Valmet services optimize screening: baskets, recoating and more

Valmet offers customized solutions to improve the reliability and performance of your screening process. We ensure the competitiveness of your screening system by reducing screening costs per tonne produced through cost savings (in materials, energy and maintenance) and by improving screening efficiency. Well-screened stock means better runnability of the paper machine and improved end-product quality.

Depending on your needs, screening improvement may involve a combination of know-how, services and products from Valmet’s service, improvement and upgrade offerings.

The improvement process starts with an analysis of the present condition of the screening process and identification of possible problem areas. This analysis draws on Valmet's process and machinery know-how and analytical services. Valmet then formulates an optimal solution based on the analysis findings and screening targets set with the customer.

From refiner segments and screen baskets to grinding surfaces, Valmet con provide long consumable lifetimes at the lowest total cost. Our consumable agreements are tailored for each production line.

Valmet offers unique, state-of-the-art process solutions for all screen applications. By choosing Valmet as your screening technology supplier, you will receive the benefits of Valmet's in-depth knowledge of the industry, as your partner in optimizing your fiber and paper lines.

Benefits of optimizing a screening process include:

- Maximum process performance

- Better process availability

- Lower screening costs per ton

- Stable end-product quality

Valmet manufactures high-quality screen baskets for most screen makes and models to fit all process positions. Through continuous coating development, we can also provide special coatings that guarantee the longest lifetime of screen baskets on the market.

Chemical pulping

Valmet Screen Basket H1

Valmet Screen Basket NC

Mechanical pulping

Valmet Screen Basket H2

In addition to better capacity, Screen basket H2 helps keep screens clean. The special electron-beam drilling method makes the perforations ideally conical, so they remain clean and open. The Screen Basket H2 is designed for use in fiber recovery and water cleaning applications.

Valmet Screen Dilution Belt

A Canadian TMP mill has reported excellent results after the installation of its first Screen Dilution Belt basket. In spite of wider slots in both the primary and the secondary stage, the Screen Dilution Belt basket has proved superior to the reference basket. A Swedish market pulp mill produces groundwood pulp from spruce and aspen. The use of Screen Dilution Belt brought shive removal efficiency to levels that were previously unobtainable at the mill. By adding the correct amount of dilution water in the correct position, a lower rotor speed could be used. Energy was saved and screen basket service lifetime increased due to reduced wear.

Chemical & mechanical pulping

Valmet Screen Basket NL

Highly accurate narrow slots with Screen Basket LD wire profiles create an optimized flow pattern to deliver controlled thickening and low reject rate, together with minimal debris, sticky and contaminant breakdown providing additional savings through lower usable fiber loss. Wedge wires feature Valmet Screen Coating L for high wear applications giving basket performance and lifetime comparable to baskets costing up to 25% more. Low flow resistance combined with the large open area of the screen provides high screening capacity with efficiency. With Valmet Screen Basket NL you will be able to target pulp quality and boost efficiency in a wider operating window.

Valmet Screen Recoating Services

Valmet has developed a proactive recoating service to optimize screening performance. This innovative service ensures that the screen basket profile is maintained in top shape at all times by replacing the baskets before their profile starts to wear down and then recoating them. Knowing when to replace and recoat the baskets is the key to minimizing unplanned shutdowns, ensuring stable performance and saving costs.

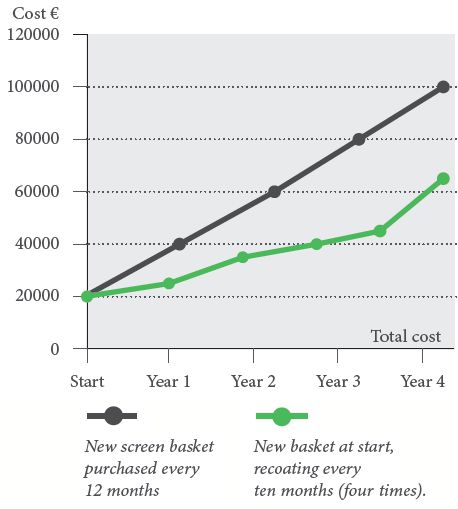

Cost comparison - new baskets vs. recoating

Recoating services are a cost-effective solution to maintain capacity at a desired level. Recoating, instead of buying a completely new basket, brings considerable savings in screening costs. This is illustrated in the graph showing a cost comparison in a typical case.

StockBoost for optimal performance

For more information on lowering your total screening costs for your fiber, paper, board or tissue line, contact your Valmet representative.