Low consistency refiners

Refining that delivers consistent quality and cost efficiency

The Valmet Conical Refiner Conflo is designed for low consistency refining across mechanical, chemical, and recycled fiber applications. With precise gap control and optimized flow dynamics, it ensures stable operation, uniform fiber treatment, and improved paper quality—while reducing energy consumption and operating costs.

How the refiner works in your process

The refining process in the Valmet Conical Refiner Conflo takes place between specially tailored fillings, where precise gap control ensures consistent fiber treatment. Its cantilevered design—with a fixed stator and a uniformly moving rotor—maintains a stable clearance, which is essential for uniform refining results. Centrifugal force enhances fiber coverage across the bars, while the extended refining zone increases retention time, allowing for optimized fiber bonding and flexibility. This results in pulp that supports high-quality paper production with improved runnability and fewer web breaks.

What makes the RF-5 model technically outstanding?

The RF-5 is the largest model in the Conflo series, designed for high-capacity low consistency refining. It operates within a consistency range of 2–6% and supports motor powers up to 3000 kW, with a speed range of 330–450 rpm. Its robust design ensures stable operation even under demanding conditions, while the wide selection of filling patterns allows customization. The RF-5 integrates seamlessly with modern automation systems, offering flexible control and easy maintenance – making it ideal for large-scale pulp and paper operations.

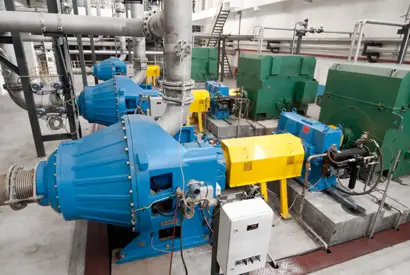

Valmet Conical Refiner Conflo RF-5

Maximum capacity meets precision refining

The RF-5 model of the Valmet Conical Refiner Conflo is built for high-capacity low consistency refining, combining robust motor power with precise gap control. Designed for demanding pulp applications, it delivers optimized fiber treatment, stable operation, and energy-efficient performance – ideal for large-scale production environments.

- High-capacity performance for large-scale refining needs (up to 800 tpd)

- Optimized fiber bonding and flexibility for superior paper strength and bulk

- Energy-efficient operation with low total energy consumption

- Ideal for CTMP production, enhancing fiber properties with reduced energy input

- Quick and easy maintenance with fast filling changes and reliable automation

Material available for download |

||

|---|---|---|

| Conical Refiner Conflo | ||

Interested in mechanical pulping? Let's connect!

Whether you're exploring new technologies or improving existing lines, our experts are ready to connect. Share your needs and we'll help you bring your performance forward.

Contact us