Carbon capture – Taking the first big steps in the green transition

For many established industries such as coal-fired power plants, refineries, and petrochemical plants, CCUS technologies present an easier way to decarbonize production compared to switching to renewables and adopting new technologies such as electrolysis.

Emissions-free energy solutions

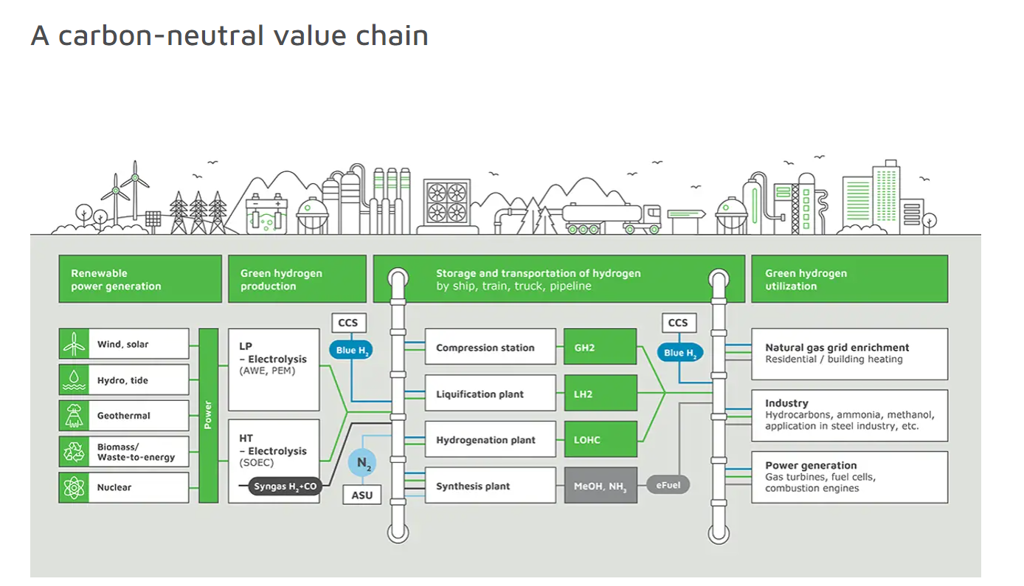

When we talk about decarbonization, we see many industries either apply CO2-removal technologies, preventing it from entering the atmosphere or replacing fossil-based energy production with renewables. Both ways provide the possibility to produce hydrogen, which is seen as one of the keys to more sustainable energy production and use. If the hydrogen is produced from fossils applying CCUS technology, it is called blue hydrogen. It doesn’t matter if carbon capture is done by absorption, adsorption or cryogenic separation, respectively applied either before combustion or after. Our valves are present in most applied carbon capture technologies as well as in the purification and further utilisation of carbon dioxide and blue hydrogen.

New uses for captured carbon dioxide

Of course, what happens to the captured Carbon Dioxide is an interesting part of the equation as well. It is either stored away forever, or more recently utilized in other new industrial applications. It seems that there may be new uses and commercially viable markets for the most vilified emissions in recent history. Captured CO2 is being utilized in new E-fuels as well as in food & beverage and chemical industry applications as a feedstock. For a valve manufacturer with strong experience and knowhow with CO2 applications, this presents interesting new opportunities.

Application understanding and experience

Carbon dioxide in itself is quite a simple gas, but handling it as a flow media is not without its risks. There are risks involved with icing at lower temperatures as well as to do with phasing between liquid and supercritical form. CO2 is typically liquified for transport purposes. Valmet’s flow control business has decades of experience and a proven portfolio of valve solutions for all of the typical CO2 applications from valves for absorption and adsorption to cryogenic valves and capabilities for cryogenic separation where carbon dioxide is handled in liquid form.

Delivering proven performance and reliability

As a leading valve supplier in industrial gas, we are able to promise and deliver on the critical need for long-lasting reliability and performance. Having worked closely with major players in industrial gas, petrochemicals, chemicals we are able to offer our historical knowledge and accumulated skills as a part of our service to all our customers. Deep application and process knowhow is also automatically incorporated into the valve products we deliver.

Sustainable mindset is contagious

The green transition and heightened interest in sustainability and environmental performance in general will continue to serve humanity well in coming years. We are seeing new, exciting applications where carbon capture plays an important role. Industries such as the concrete and cement industries are starting to absorb CO2 from their plants and biomass and waste-to-energy powerplants are popping up in conjunction with carbon capture units.

All these new processes when executed responsibly using reliable and proven technologies from recognized vendors hold the keys to the first successful steps in decarbonizing industry and paving the way for the green transition for real.

Text by Andreas Pischke, Global industry manager, Valmet Flow control business line

Discover more on the topic