Increased efficiency for CHP plants and paper mills

Process efficiency can be significantly increased by utilizing flue gas condensing to recover heat: a source of energy that typically goes up in smoke.

Flue gases contain plenty of (mainly latent) heat, especially when the fuel’s moisture content is high. After combustion, the moisture from the fuel is in vapor form in the flue gas, with high enthalpy (kJ/kg). In a normal combustion process, this energy is not utilized, and all of it literally goes up in smoke.

Typically, CHP plant efficiency has been close to 90 percent. Overall power plant efficiency is calculated using the lower heating value of the fuel – the energy lost in flue gas moisture is not taken into consideration. Although a little deceptive – the fuel moisture has a very significant effect – this efficiency calculation method has become the norm in the energy industry.

Almost all the energy from the flue gas is released when the water vapor condenses into liquid form. Condensation occurs as the flue gas reaches the dew point of water, where the relative humidity is 100%. The higher the moisture content (the higher the dew point) and the lower the district heating water return temperature, the greater the heat recovery. By adding a combustion air humidifier into the mix with the condenser, we can achieve even greater heat recovery. The flue gas temperature leaving the stack may even be reduced to 35 °C, which is roughly 100 °C less than in a conventional process.

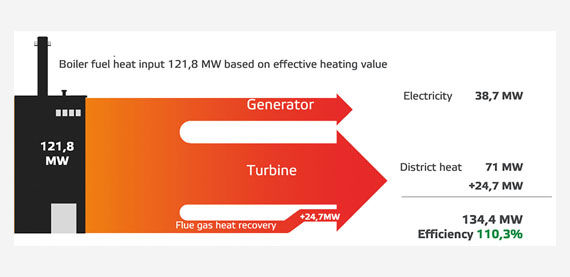

The feasibility of flue gas condensing becomes apparent when the power plant’s total condensing efficiency is calculated. An increase of 24.7 MW in the district heating energy produced increases total efficiency to 110%. This defiance of thermodynamics of course stems from the usage of the lower heating value in the calculation.

Short payback time

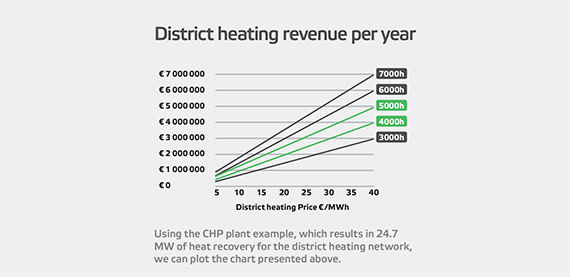

District heating demand fluctuates with the need for heating, i.e. the weather. This means that the maximum potential cannot be utilized all year round. For this reason, the most likely profit lines have been highlighted in green (see chart). However, if the district heating return temperature remains nearly constant throughout the year, it may be possible to operate with the two highest profit lines.

The calculation can be made by using either the cost of fuel (generating savings) or selling price (generating revenues). A conservative estimate of EUR 20 per MWh (low-cost biomass) in district heating savings and 5,000 operating hours suggests we can achieve savings of roughly EUR 2.5 million per year, meaning a typical payback time of less than two years.

Flue gas condensing can be used to increase the efficiency of various processes in which it is possible to utilize low temperatures.

Recovered heat to replace steam consumption

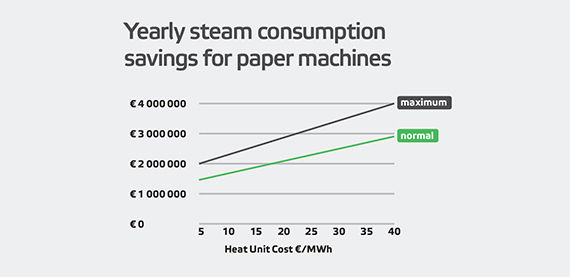

Flue gas condensing can be used to increase the efficiency of various processes in which it is possible to utilize low temperatures. Potential heat sources are fresh and white-water heating in paper machines, and heating of boiler water and turbine condensate.

The concept diagram presents a situation where heat recovery for district heating is unavailable, but the condenser can recover heat for paper machines, where it can replace the steam consumption used for heating, generating savings. With 8,000 operating hours and fuel savings of EUR 20 per MWh, the payback time for the condenser becomes very attractive, with yearly savings of between EUR 1.5 million and EUR 2.0 million.

Heat recovery by flue gas condensing

The power plant heat balance and efficiency illustration highlights the potential for recovering heat by flue gas condensing.

Case example: boiler fuel heat input is 121.8 MW based on effective heating value.

TEXT: Lari-Matti Kuvaja

Article published in Forward magazine 1/2019.