Slitter management for improved cutting process at board and paper machines

Superior sharpness and cut quality with Valmet’s top- and bottom slitters

Slitter management at board and paper machines was developed by Valmet to help our customers overcome winder problems such as poor slitting equipment condition, poor quality blades and bands, dull blades and bands, hand injuries and insufficient operator slitting process knowledge and abilities. Valmet Slitter management brings slitting best practices to your winder. Our services and technology include state-of-the-art blade design and materials, sharpness techniques, safe and easy slitter changes, and comprehensive OEM slitter section training.

Improved cut quality

- Eliminate cracks, flaking and fuzzy edges

- Reduce slitter dusting

Increased productivity

- Decrease roll rejects

- Reduce unscheduled downtime

Cost savings

- Increased blade life

- No need for the customer’s own inventory investments

- Improved maintenance efficiency

Proven results

- Improved converting and printability

- Printing houses are satisfied on shipping roll quality

Be smart, stay sharp - Slitter Management Program to secure an effective replacement process and continuous sharpness

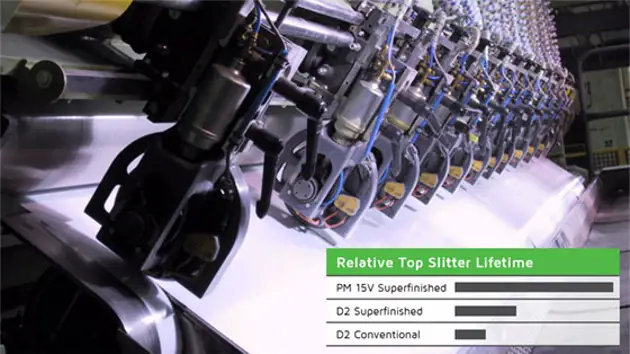

Valmet Slitter Management Program is tailored to your needs. It includes the high-quality top slitters and carbide bottom bands with the hardened outer surface, superfinishing grinding of top and bottom slitters, automatic replacement of top and bottom slitters from a blade pool, slitter blade storage & transport boxes, and transportation to grinding and back. Further, the first installation of slitters is always conducted by our specialists.

The Slitter management program considerably reduces the maintenance costs, extending slitter blade life and blade change intervals, thus improving slitting performance. More effective winder operation improves the productivity of the entire line. With a fixed yearly fee contract, customer can reduce costs and administration with increased cost predictability. It also reduces the customer inventory value and minimizes the yearly transactions from sourcing.

Discover the latest in slitter management – browse through our collection of brochures and flyers

New sustainable blade packaging

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usSafe, fast and easy top slitter change

Changing top slitters is traditionally complicated needing special tools, taking time, and causing hand injuries. Since Valmet Slitter Holder Quick Change was introduced to paper and board mills, our customers witness a safe, fast and easy slitter change:

- Minimum six times quicker slitter change than with the original holder

- No threads, screws or tools required

- Enables change of top slitter without planned shutdowns

- Improved roll and cutting quality

- Less roll rejects, dust and fewer complaints from printing houses

- Top slitter release mechanism operates only when the slitter is not in the slitting position. The function prevents accidental release of the top slitter.

- Braking mechanism in the bearing assembly stops the rotation of the slitter and holds it in place when it is not in the slitting position

Slitter management services

Additionally, needed amount of Valmet Slitter Holder Quick Change can be included to Slitter management agreement fee to avoid investment and to ensure the performance of cutting devices.

We recommend a full mechanical winder audit to be performed annually. The audit helps identify winder issues beyond the slitter section, catching winding process problems before they snowball into larger issues. This service can be included in the slitter management program.

Whether you are operating under a slitter management agreement or not, Valmet can supply exchange units or rebuild your existing equipment. This service is available for all Valmet slitting equipment.

Read more about our offering

Articles and references