Steam shower practical tips and the Valmet IQ Steam Profiler

If a steam shower is to be used it may require a cover which is more heat resistant, and possibly harder P&J, due to the higher temperatures associated with the steam shower.

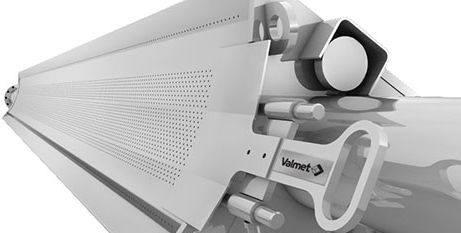

Valmet IQ Steam Profiler is the highest efficiency steam profiler family to increase production capacity, decrease energy consumption and improve moisture profile

The shower should not impinge directly on the roll cover.

Excessive steam should not be applied outside the sheet width or in a localized area.

Thermal shock should be avoided during startups. This is most important near unfelted center roll positions.

Automatic controls should assure shutdown of the steam showers when rolls are not turning.

Roll covers may have to be reground more frequently due to more rapid heat aging.

Steam showers should not be used on suction rolls when the vacuum is not in use or the felt is not in place.

Rolls installed near steam showers should be checked each shutdown for surface condition, i.e. hardness and crown.

The steam should not impinge directly on the felt or roll edge.

The adjustable vacuum deckle should be moved to a point in line with the sheet edge (vacuum should not extend beyond the sheet edge).

A low pressure lubricating shower may be applied outside the end deckle to cool the suction shell ends and prevent excessive thermal expansion outside the sheet area.

Valmet IQ Steam Profiler improves moisture profile and increases capacity

IQ Steam Profiler is a multi-zone steam actuator system that provides unique profiling accuracy through its electromechanical actuator with position feedback. This reliable, high-performance steam profiler system features advanced steam injection technology, that maximizes steam absorption efficiency and temperature increase, providing the highest dryness after the press.

Valmet IQ Steam Profiler

The benefits gained with IQ Steam Profiler have been excellent. For example, at paper mills that use IQ Steam Profiler, the moisture 2-sigma has typically decreased by 80%, and the dryness after the press section has increased by 3-3.5%, sometimes even more. This superior dryness with a moisture profile 2-sigma of less than 0.1% would enable a production speed increase of more than 10%. Even with moderate results, the payback period for IQ Steam Profiler can be a couple of months.

For assistance with steam shower setup and use and more information about Valmet steam profilers, contact your Valmet representative.