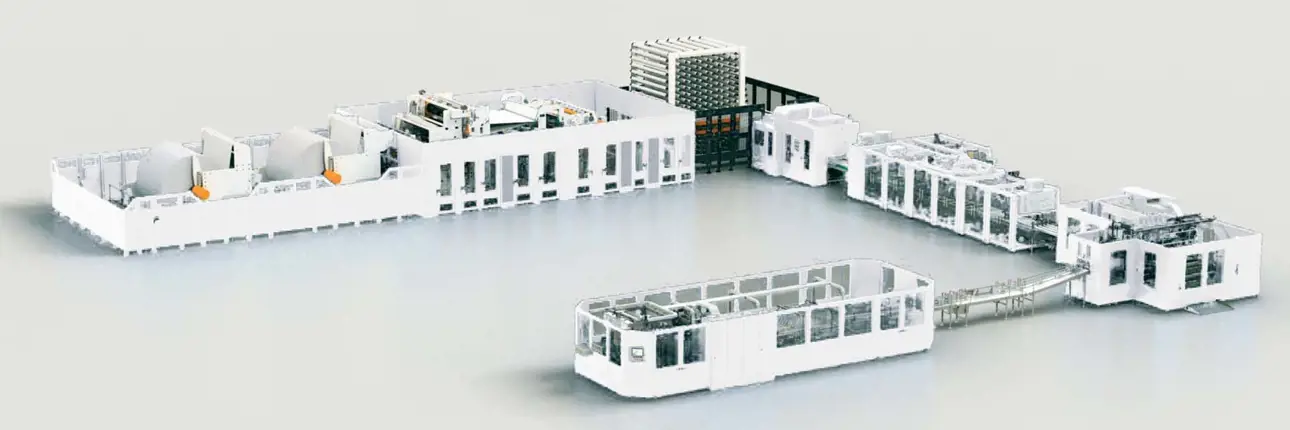

Pre-configured lines - MyPerini

MyPerini Converting lines aligns Total Cost of Ownership (TCO) and best Overall Equipment Effectiveness (OEE) by getting products to market efficiently. Pre-configured and ready to run, these tissue paper packaging machines are world-class performers with streamlined, optimally priced tissue manufacturing process customization.

Quick solutions

- Reduced lead Time

- Faster start-up

- Quicker time-to-market

Optimal solutions

- Balanced configuration

- Easy to use for operators

- Reduced line footprint

Long-lasting solutions

- Proven technology

- Upgrades for longer lifecycle

- All aftermarket services

Perini MyGo

Based on Perini MyLine with evolved Sincro technology, Perini MyGo is a ready for operation line with the most common configurations requested by the market, that enhances the advantages of Perini MyLine optimizes machine installation operations, in favor of drastic reduction in start-up time.

Thanks to an ergonomic design with integrated electrical panels, cable duct and perimetral guards, the individual units that make up the line, can be loaded directly on the truck/container by simply disconnecting the power supply.

Technical characteristics

- Up to 30 log/min

- Max roll Ø 200 mm

- Speed 600 m/min

Perini MySincro

Perini MySincro manufactures toilet and kitchen rolls with diameters up to 160mm at a maximum speed of 450m/min and 30 log/min output. Based on our Sincro exchange phase system, this line is equipped with a laminator-embosser featuring 409mm diameter steel rolls to deliver high quality glued products.

Technical characteristics

- Up to 30 log/min

- Max roll Ø 160 mm

- Speed 450 m/min

Perini MyLine

This line is designed for manufacturing toilet and kitchen rolls with diameters up to 200mm at a maximun speed of 600m/min and an output of 40log/min. Based on our proven Sincro exchange phase system, the Perini MyLine line is equipped with a laminator-embosser featuring 409mm diameter steel rolls with DESL or Catalyst technologies for the automatic changeover of the steel rolls, respectively in the Pro and Flexy versions.

Technical characteristics

- Up to 40 log/min

- Max roll Ø 200 mm

- Speed 600 m/min

Perini MyTime

This line is designed for manufacturing toilet and kitchen rolls with diameters up to 200mm at a maximun speed of 800m/min and an output of 60log/min. Based on the innovative low-energy, low-noise Sincro-Evo exchange phase system, the Perini MyTime line features also the peripherical-central hybrid winding system with Punzoncini technology, which makes it ideal for manufacturing soft, bulky products at high speeds

Technical characteristics

- Up to 60 log/min

- Max roll Ø 200 mm

- Speed 800 m/min

Perini MyGo

Based on Perini MyLine with evolved Sincro technology, Perini MyGo is a ready for operation line with the most common configurations requested by the market, that enhances the advantages of Perini MyLine optimizes machine installation operations, in favor of drastic reduction in start-up time.

Thanks to an ergonomic design with integrated electrical panels, cable duct and perimetral guards, the individual units that make up the line, can be loaded directly on the truck/container by simply disconnecting the power supply.

Technical characteristics

- Up to 30 log/min

- Max roll Ø 200 mm

- Speed 600 m/min

Perini MySincro

Perini MySincro manufactures toilet and kitchen rolls with diameters up to 160mm at a maximum speed of 450m/min and 30 log/min output. Based on our Sincro exchange phase system, this line is equipped with a laminator-embosser featuring 409mm diameter steel rolls to deliver high quality glued products.

Technical characteristics

- Up to 30 log/min

- Max roll Ø 160 mm

- Speed 450 m/min

Perini MyLine

This line is designed for manufacturing toilet and kitchen rolls with diameters up to 200mm at a maximun speed of 600m/min and an output of 40log/min. Based on our proven Sincro exchange phase system, the Perini MyLine line is equipped with a laminator-embosser featuring 409mm diameter steel rolls with DESL or Catalyst technologies for the automatic changeover of the steel rolls, respectively in the Pro and Flexy versions.

Technical characteristics

- Up to 40 log/min

- Max roll Ø 200 mm

- Speed 600 m/min

Perini MyTime

This line is designed for manufacturing toilet and kitchen rolls with diameters up to 200mm at a maximun speed of 800m/min and an output of 60log/min. Based on the innovative low-energy, low-noise Sincro-Evo exchange phase system, the Perini MyTime line features also the peripherical-central hybrid winding system with Punzoncini technology, which makes it ideal for manufacturing soft, bulky products at high speeds

Technical characteristics

- Up to 60 log/min

- Max roll Ø 200 mm

- Speed 800 m/min

Related pages