Maximizing safety and prevent accidents in knife-changing work with EasyTurn

Valmet emphasizes the importance of occupational health and safety in all activities related to its products and operations.

One of the operations containing risk in the wood handling process is the work involved in changing chipper knives.The logs arriving at the pulp mill are debarked and chipped before entering the pulping process. The quality of chips is essential in producing high-quality pulp. To make sure that chip quality remains the best possible, chipper knives must be kept in a very good condition.

A typical Valmet chipper has 15 knives installed on a chipper disk.

When changing the knives, the chipper disk is normally turned to the correct position manually. Turning a disk, which weighs up to 15 tonnes, creates so much kinetic energy that there can be the risk of injury. Turning the disk manually also requires a lot of physical force, which can be a risk factor in itself. For this reason Valmet has a solution for further maximizing safety at work. Valmet studied and tested various alternatives that would prevent any accidents in knife-changing work. Finally, the best solution turned out to be the product that was released on the market under the product name EasyTurn.

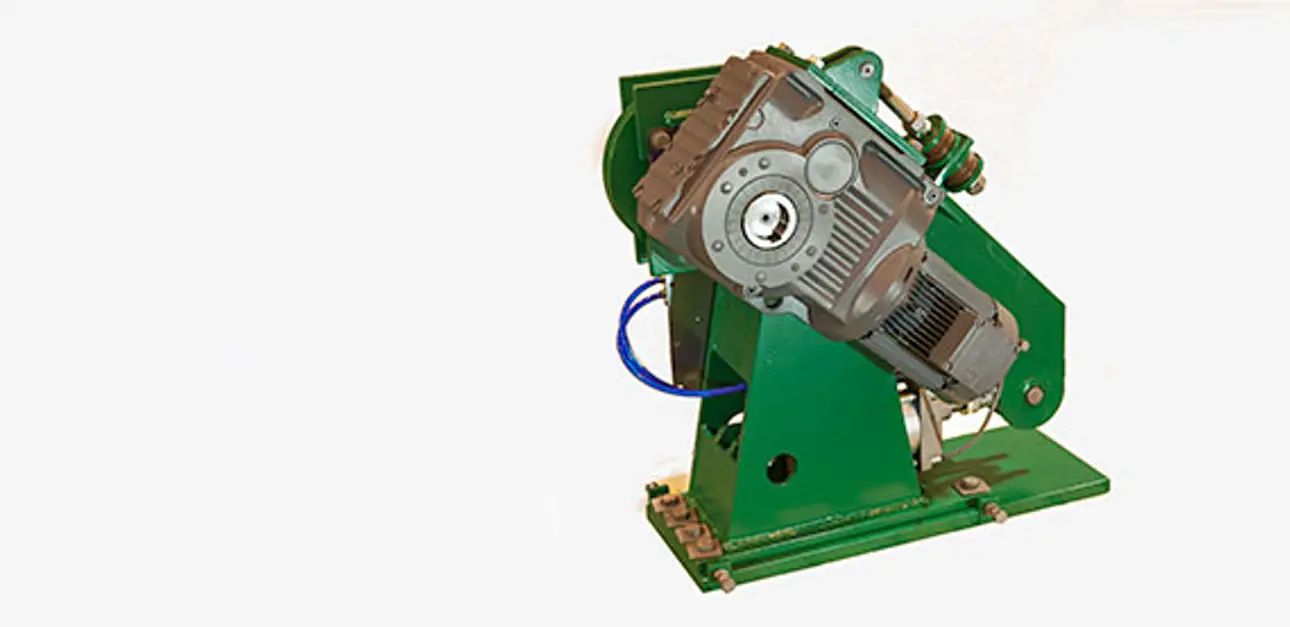

EasyTurn operation principle

The EasyTurn device is mounted between the motor and the chipper disk and it features variable speed drive and a drive wheel. The drive wheel can be pushed pneumatically onto the chipper’s break disk to turn the chipper disk. The chipper disk is remotely rotated to the correct position for knife change using a joystick on the control desk.

Operation experience

The experience gained with EasyTurn installations so far has been extremely positive. EasyTurn systems were installed for two Valmet chippers at a customer mill. Every day the equivalent of 140 tandem trailerloads of logs arrive at the mill. All the wood raw material for the pulping process passes through these chippers. To keep the chippers continuously in top condition without risking occupational safety is a challenging job. The knife change operation on both chippers is now carried out safely with the help of EasyTurn. Experience shows that, often when new methods are introduced, some people would rather do their job the old familiar way until they get used to the new one. However, with regard to EasyTurn, all operators have started to use this new method from day one. The safety statistics from the installations in operation show that there have been zero injuries related to changing chipper knives since the introduction of EasyTurn.