Not only for pulp and paper: Innovative new products based on wood and straw resources

Intense research is going on in many countries to use biomass more effectively, with terms such as bioeconomy and biorefinery becoming more well known every day. One example is to use the biobased chemicals derived from wood- or agro-residuals as the basic raw chemicals for the chemical industry, replacing fossile-based feed stock chemicals.

BioTrac pilot plant in Sundsvall, Sweden.

A wide variety of different types of biomass can be used as the input feed, including: forest residues or saw dust from wood, straw, cornstalks, miscanthus grass, sugarcane (bagasse) and even residues from palm oil processing fr. Of course, it is possible to cook those materials in an alkali solution to produce fibers for the paper industry, but todays’ ambitious targets are aiming much higher, at more sophisticated end products.

Many highly innovative companies in Scandinavia and Finland are today working with very interesting concepts based on wood and other lignocellulosics.

One example is the production of bioethanol, i.e. as an drop-in fuel or as a base product for more complex chemical substances. First generation bioethanol was produced directly from grain. At the end of the 1990s a discussion started: “plate or tank?”, meaning should these grains go into food or fuel. The winner was “plate” and today the second generation of bioethanol is on the way.

The starting products can be different types of straw, wheat straw, rice straw or even lavender straw. An important role falls on enzymes, which prepare the straw for the necessary fermentation and subsequent distillation. Wise old nature has been careful not to allow the enzymes already in the fields to attack the wheat plant structures. To produce straw bioethanol, therefore, the straw must be prepared in such a way that the enzymes can start their activity.

A good way to do this is via steam explosion treatment. The simple batchwise steam explosion (or Masonite process, patented by William H. Mason) was developed 100 years ago and was widely used to produce wet hardboard panels for the furniture industry.

In 2008 Valmet looked into Mr. Mason’s idea and developed a continuous thermal pre-treatment system called BioTracTM. The BioTracTM system has since then been scaled up from pilot to demo and through to commercial scale.

This advance opened the way for the enzymes to work more efficiently on straw or other annual plants. In 2015 Valmet's first pilot was started in Sundsvall and since then conducted hundreds of trials for different feedstocks optimizing the pretreatment process for the purpose of making second generation bioethanol.

On a commercial scale the polish based oil industry corporation Orlen is building their first second generation bioethanol plant based on Valmets Biotrac pretreatment system, the plant is planned to start up in 2025.

Valmet’s BioTracTM system to treat straw, wood and other plants is now in operation at capacity of more than 30 dry tons per hour. The main control parameters are retention time and a wide spectrum of steam pressure levels. Many new business areas that are making use of this technology are popping up all the time.

For example, steam treated pellets, using both hardwood and softwood and even bark, are transformed into hydrophobic, dark industrial pellets with high energy density. There is a high level of interest worldwide in this new product and the first plant is producing approximately 15 t/h of pellets.

Of high interest as well are the liquid chemical byproducts which are created during the steam treatment process. Another highly demanding job that may possibly be tackled with this steam treatment process is the recycling of valuable fibers from post-consumer furniture and laminate flooring.

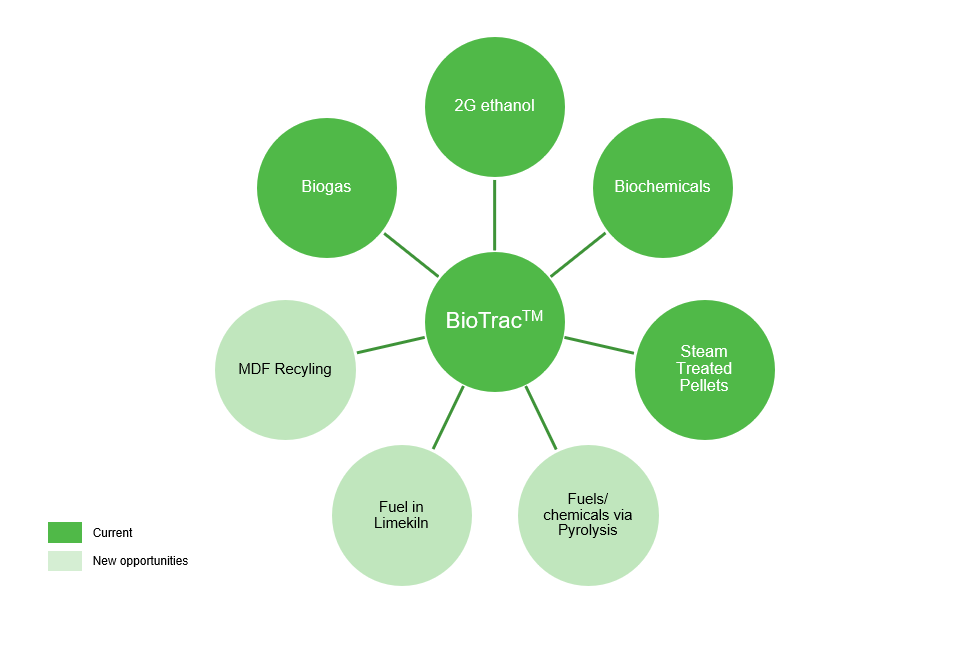

Figure 1: Applications, current and under evaluation BioTrac platform.

To push these developments forward, in 2021 Valmet rebuilt and expanded the existing BioTracTM pilot plant in Sundsvall, Sweden. Customers from all over the world have already used the high-tech equipment and have booked tests with their specific raw materials. The continuous working plant can process up to about 200 kg wood per hour.

Depending on the final product desired, a chemical pre-impregnation or even a dryer is available. The machines are designed for the use of all types of wood and lignocellulosic annual plants. The experienced research team at Valmet Sundsvall is fully convinced that many more CO² neutral products based on lignocellulosic raw materials will have their birthplace here.

Related content

Our expertise is at your service

Our focus is to bring your performance forward. Get in touch with us through our website, or through your local Valmet office.

Contact us