New technology for PressJade coatings

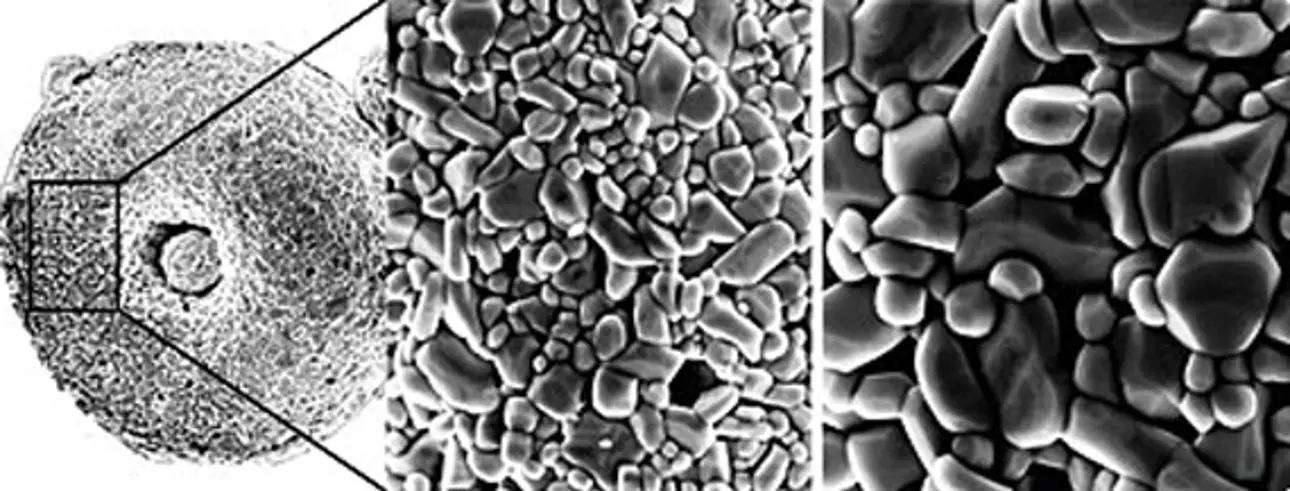

Scanning electron microscope image of the ceramic nanocomposite raw material.

Valmet’s (*Metso (Paper) until Dec. 31, 2013) press section coating family, PressJade, consists of PressJade D, PressJade W and PressJade F ceramic coatings that are engineered for specific paper and board grades. The novel nanomaterials technology behind the PressJade family improves the long-term runnability of center rolls and cuts maintenance costs because of improved stable surface roughness and reduced wear.

Grade-specific composition for optimal runnability

Center roll runnability depends on numerous factors. In terms of the ceramic coating alone, surface topography and such physical properties as surface energy and surface charge play an important role in center roll performance. The surface topography of the roll coating strongly affects the thickness of the water film between the web and coating, and thereby the force needed for sheet release. On the other hand, the physical properties of coating materials have a direct effect on the behavior of water on the coated surface (hydrophilic/hydrophobic) as well as its tendency to attract or repel stickies, binders, pigments and other impurities. This fundamental understanding was utilized already in the development of Valmet’s previous generation of center roll coatings (PressJade, PressGem W, PressGem F) in customizing their chemical composition for different paper and board grades. Now these materials technology lets us go even further.

New technology means longer regrinding intervals

The most important feature of the PressJade coatings is their controlled microporosity. It directly reduces draw (enhanced breaking of the water film) and also keeps the surface roughness of rolls stable even over long periods of service. In practice this means longer regrinding intervals. The nanomaterial composition of the coating has boosted hardness and wear resistance by roughly 20% and impact resistance has also increased. The new coatings have therefore clearly better mechanical resistance against belt and felt incidents than earlier. Their special microstructure makes the coating material hydrophilic and anionic, contributing to a clean roll surface and easy doctoring. Practically no release chemicals are needed with the PressJade coatings.

The new coating raw material is a special ceramic-ceramic nanocomposite. The chemical composition and phase structure of the raw material and its microporosity are based on a very precise formulation. This has led to a unique combination of coating properties that could not be achieved with traditional materials technology.

Now available globally

User feedback on the new coatings has been very positive. The frequent surface reconditioning (on-site superfinishing) of older coatings was eliminated and productivity was improved in two newsprint line cases. The runnability and doctoring of the center roll were clearly improved on a fine paper line, leading ultimately to a new production record.