Something old, something new

The BillerudKorsnäs Karlsborg mill, an integrated pulp and paper mill in northeast Sweden, manufactures world-leading sack and kraft paper and 170,000 tpy of bleached softwood market pulp. The mill has a long history with Valmet going back to 1980, when a Valmet Damatic distributed control system (DCS) started up at the mill. In October 2017, the key personnel of the mill was in Tampere to attend the factory acceptance test of their first Valmet IQ quality control system (QCS) for the mill’s pulp drying line.

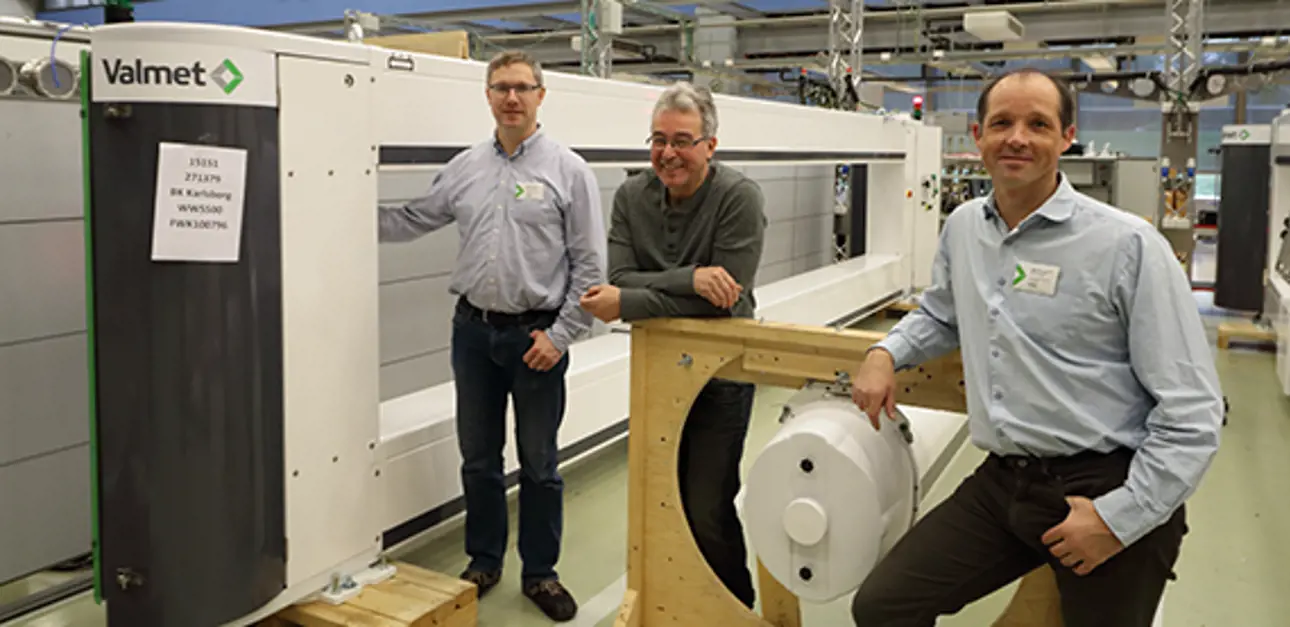

Main image: In Valmet’s QCS testing area Mattias Arvidsson, Nils-Olov Ekholm and Bjarn-Olof Johansson together with the Valmet IQ scanner before its delivery to the Karlsborg mill.

Machine and automation expertise

As well as meeting the performance requirements of the mill, the decision to buy the Valmet IQ quality control system rested on Valmet’s unique combination of machine and automation know-how. According to Mattias Arvidsson, Project Manager at the mill, “We started looking at four automation suppliers in the initial stage, but the ability of Valmet to deliver not only the QCS but also to take care of the necessary machine alterations to accommodate the scanner had obvious advantages. This Valmet turn-key concept meant we would not have to take care of the engineering and supervision of the machine rebuild, Valmet certainly knew better than we did of what was needed.”

Relocation of the pull nip involved modifications to the machine frame and platforms as well as moving the pull nip and drive. This was done by Valmet together with a new broke pulp chute during the scheduled five day maintenance shut in August. “It saved us a lot of man hours and with Valmet’s proven machine expertise we have the guarantee that installation of the scanner later in October will be straightforward and problem free,” says Arvidsson.

Damatic Classic, still going strong after more than 30 years

Another member of the Karlsborg team in Tampere for the factory acceptance test was Nils-Olov Ekholm, Mill Process Engineer. He joined the mill when the first Damatic DCS in the mill was less than a year old. Now known as Damatic Classic, he remembers it was very advanced for time, “The fiberline Damatic was already up and running, interfacing the instrumentation, pump motors and valves to replace the earlier panel instrumentation. When I joined the company in February 1981 the bark boiler project was just starting up. Over the years Damatic proved to be very reliable,” states Ekholm.

Bjarn-Olof Johansson, Automation Technician, looks after the machine and knows its reliability. The Damatic Classic of mid 80’s vintage still controls the steam and condensate system of the coating machine on BM1. “It is more than 30 years old but still in operation,” he says.

Joining the company fresh out of college in 1988 his first impression of Damatic was positive. “The programming language was very similar to what I had learned in school, it was very impressive that this could control the complete process.” Johansson still fondly remembers his first training session in Tampere in 1990, and today his responsibilities cover Valmet’s automation in the mill from that early Damatic Classic up to the most recently installed Valmet DNA system.

Valmet IQ - the latest technology

The QCS delivery to the BillerudKorsnäs Karlsborg mill represents Valmet’s latest technology of traversing scanner with basis weight and moisture sensors accompanied by a Valmet IQ One-sided Scanner measuring moisture and temperature across the machine after the press section. Machine direction controls for moisture and basis weight as well as coordinated speed control are included. The factory acceptance test enables the mill personnel to test the functionality of the complete system including measurements, controls and operator displays prior to installation. Following the first week of October’s factory acceptance test, delivery of the system was scheduled for October 18th with installation during a short shut of about 20 hours the following week.

The Valmet IQ One-sided Scanner will be installed after the press section on Karlsborg’s pulp drying machine.