Valmet Quality Predictor

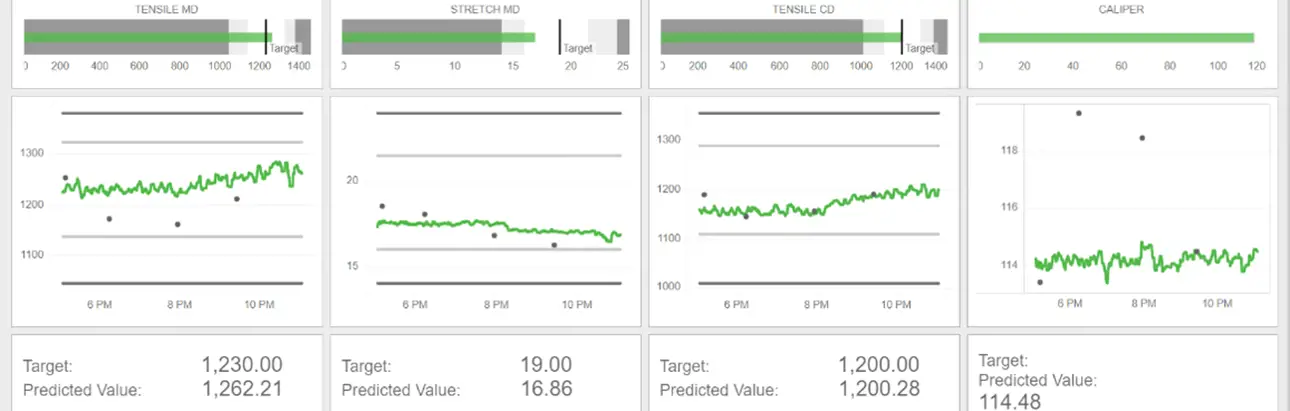

Real-time values for selected quality parameters

Valmet Quality Predictor is an advanced application that shows real-time values for selected quality parameters. This way, it removes the harmful waiting time of laboratory results and enables operators to take action in the early phase and stay within the given quality limits.

Cuts the delay of waiting for the laboratory results

Gives the prediction for full mother roll length

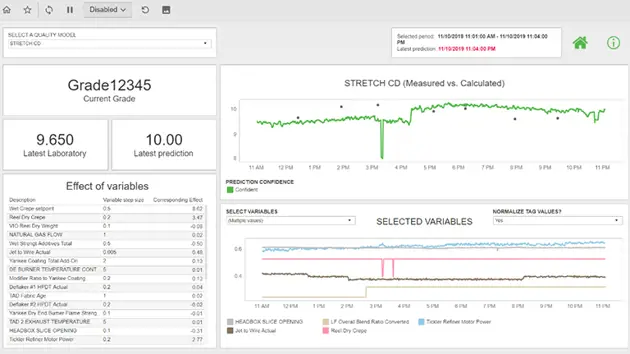

Shows the relations of different setpoints and quality parameters

Helps to avoid quality costs significantly

Valmet has the competence to build accurate predictive models for different quality parameters via the collaboration of data scientists, process technology, and system experts. The most classic quality parameters to be predicted are paper and board strengths (tensile, tear) but the experience of modeling different parameters is diverse. The quality parameter selection for Quality Predictor is always based on the customer's need.

Quality Predictor is most useful for operators whose responsibilities include consistent process quality improvement and optimization. As a benefit, the quality costs are reduced while the stability of the process is easier to maintain, and within quality limits.

A detailed view dives deeper into one selected quality parameter, showing the factors and process variables that affect the prediction.