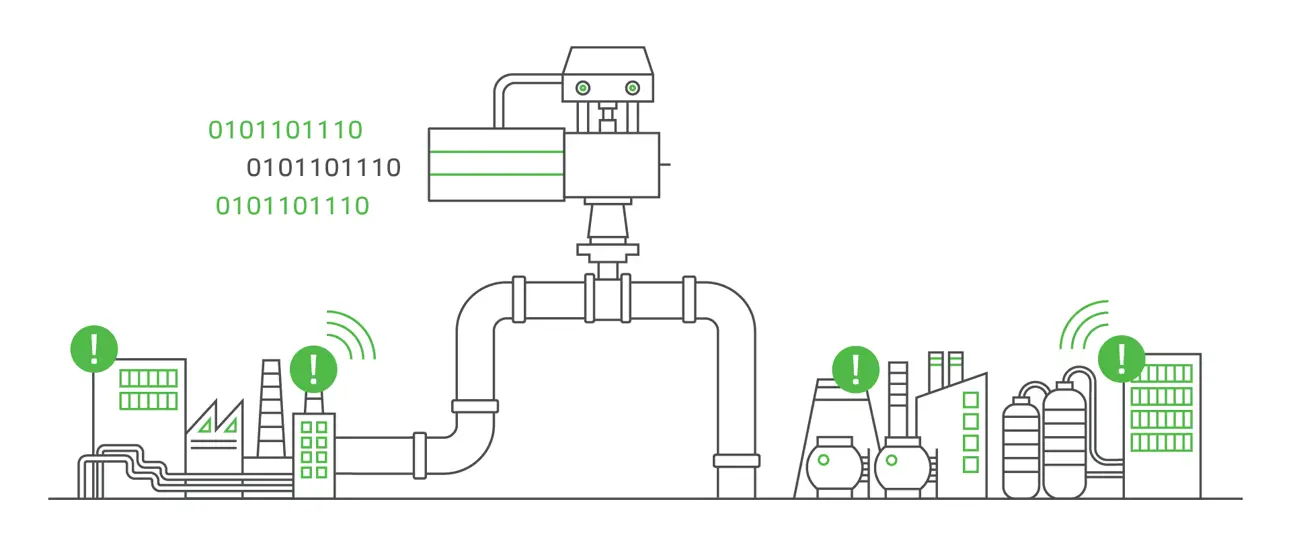

None of the components of the mechanical valve itself can provide valuable data about themselves. It is the powerful combination of valve automation devices like intelligent valve controllers, device- and plant-level software and our team of service experts that can collect and interpret performance data to provide information about valve performance and condition.

Digitalization and automation are not in themselves something our customers are buying. What they are after are the benefits and added value that can be achieved through increasingly intelligent valve automation. This means that they are paying for the insights that enable better shutdown planning, efficient spare parts inventory, better process control and the minimization of risks. In the end it is all about reliability and that is what our valve automation and digital services offering are ready to provide.

Connectivity and communications

The connectivity of intelligent valve automation devices also allows for remote access and configuration. This not only improves safety by minimizing the need for people to carry out visual inspections and manual configurations on-site. This also improves accuracy in most cases for the exact same reasons. Minimizing the risk of human error is still a key driver for digitalization today. In the post-pandemic world, we can expect that limiting physical interactions will become even more the norm.

Intelligent and connected valve automation devices also allow vendors like ourselves to gain remote access to your process data, allowing us to proactively provide insights, recommendations, parts and even remote digital services. Our devices have always, and will continue to, provide communications based on all common protocols. In addition to the common protocols such as HART, Profibus and the likes, we are also continuously adopting and developing new protocols and technologies. We are actively working with technologies such as Bluetooth, Ethernet APL and Cloud solutions which are actively making their way from the commercial side into the industrial world.

Digitalization is a journey

Our valve automation portfolio addresses the digitalization needs of today and is committed to continuous development that will give our customers a competitive edge. We recognize that each industrial customer is at a different stage of their digitalization journey. While some are only getting started, others may be at a very advanced stage. Also, customers with multiple plants may find different plants being at different stages.

We provide customized valve automation solutions and services to every step of the digitalization journey. We can help you get started, or dive deep into the world of data utilization for improved process performance, if you are already further along the path. We help our customers extract significant results, which typically acts as justification for further investments into the next level of digitalization.

The text has been updated in April 2022, due to the company name change to Valmet.