Sustainable technology for structured tissue

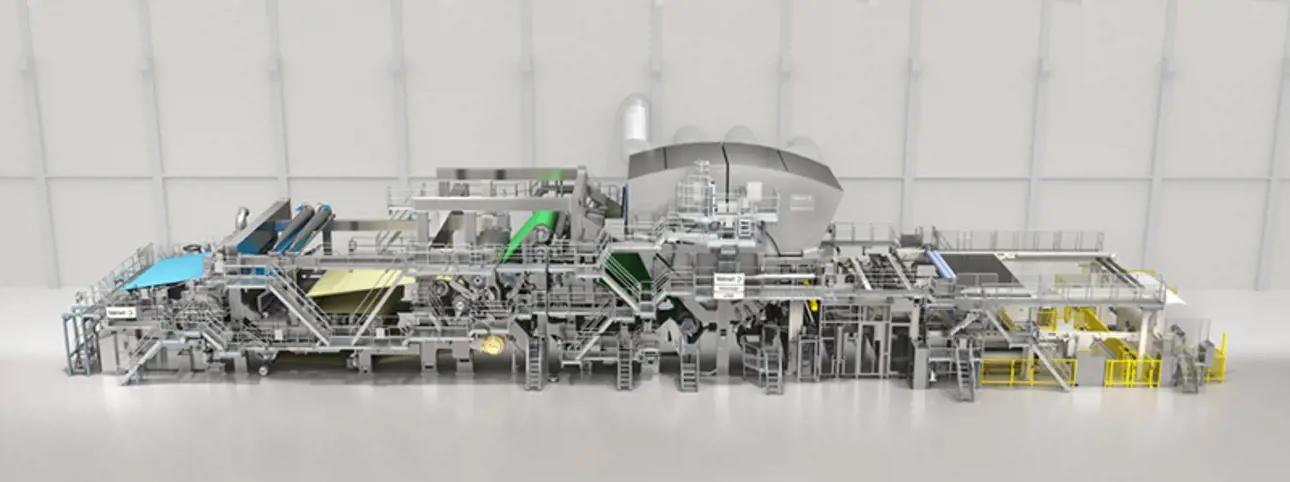

The demand for high quality tissue and towel products is growing. The previous proven receipt to reach the highest bulk and absorbency has been to avoid pressing and utilize through air drying. Valmet can now offer a new way to produce structured tissue with paper characteristics closer to TAD tissue/towel but with significantly lower energy consumption. In addition, the Advantage eTAD technology enables fiber saving opportunities in the production of ultra-premium quality tissue and towel products.

The Advantage eTAD concept which originally was developed by Georgia Pacific is now available to Valmet customers outside Canada, US and Mexico under a license agreement between Valmet and Georgia-Pacific. Advantage eTAD machines are already running in commercial operations producing ultra-premium bath and towel tissue products for consumers in North America.

“We wanted to offer the ability to provide ultra-premium tissue products with high bulk, softness and absorbency to a wider range of companies and market segments. The Advantage eTAD technology has proven its capability to produce structured tissue at relatively low operational cost due to its low fiber-, energy and water consumption compared to other structured tissue processes” says Jan Erikson Valmet

“This technology meets consumer needs for premium qualities in tissue products, including softness and absorbency,” says Kurt Adams, Vice President, R&D, Georgia-Pacific. “We are pleased to make eTAD™ technology available more broadly.”