Nuclear free basis weight now available for paper

Successfully used to determine basis weight on hundreds of tissue machines, the Valmet IQ Fiber Measurement has been further developed for applications in the production of heavier paper grades.

Papelera de Brandia S.A. in Spain, producing up to 140 gsm machine glazed packaging papers, has reported good results since the August 2020 startup of a new Valmet IQ quality control system (QCS). The scanner mounted Valmet IQ Fiber sensor (patent pending), a key component of the QCS, met Brandia’s need for a basis weight sensor without a radioactive source. “In Brandia, we are dedicating a lot of time and financial resources to our environmental and sustainability policy. We want to be an active part of a better world which is both possible and necessary. Sustainable development goals are part of our concept of a modern company committed to society,” says Javier Vazquez, Technical Director.

Sustainable and safer solution

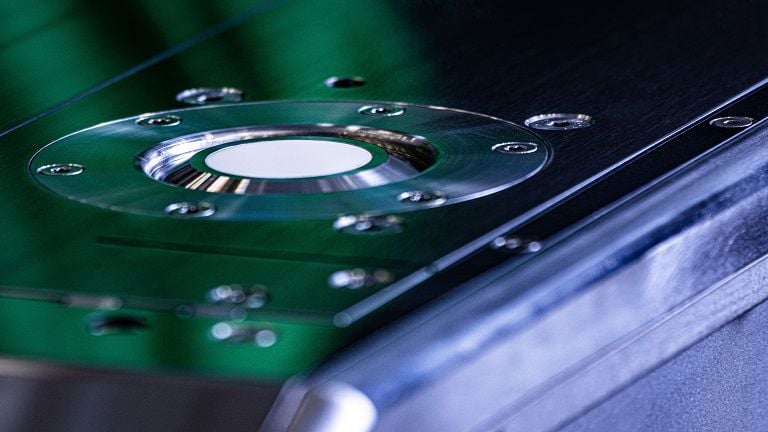

Nuclear-based sensors together with infrared moisture sensors have for decades been the standard for the scanning measurement of basis weight in paper production. In recent years, however, increased public awareness and the introduction of European Union directives concerned with the dangers of exposure to ionizing radiation are forcing a change. Simultaneously measuring fiber weight and moisture, the infra-red-based Valmet IQ Fiber at Brandia replaced the traditional nuclear basis weight sensor and removed the need for the specialized service and fire protection procedures for radioactive devices. A Valmet IQ X-Ray Ash sensor also installed on the scanner now measures the absorption of low energy x-ray radiation to determine total ash and the amount of different ash components in the paper.

“The existence of a Category 2 radioactive facility was a cause of concern for the nearby neighborhood, a concern that has disappeared with the installation of the Valmet equipment. The fact of eliminating the radioactive source and starting to work with X-ray equipment has made it possible to become a Category 3 facility, with all the advantages that this entails, in addition to not having to manage any more changes of end-of-life radioactive sources,” says Vazquez.

Improved controls

At Papelera de Brandia, the accurate scan averages and high-resolution CD profiles measured by Valmet IQ Fiber provide a solid foundation for machine- and cross-direction oven-dry weight controls. The response speed and signal-to-noise ratio of Valmet IQ Fiber are significantly better than the nuclear sensors it replaces. This improves the detection of transient or cyclical variations and adds a significant troubleshooting capability to the system in performing detailed online variability studies and when making process improvements.

“Due to the wide range of grades that we produce we took the decision to maintain the old scanner with the radioactive source and operate both systems at the same time. During the first phase, we kept the quality controls on the old system while all the grades were adjusted to the new system. Later the control was moved to the Valmet IQ QCS and the scanner with the radioactive source was removed. Thanks to that we could guarantee all the time to maintain the quality of the paper produced during the change process,” says Vazquez.

Another successful project!

Good results have been obtained in the 15 months since startup. “At Brandia we are very pleased to have undertaken this project despite the fact that it represented a challenge and there were a few voices that advised us not to change. The process has represented an effort, but with the constant support of Valmet we can affirm that we consider the project a success since the equipment meets our expectations over the entire range of grades that we manufacture,” concludes Vazquez.