Reliable condition monitoring secures transition to carbon neutralilty at Oulun Energia’s biopower plant

Oulun Energia’s Laanila power plant relies on Valmet’s plantwide DNA Distributed Control System (DCS) to run its plant operations. Valmet DNA condition monitoring, an integral part of the system, ensures safe and smooth operations for each machine, based on their criticality and field conditions.

The city of Oulu in Finland aims to be carbon neutral by 2035, and local energy company Oulun Energia shares this goal. In relinquishing fossil fuels, the company will gradually reduce the use of peat as an energy source. It will be replaced by wood pulp and nonrecyclable waste fractions.

The Laanila biopower plant, which opened for commercial use in 2020, plays an important role on the path to carbon neutrality. Its operations are characterized by optimal fuel flexibility and the utilization of various sidestreams.

The power plant serves the growing city of Oulu’s energy needs. Its production capacity is 75 megawatts of electricity and 175 megawatts of district heat. If necessary, process steam can be supplied to the industrial facilities in the nearby Laanila area.

Valmet DNA condition monitoring system was a natural choice

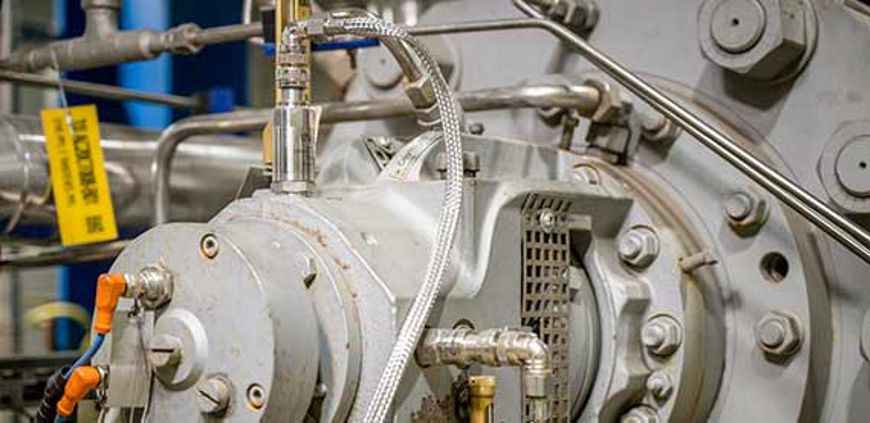

The plant’s operation is controlled and monitored by the Valmet DNA Distributed Control System (DCS), which also includes applications for safety, information management, emissions monitoring and calculating the power plant’s key figures. The automation system and Valmet Industrial Internet applications optimize the plant’s operations in real-time. Vibration condition monitoring is a key element of an energy plant’s safe and efficient operations. The Laanila plant’s maintenance is assisted by Valmet DNA condition monitoring, which is included in the Valmet DNA automation system.

“Our goal in the procurement phase was to equip our modern power plant with a condition monitoring system that would be as functional, reliable and versatile as possible. Valmet’s condition monitoring was the best fit for us because it’s part of the plant’s automation system. It’s important to ensure a seamless information flow within the system,” says Tim Onnela, Oulun Energia.

An important criterion for the purchase was to ensure plant operators could smoothly use the condition monitoring system alongside the automation system in daily work. The condition monitoring notifies operators of any deviations and predicts failure situations so problems can be addressed before they cause major damage.

Smooth commissioning

Valmet drew up a condition monitoring plan for Oulun Energia to prepare for the commissioning of the condition monitoring system. This involved planning automatic online measurements, scheduling periodic route measurements and applying them to the full scope of the condition monitoring solution. The commissioning also entailed the definition of the measurements’ alarm limits. “The more critical measurements are now covered by online condition monitoring, and the less critical ones are measured with a portable analyzer. Online measurements are carried out many times a day, while the interval between manual measurements can be as much as four weeks,” Onnela says.

The commissioning of the extensive plantwide condition monitoring system was a pleasant surprise for Onnela. One reason for the success was Valmet’s expert staff, some of whom he already knew, so working with them was effortless. “Collaboration with Valmet’s professionals is seamless. If any changes have been necessary, the issues have been addressed immediately.

Having support close at hand is important to us.”

“The cooperation with Oulun Energia has been a good experience for many reasons. For example, the company’s in-depth condition monitoring expertise and equipment-related knowledge have been invaluable. Oulun Energia also sees condition monitoring as an important part of a modern power plant’s operations that serves both those maintaining and operating the plant. The staff is also enthusiastic and willing to develop new solutions for demanding locations with Valmet. The collaboration has been extremely fruitful,” says Valmet Automation’s Senior Application Specialist Tommi Karsikas.

Successful pilot with wireless sensors

The piloting of new technologies has advanced the cooperation. Among the most interesting was testing Valmet WVS-100 and WMM-100 wireless vibration sensors with the boilers’ feed screws. Installing fixed vibration sensors would have been very difficult and costly. The wireless sensors were tested for a six-month period. Encouraged by the good experience, their use was extended, bringing the plant’s total number of wireless sensors to more than 100 and equaling the number of fixed sensors.

“The quality of Valmet’s wireless sensors is excellent, and they are fast to deploy,” Tim Onnela, Oulun Energia, says in praise of the products.

That said, it is unwise to install wireless sensors in every location because they have batteries that require periodic recharging. Fixed wired sensors are favored for more critical points such as blowers and large pumps.

Experience encourages wider deployment

The common tasks of condition monitoring include entering bearing data into the system and tuning the alarm limits in the context of a process change in the raw material mixture. Valmet’s condition monitoring system makes these measures simple. “Valmet DNA condition monitoring saves a lot of effort because you don’t need to do all the measurements manually.

The condition monitoring system has already saved the Laanila plant significant trouble by detecting a fault in the bearing of a district heating pump motor bearing. If it had been allowed to deteriorate, there could have been severe equipment failure, resulting in costly repairs – another demonstration of the importance of daily automatic measurements.

As the Laanila plant has found the condition monitoring system to be an excellent tool, its deployment is also being planned at the Toppila power and Laanila eco power plants.