Online fibrillation measurement: a breakthrough in real-time sheet strength management

Papermakers have known for decades that sheet strength properties are related to refining energy, however stable freeness has been the primary objective for

adjusting refining energy. It is true that freeness measurement is influenced by

the degree of fiber fibrillation created in the refiners, however the main goal

of freeness control is to produce a furnish that drains consistently and runs

well on the paper machine. A more direct way of managing sheet strength based on proven fiber bonding science is called for. On the other hand, fiber physicists have known for many years that fiber fibrillation created in LC refining is the key factor in creating high bond strength between fibers and a strong sheet of paper. The fiber physicists have used laboratory microscopy to identify this fine detail of fibers and how it is related to refining and final sheet

properties. But those microscopy studies do not reflect the real-time

variability of sheet strength in a papermaking process.

The fiber-bonding theories are well established, but the translation to real time papermaking control has not been available until recently. Now, with online high definition imaging in Valmet’s Pulp Analyzer, it has been proven that these microscopic measurements can be used to predict sheet strength and other properties. This opens the door to real-time control of sheet strength and perhaps a different way- or even a paradigm shift- in the way refiners are controlled. This is welcome news to papermakers who are trying to make a uniformly strong sheet with lower basis weights, higher ash levels and less desirable and non-uniform recycled fiber in the furnish.

Valmet Pulp Analyzer (Valmet MAP)

How does fibrillation affect sheet strength? External fibrillation can be defined as a peeling off of fibrils from the fiber surface, while leaving them attached to the fiber. Small objects outside the region containing fibers are not calculated in the fibrillation index, but instead as fines of differing dimensions. As expected, fibrillation is improved with increased refining energy. The external fibrillation of the fibers contribute to paper strength the same way the small wires that interlock the rebar in concrete, whereas the long fibers may be compared with a function of the rebar itself. This fibrillation increases the bonding surface area of fibers ensuring the fiber to fiber interlocking required to improve paper strength properties.

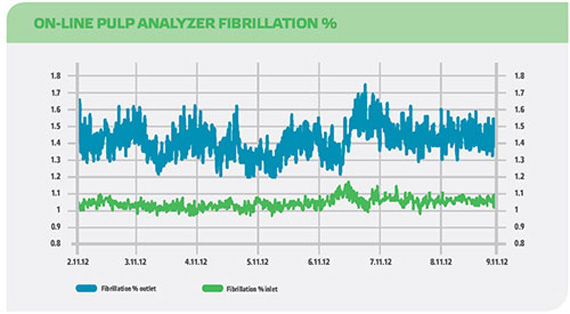

The fibrillation of fibers is measured in the Valmet Pulp Analyzer by a high definition image analyzer that is an upgrade to previous generations of fiber analysis modules in Kajaani MAP and Metso MAP analyzers. The image analysis processing determines the degree of fibrillation. The analyzer also measures many other fiber properties including fiber length distribution and fractions, fiber width, kink, curl, coarseness, vessel cells and shives. The analyzer also includes a freeness measurement module. The fiber samples are taken by process sampling devices at up to 20 points. The measurement cycle time is 3 to 6 minutes depending on the configuration.

Soft-sensor predicts strength

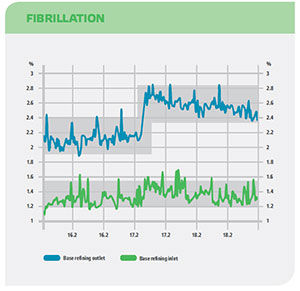

The online measurement has been shown to respond to changes in refining conditions and to show trends and significant variability in fibrillation that would translate to changes in sheet strength. This variability can come from normal refining condition changes including refiner plate wear, consistency variations and chemical factors like pH.

|

Fiber fibrillation is manipulated by refining using the online measurement. |

In a 2-stage SWK refining system variations in fibrillation over seven days are

40%.

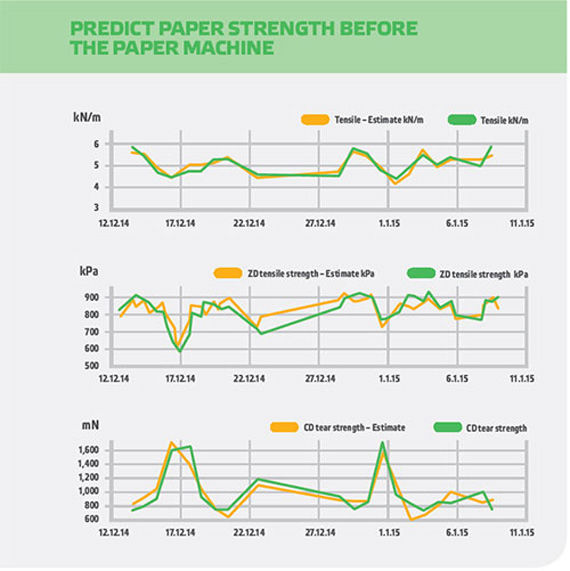

Once the validity of the measurement was established, the next step was to use

the fibrillation data to see if final sheet strength properties could be

predicted with certainty. Measurements from the Fiber Imaging Module are

processed by a partial least squares (PLS) regression algorithm method which is

used to develop a modeling tool for paper strength properties based on the

analyzer fibrillation and other online fiber measurements. The models which have been created using the modeling tool are transferred to the Valmet Softsensor predictor. Additionally, the modeling method can be used to predict pulp strength properties. The program is stand-alone and can be automatically

maintained in a process control system.

It has been observed that fibrillation is heavily weighted in all strength prediction models that have been tested. Freeness and other fiber properties still play an important role in strength prediction, but fibrillation has significantly improved the model stability.

The online measurements have been used to successfully predict

sheet strength properties that compare very well to laboratory tests. This

includes tensile, z-direction tensile, and CD tear. The elongation test in

tissue has also been modeled. Fiber properties also influence other paper sheet

properties. For instance, it has been shown that there is a strong correlation

to formation index.

Better furnish control: cost-effective papermaking

Online trending of sheet strength properties derived from fiber fibrillation, refining energy and freeness reveal that the consistency of end product strength is heavily dependent on fibrillation. Freeness alone is not sufficient to achieve stability, although it is a constraining variable. Papermakers have always relied on freeness, but have long suspected it didn’t tell them everything. It turns out they have been right all along. That missing on-line information is now available and will no doubt change the way refining is managed in stock preparation. For stable strength control a multi-variable model is called for. That process is currently underway at mill sites.

Conventional control using freeness to control specific energy may have to be updated with new and more effective models based on fibrillation. Fibrillation control represents a step above traditional horsepower days per tonne and freeness control since it can make online compensation for consistency, plate wear and changes in stock chemistry to produce a paper sheet that has consistent strength. With that consistent strength achieved by the fibers, papermakers can run lower basis weights, higher ash contents and can tolerate lower-quality recycled furnish with the optimum fiber blend consuming the right amount of energy. With more cost-effective furnish, a significant return on investment is possible.