Significant CO₂ emission reductions through paper making technology development

Valmet’s key objective is to enhance the competitiveness of our customers’ processes by improving the productivity and efficiency of their production lines and promoting sustainable paper production through the best available technology and innovative technological solutions. For this goal, we have created our most energy-efficient paper making line.

Valmet smart line is a simulated energy-efficient paper and board production line, representing the best available technology from Valmet where everything is designed with sustainability and cost-competitiveness in mind. It includes the latest technology, and it saves a significant amount of CO2 emissions when compared to more traditional machines.

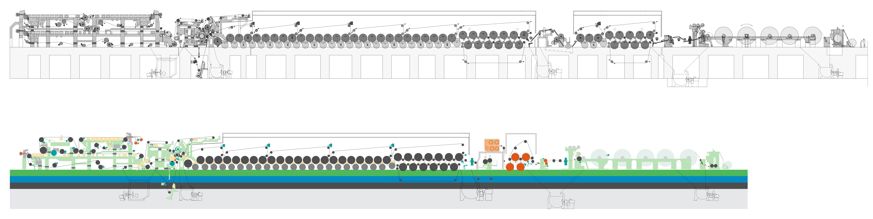

The first Valmet smart line simulation was made for containerboard. It is an updated and improved version of a Valmet-supplied machine that represents more traditional technology. It has a similar production and product quality to the original board line. Also, the investment costs of the machine are approximately the same. Valmet smart line for containerboard is 28 meters shorter compared to the original one and significantly saves machine hall space and costs.

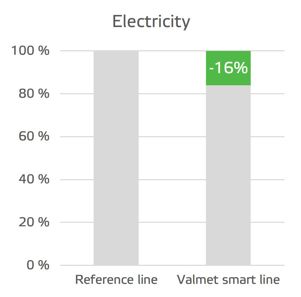

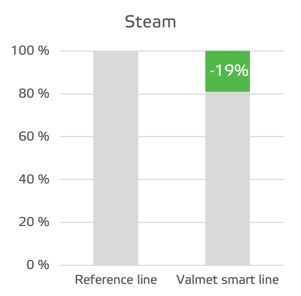

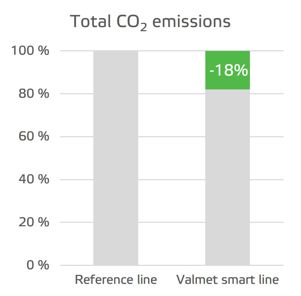

Energy efficiency has been in our R&D’s focus for a long time and the development has borne fruit. Valmet smart line saves 16 percent of electricity and 19 percent of steam as consumption decreases when compared to the original line. Energy efficiency is enhanced with many Valmet solutions. For example, savings from stock preparation come from a newly developed static mixer, combined save-all and broke thickener as well as Twister Hydrocyclone which has the same cleaning efficiency at twice the consistency. On the paper machine, novel Sleeve roll technology has a very high dewatering pressure compared to traditional technologies which enables a shorter forming section. This helps to reduce the electricity consumption of drives and vacuum systems in the forming section while increasing capacity. Heat recovery is optimized with OptiAir Recovery by replacing primary energy with recovered heat from the process. Steam consumption is reduced with several solutions, one of which is OptiSizer Hard which enables the usage of increased starch concentration which reduces the need for after-drying.

All in all, Valmet smart line for containerboard saves an estimated 18 percent of carbon dioxide emissions compared to the reference line.