Why should I choose a pinch valve for a slurry control application?

Slurry flow control expert Juha Häkkinen, a Senior Manager, OEMs, was asked to answer this commonly raised question.

There are three main advantages to choosing a pinch valve for slurry control application: first, the abrasion resistance; second, wide flow control range; and third, the low life cycle cost.

1. Best available abrasion resistance

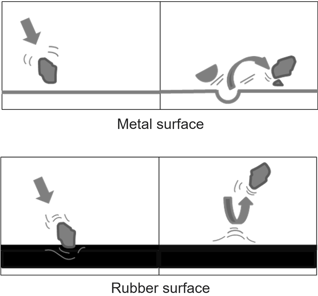

The main reason is the resistance to abrasion. Slurries are typically very abrasive, the kind of texture for which rubber is the best solution, and in a pinch valve, the rubber sleeve is the only part in contact with the abrasive slurry. When a rubber sleeve is hit by the solid particles, the rubber temporarily deforms rather than degrades. In other terms, rubber absorbs the particle's kinetic energy and then returns it back to the particle. This limits the damage to rubber as compared to metal.

The standard abrasion-resistant SBRT (styrene butadiene) rubber sleeve covers 90% of control pinch valve applications. For special applications and for extreme wear and abrasion, there are special rubber solutions available, namely the polyurethane-lined sleeves and extra soft NR (natural rubber) sleeves with their maximal abrasion resistance.

2. Wide and linear flow control range

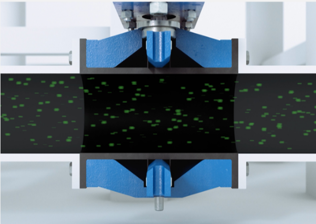

A fully open pinch valve and the sleeve inside the valve body is simply an extension of the pipeline. In practice, this means that the installed control pinch valve has zero flow resistance in a fully open position. This results in the largest flow control range when compared to the other valve types of the same size.

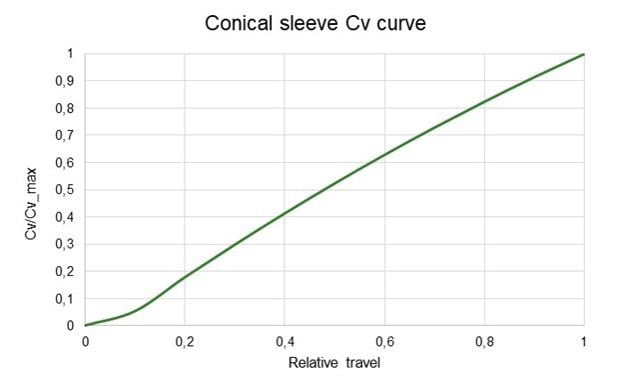

One favorable feature of control pinch valves is their capability to use cone-shaped sleeves to generate a control curve that is almost fully linear.

Improved controllability with a conical sleeve results in a linear control curve.

This further widens the flow control range and nearly the whole relative travel from 0.1 to 0.9 could be taken into use. This is favorable, for example, in flotation level control applications where both the wide flow control range and flow control accuracy are required. The proof of that is the fast-growing installed flotation control pinch valve base by Flowrox™, which had logged over 3000 deliveries by the beginning of 2023.

3. The lowest life cycle cost

Rubber sleeves are available in several sizes and materials.

Another advantage is the low life cycle costs of the pinch valves. All valve types require maintenance, and with pinch valves, that means just changing the rubber sleeve.

The rubber sleeve is a low-cost wear part which can be quickly changed on site without any need for machining, special tooling or required special skills. With less than a half-day’s work, the control pinch valve is back on duty. Also, it is worth mentioning that correctly sized control pinch valve sleeves can last for years, the record being more than two decades.

Juha Häkkinen

Juha Häkkinen

Senior Manager, OEMs and

Slurry Flow Control,

Mining and Metals Industry

Subscribe to our newsletter

Subscribe now to flow control newsletter and receive the latest insights directly to your email.

SubscribeRead more about related products and services