Refiner segments for high consistency refining in pulp mills

New-generation low-energy technology for improved fiber quality and optimized refiner operation

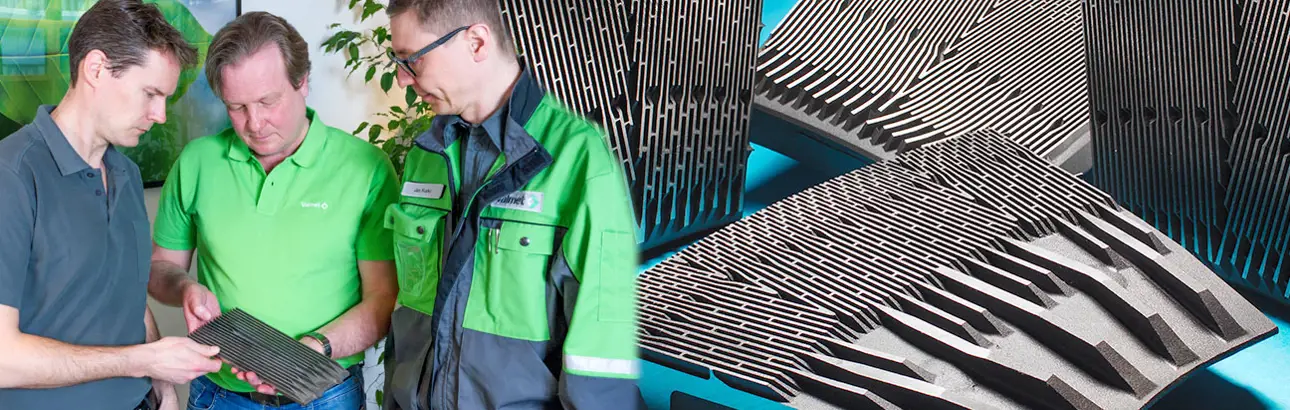

Valmet high consistency refiner segments technologies can be utilized to meet operational targets such as reducing production costs, improving fiber quality or optimizing refiner operation depending on customer needs and refiner operations. During the decades we have gained detailed knowledge of most types of refiners, including Valmet OEM refiners as well as those made by our competitors. Our refiner segment experts are continuously cooperating with customers and commit to optimizing their refiner processes with new technology.

Reduced energy consumption

Improved operational stability

Improved availability

Improved pulp quality

Custom-made refiner segments – Let us be your co-driver for success

In the field of refining, Valmet is continuously developing new refiner segment technology to improve customers’ competitiveness. We offer to our customers an extensive contact network, experienced refiner specialists, effective refiner segment design toolbox with patented features and the most effective research and development support. Our philosophy is that every refiner is unique and needs custom designed refiner segments.

Without Turbine-feature it wouldn’t be possible for us to operate today.”

Read the full customer case:

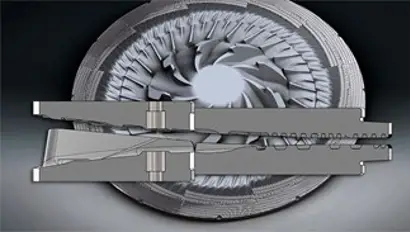

Did you know that Super feed and Turbine segments center plate improves feeding at the eye of the refiner? Download a brochure about Valmet Refiner Segments - Turbine segments.

Solutions for your needs - reduce energy consumption

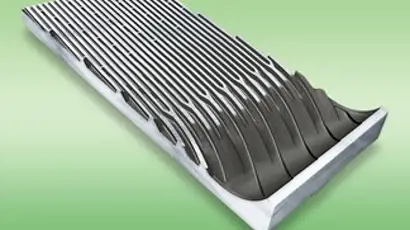

Refiner Segments - Intensive defibration

Innovation to further improve Valmet existing energy saving Refiner Segment product portfolio for reaching 50% energy reduction.

Redmore about Refiner Segments - Intensive defibration.

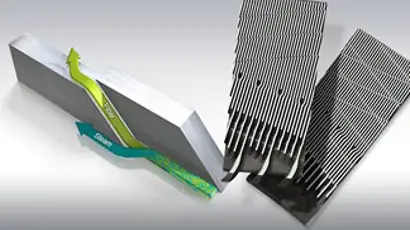

Refiner Segments - Shive Clean

This new technology takes benefit from the fact that in the disc gap steam and fibers are behaving differently. Shive clean to reach top quality CTMP pulp.

Read more about Refiner Segments - Shive Clean.

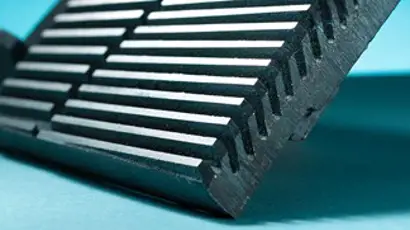

Refiner Segments - Attack bar

Inclined bars for sharper leading edges and cleaner grooves as well as energy saving over segment lifetime.

Read more about Refiner Segments - Attack bar.

Refiner Segments – Quattro feed

Utilizes CD stator inlet in a new way for further improved feeding and more unified fiber distribution.

Read more about Refiner Segments – Quattro feed.

Browse our other products and services to support your fiber quality and refiner operation

Soft bar

Ensuring smooth and gentle feed, leveling out incoming feed variations.