Appendices

A Sizing examples

The sizing examples presented here are based on sizing coefficients of Valmet's control valves. The sizing coefficients can be found from Valmet's sizing coefficient tables.

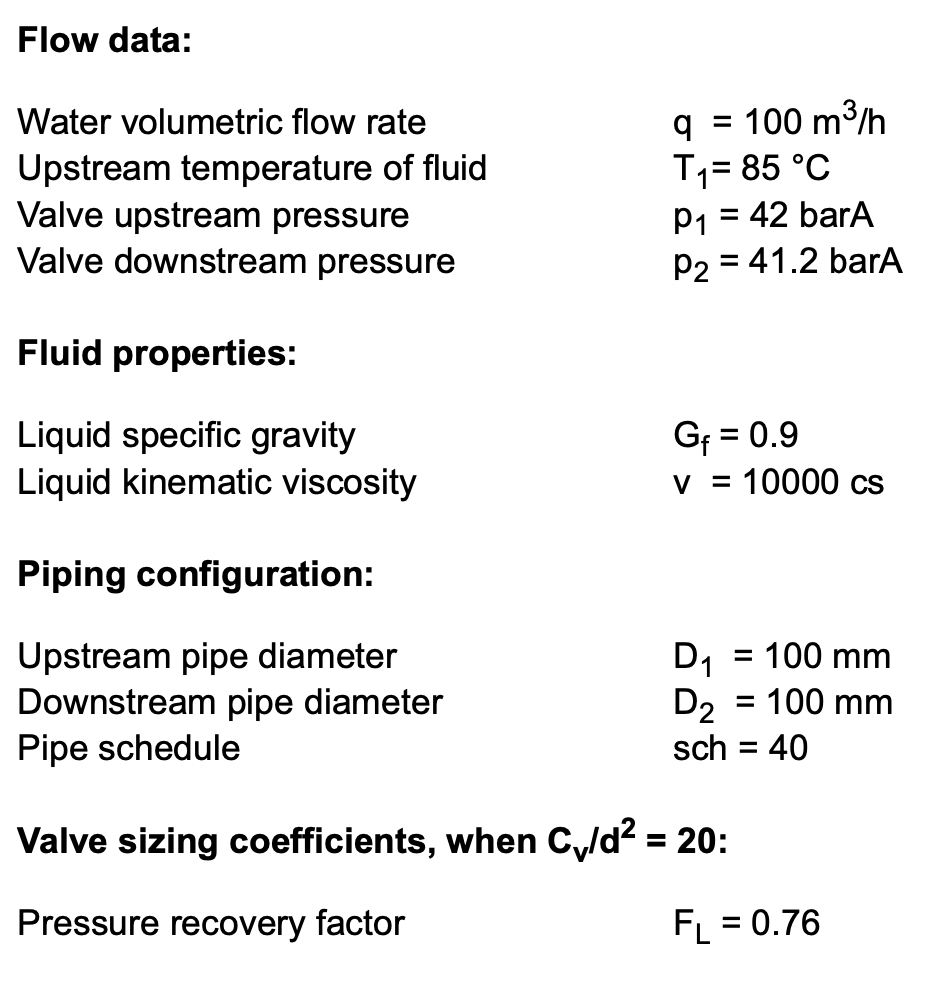

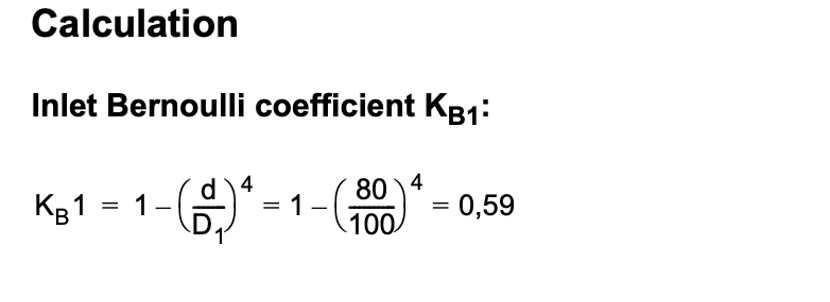

Liquid flow sizing example

D series ball valve is controlling high pressure viscous oil flow. Valve size is 100 mm. What is required capacity Cv and opening of the valve with given flow data?

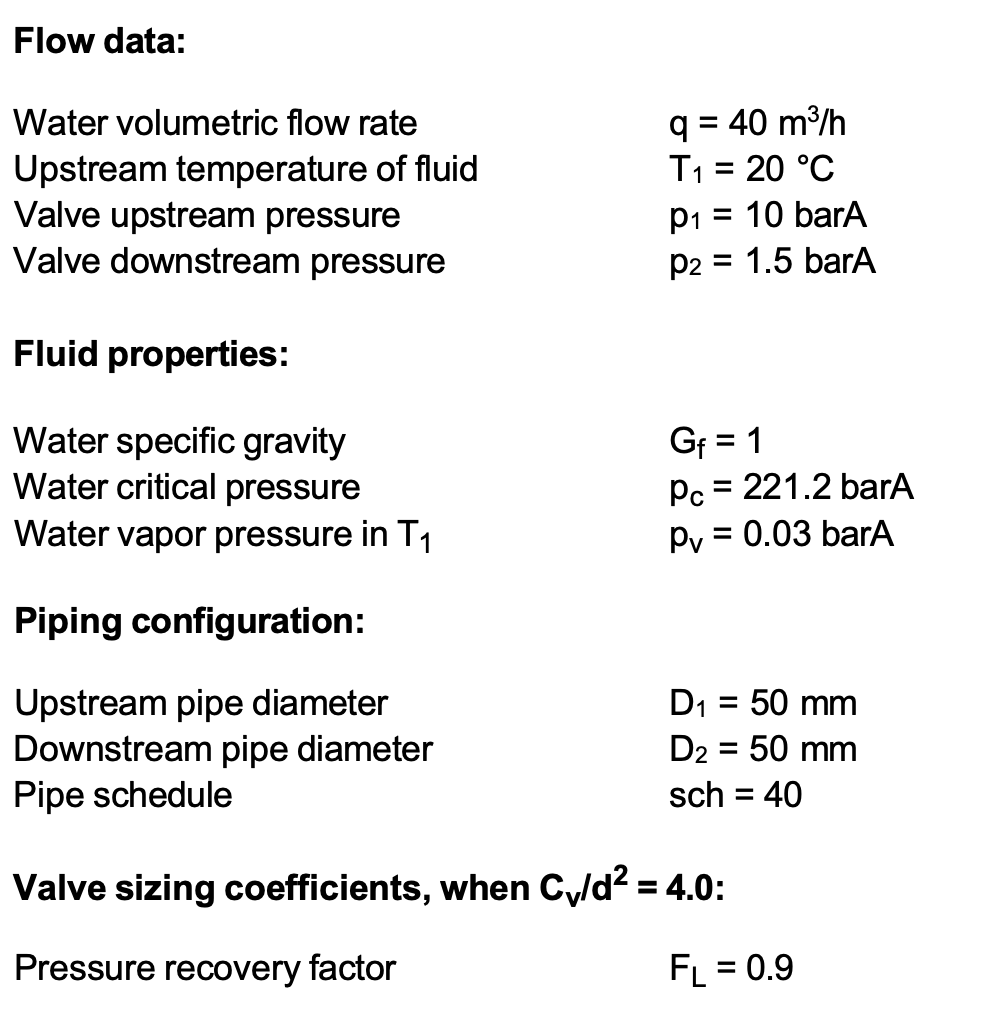

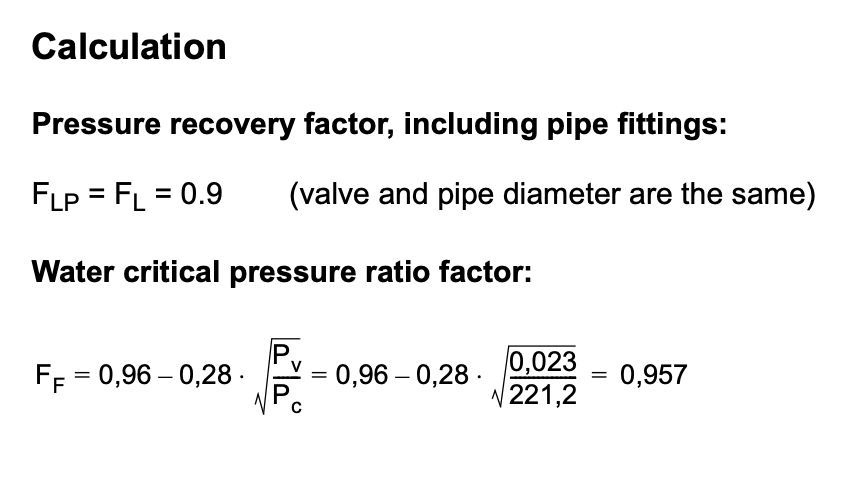

Water flow sizing example

Top entry rotary control valve with Q-Trim is controlling cooling water flow. Valve size is 50 mm. What is required capacity Cv and opening of the valve with given flow data?

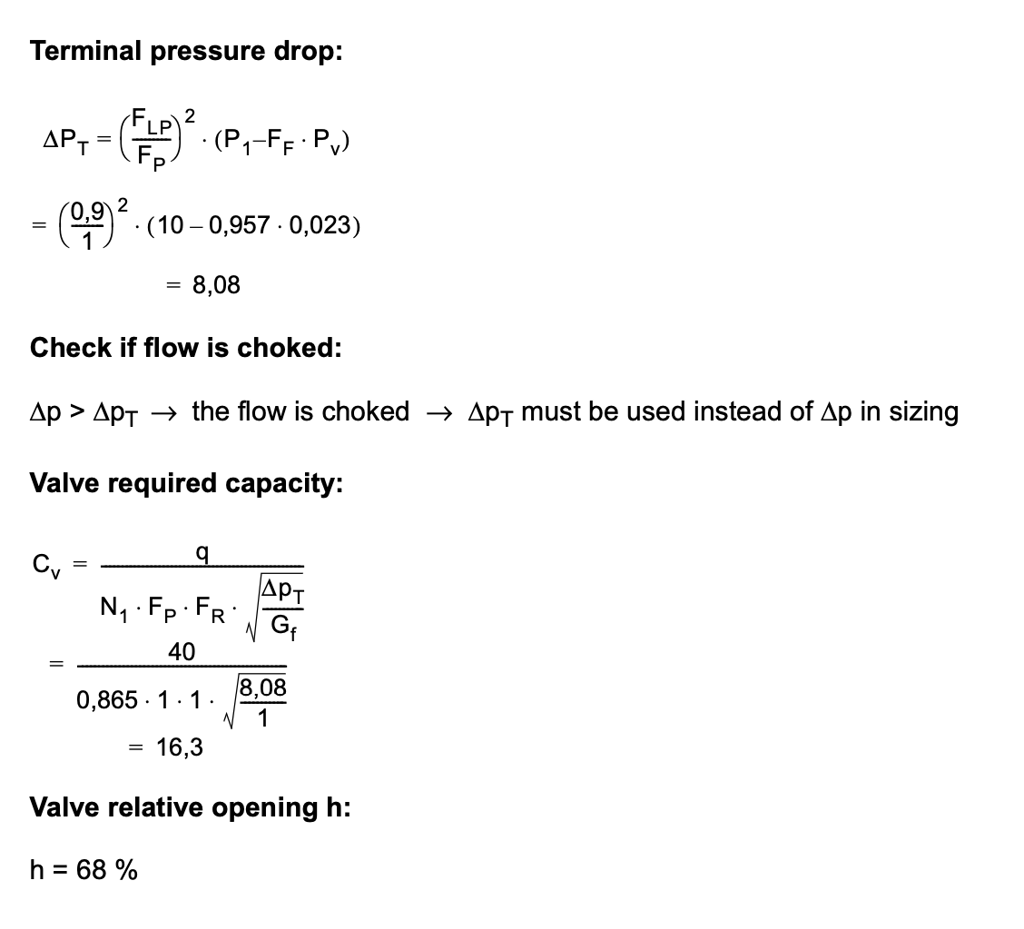

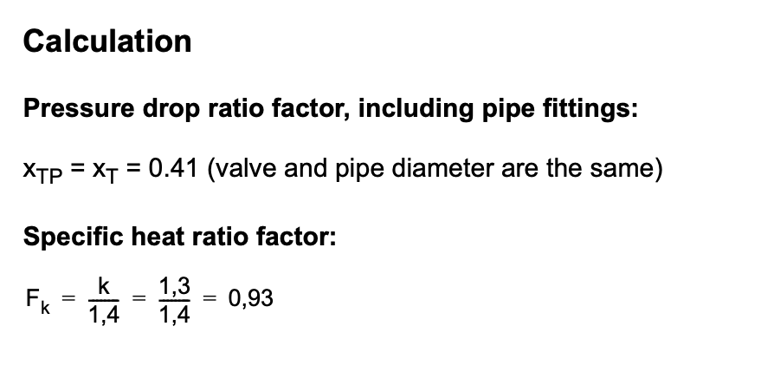

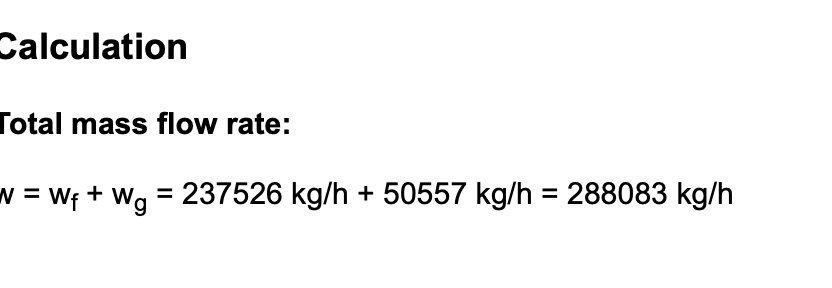

Gas flow sizing example

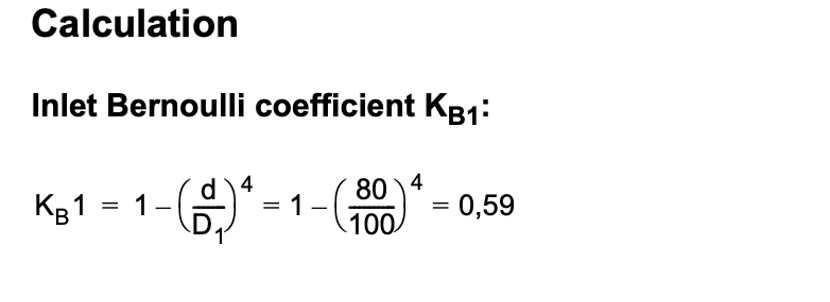

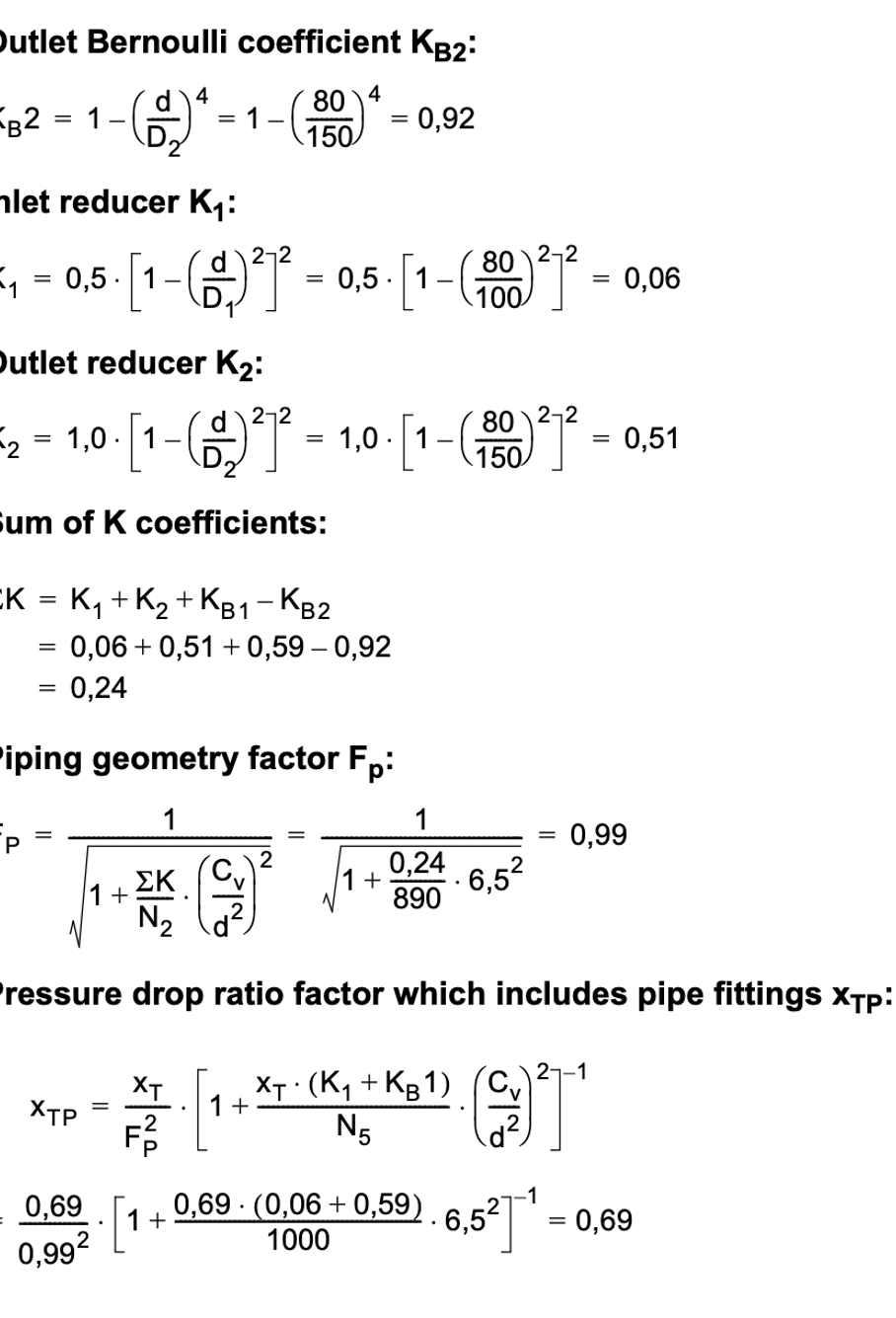

R-series segment valve with Q-Trim is controlling air flow to atmosphere. Valve size is 80 mm. What is required capacity Cv and opening of the valve with given flow data?

Steam flow sizing example

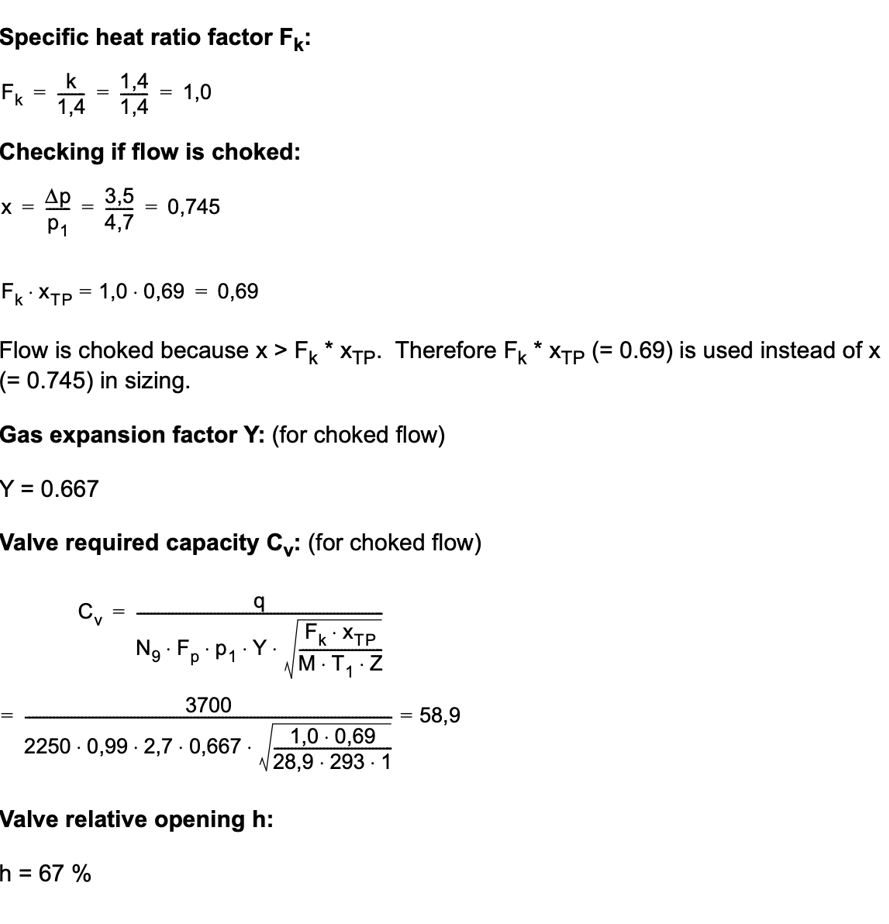

L-series butterfly valve is controlling saturated steam flow. Valve size is 100 mm. What is required capacity Cv and opening of the valve with given flow data?

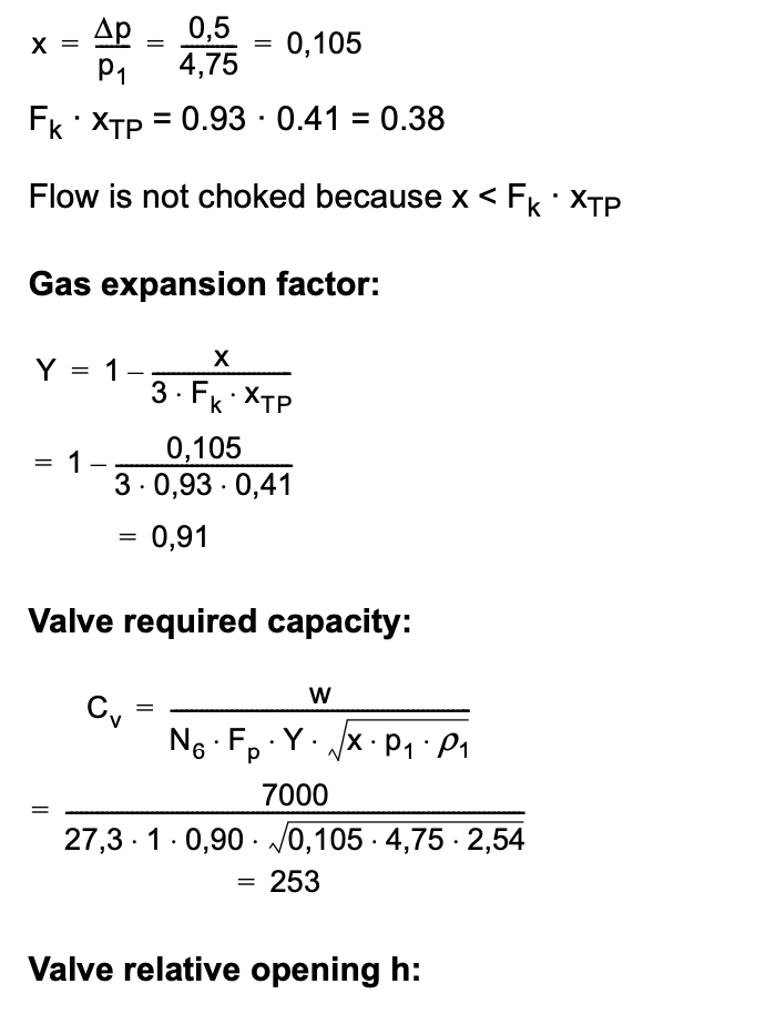

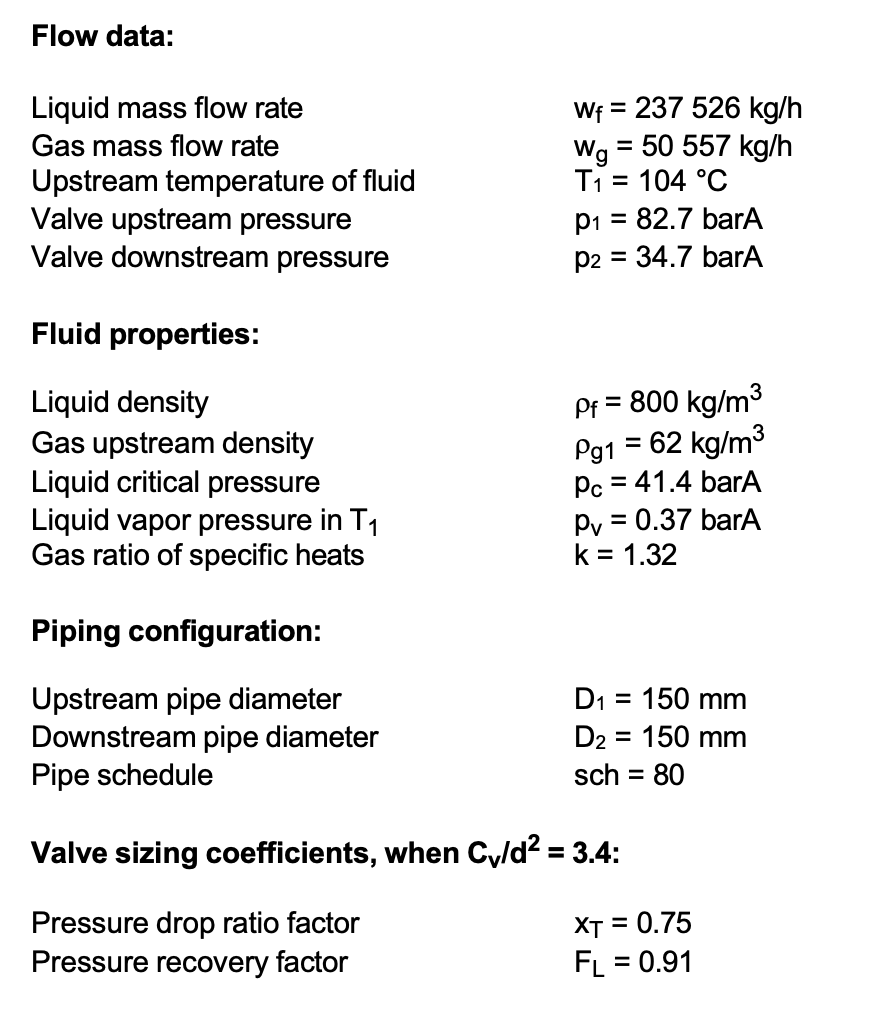

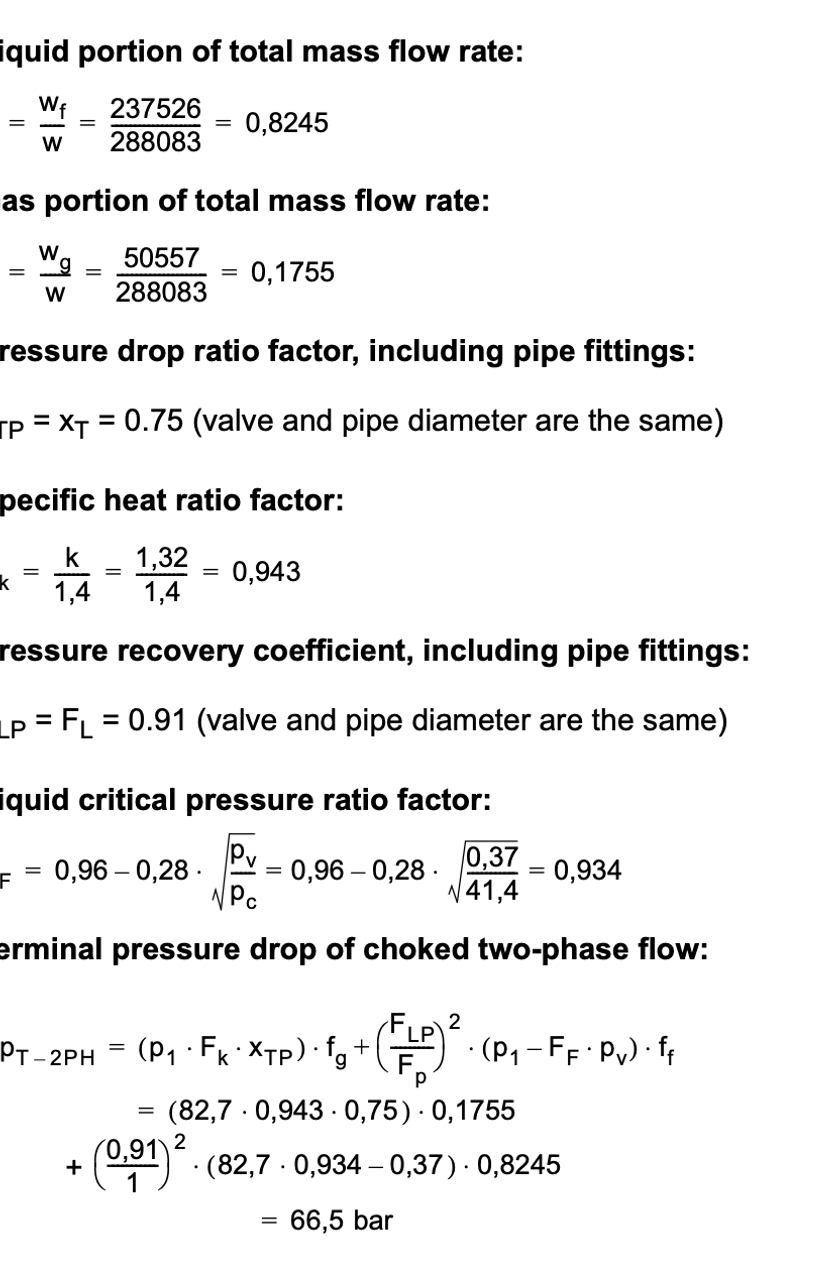

Two phase flow of liquid and gas sizing example

Top entry rotary control valve with Q-Trim is controlling mixture of crude oil and natural gas. Valve size is 150 mm. What is required capacity Cv and opening of the valve with given flow data?

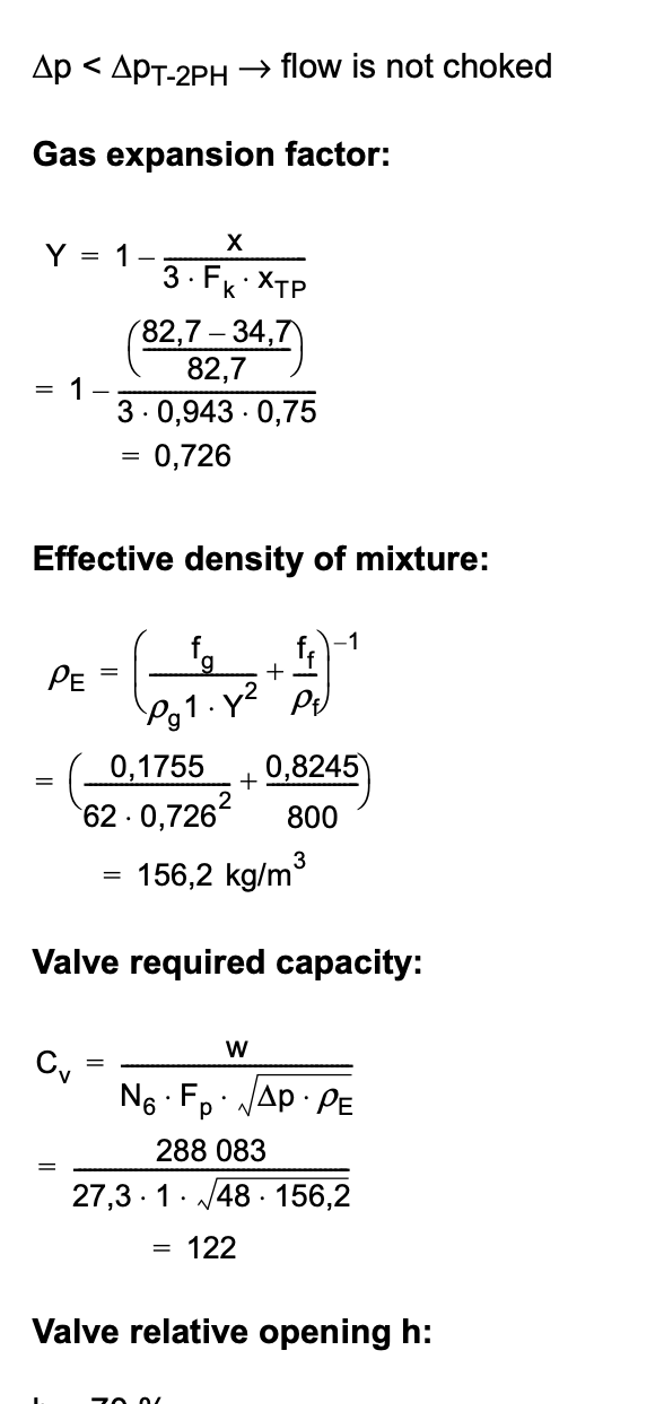

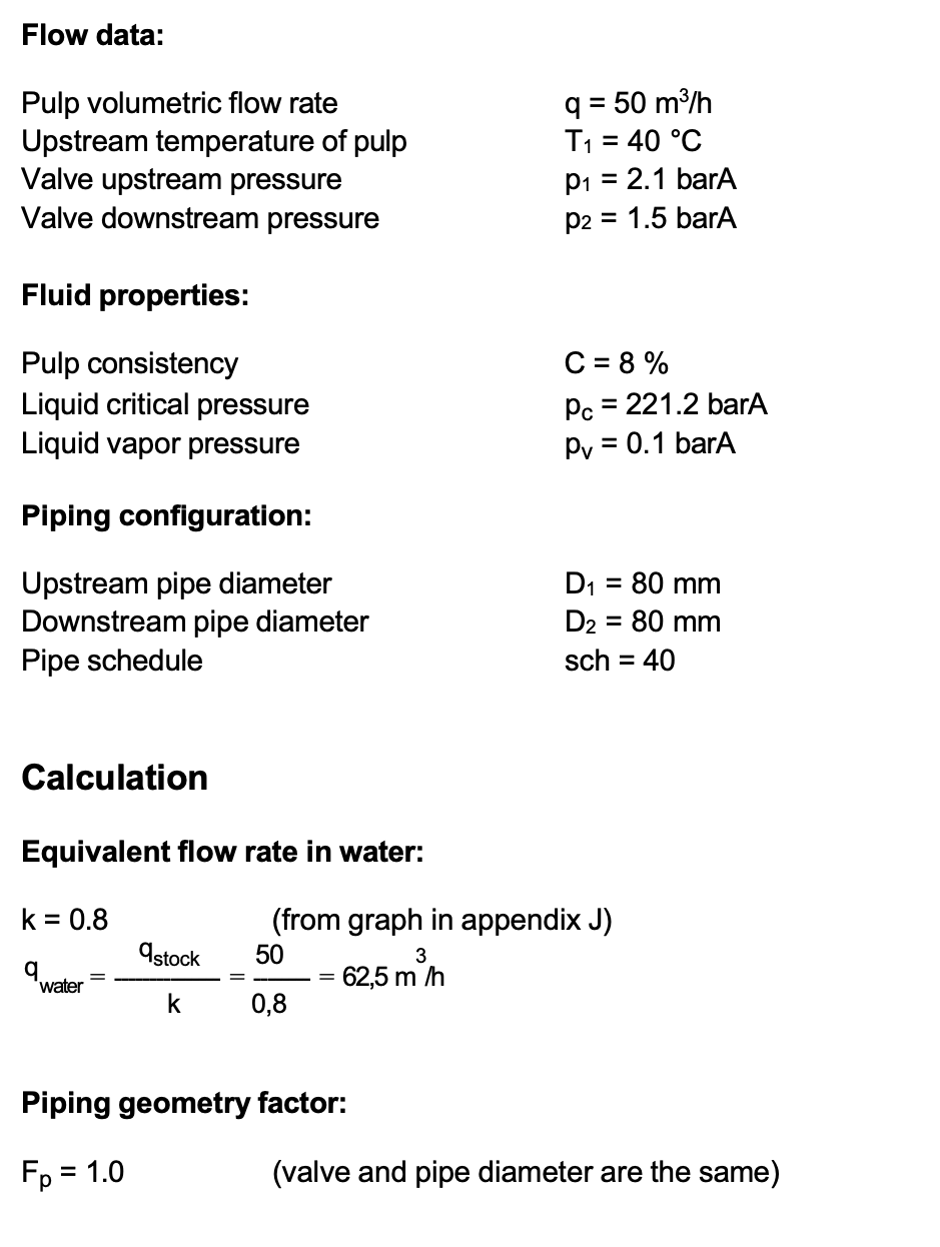

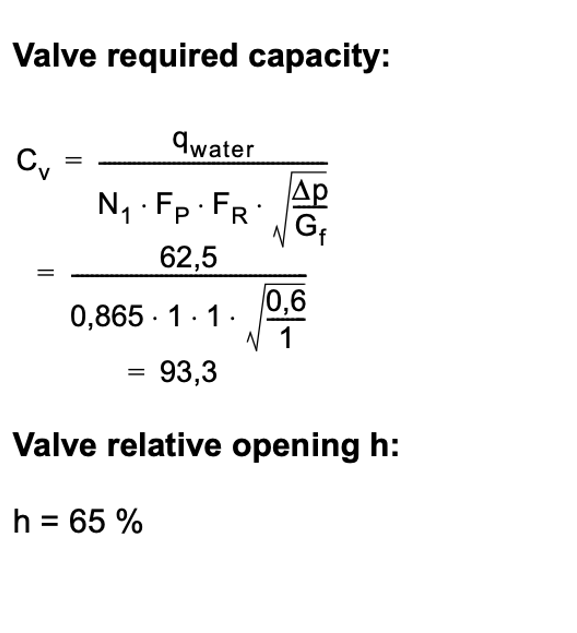

Pulp flow sizing example

R-series segment valve is controlling flow of mechanical stock. Valve size is 80 mm. What is required capacity Cv and opening of the valve with given flow data?

B Conversion tables

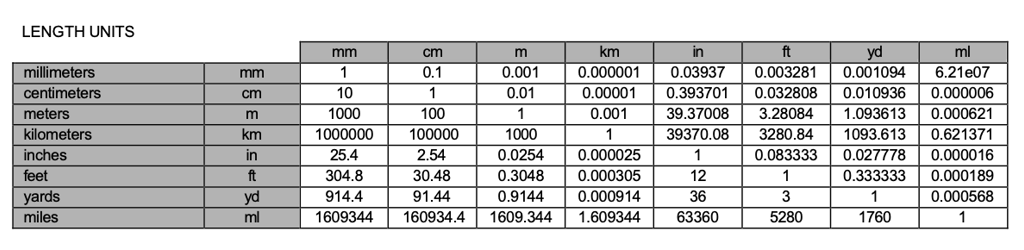

Length units

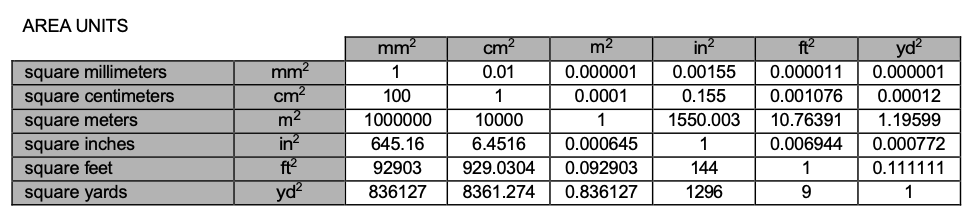

Area units

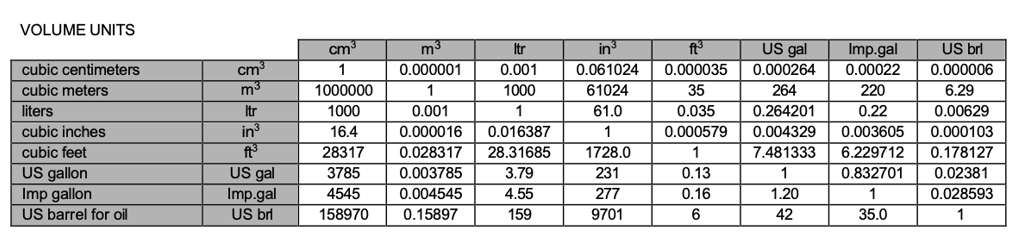

Volume units

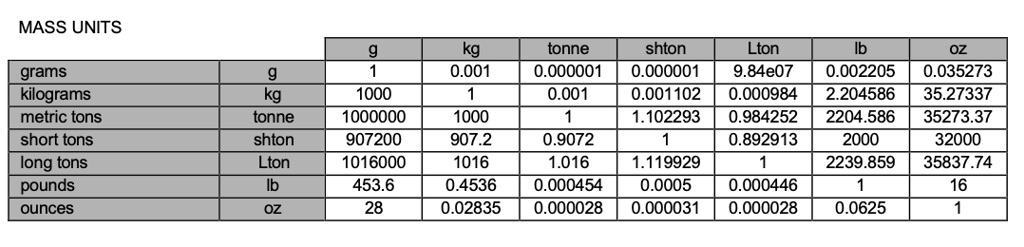

Mass units

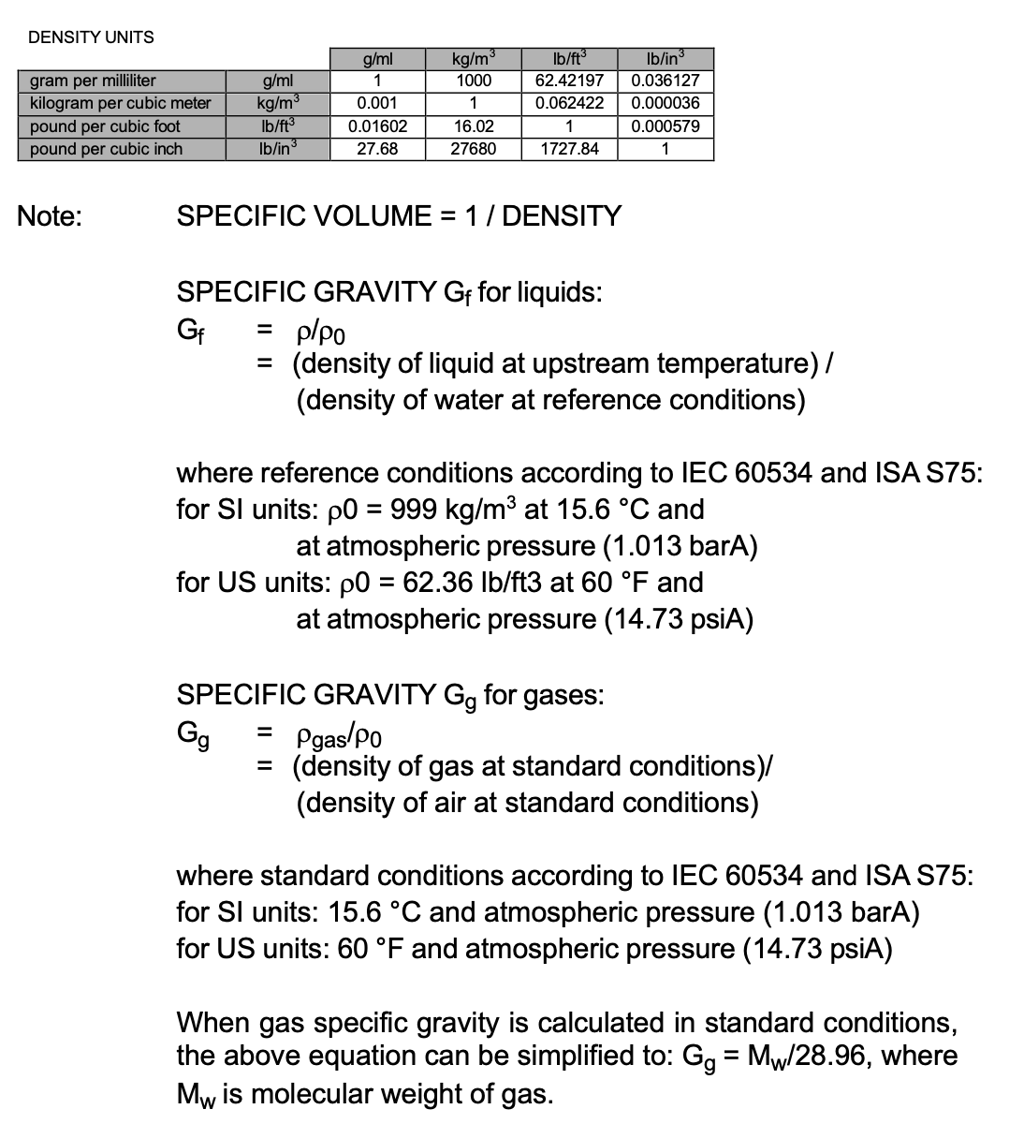

Density units

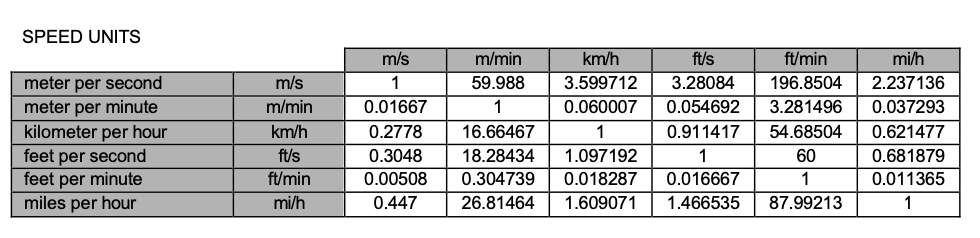

Speed units

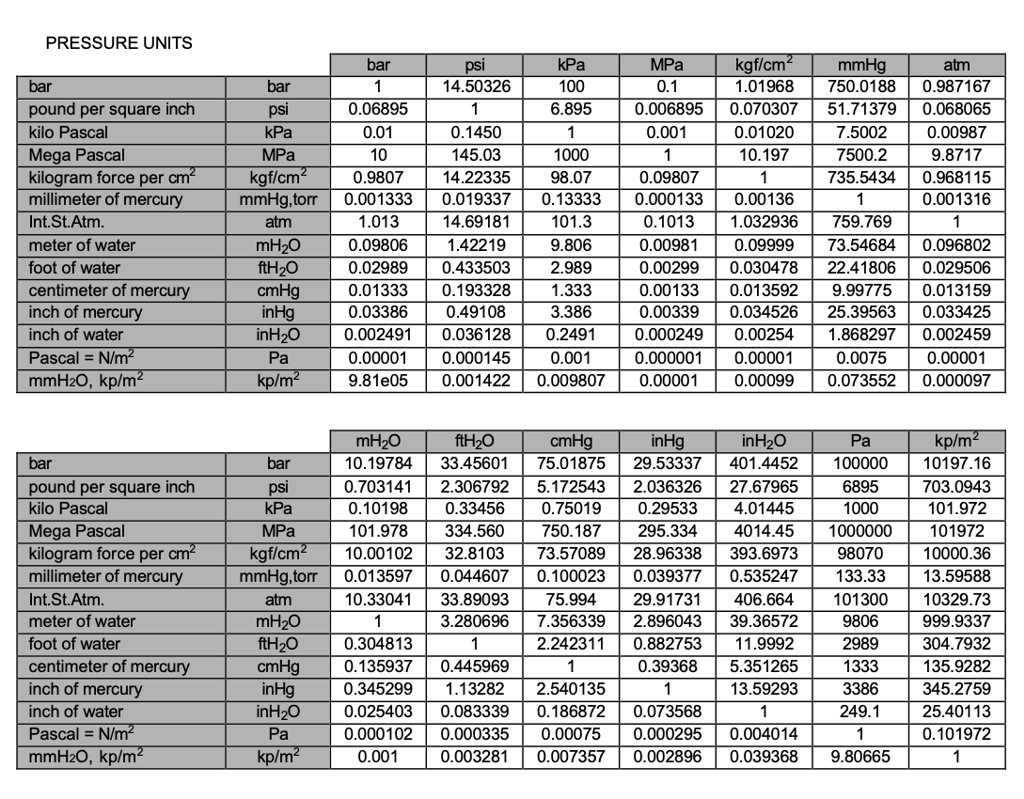

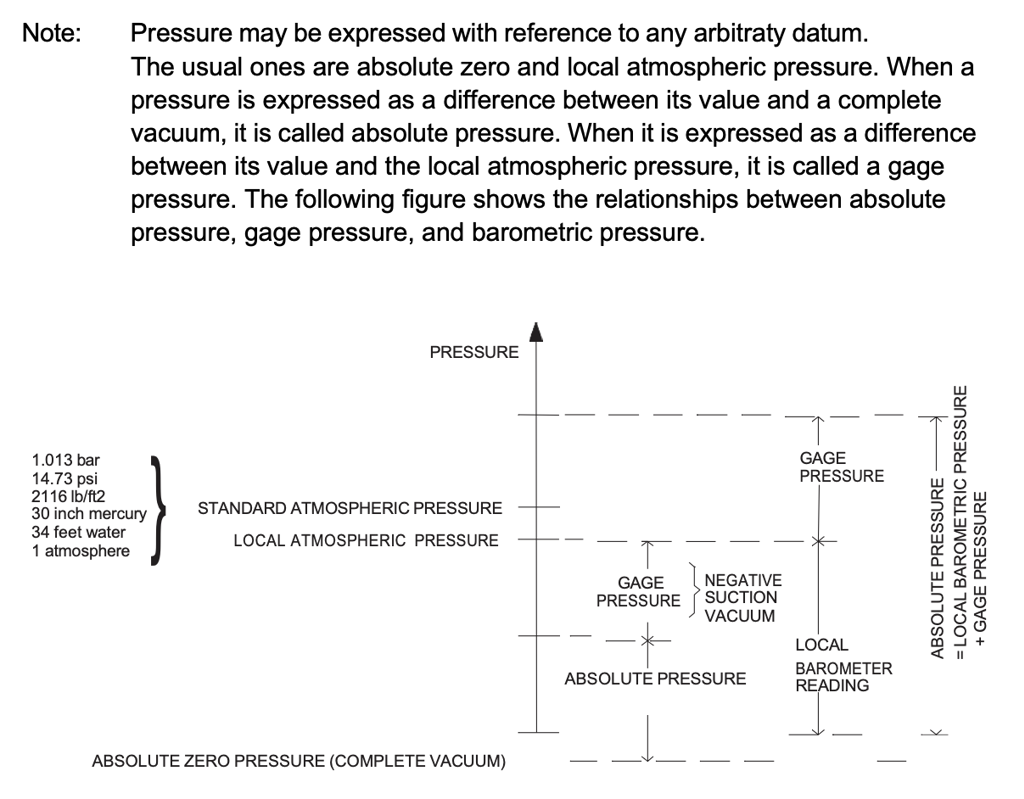

Pressure units

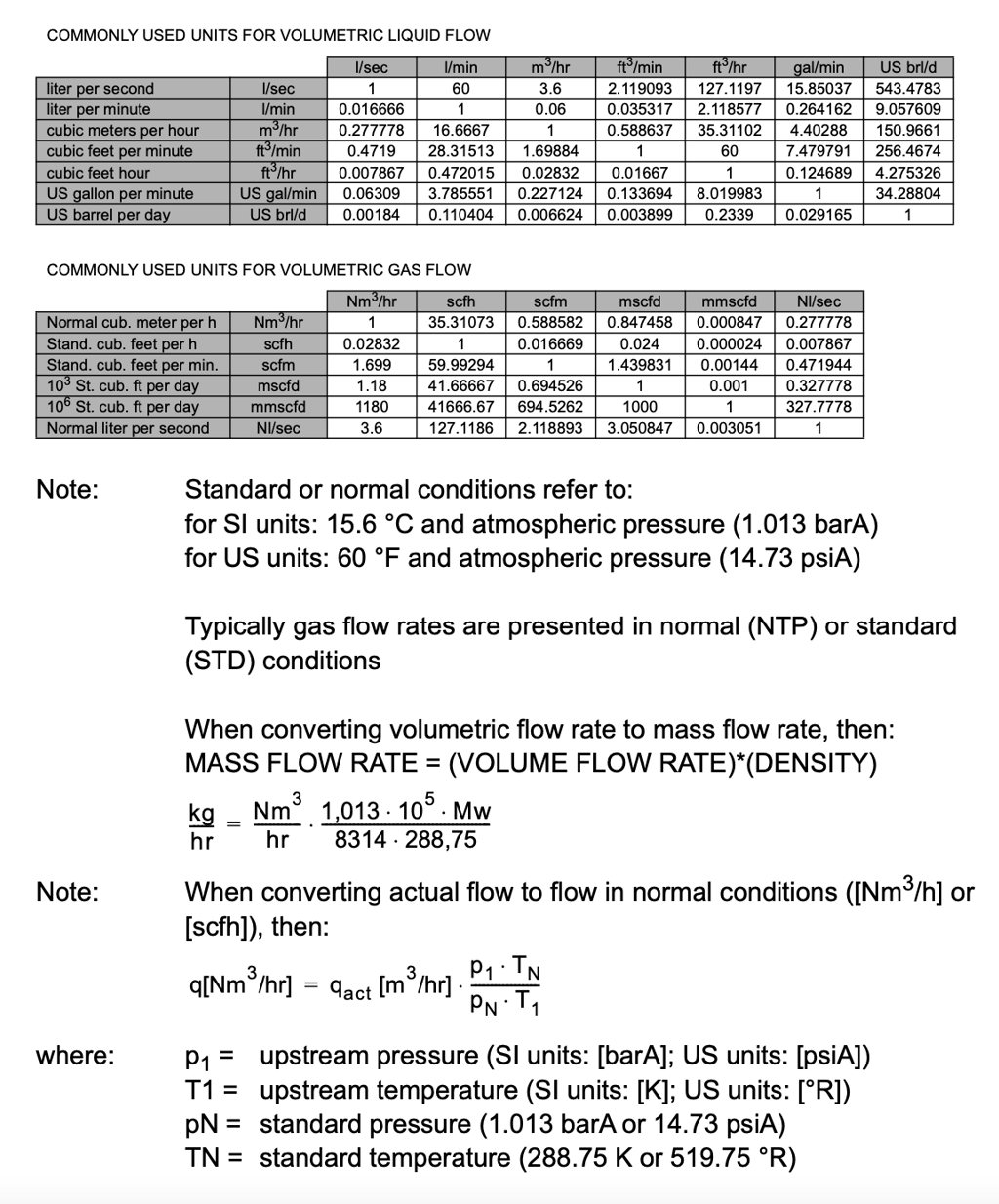

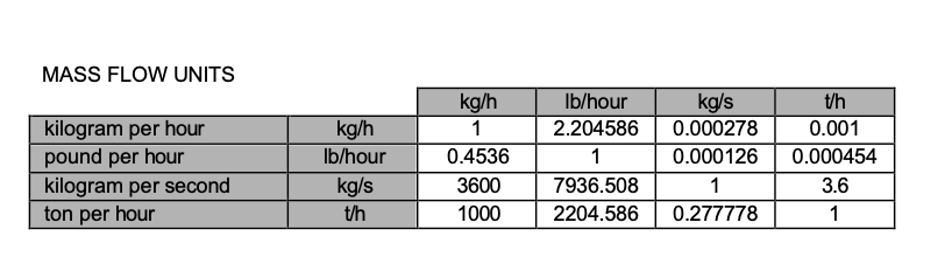

Flow units

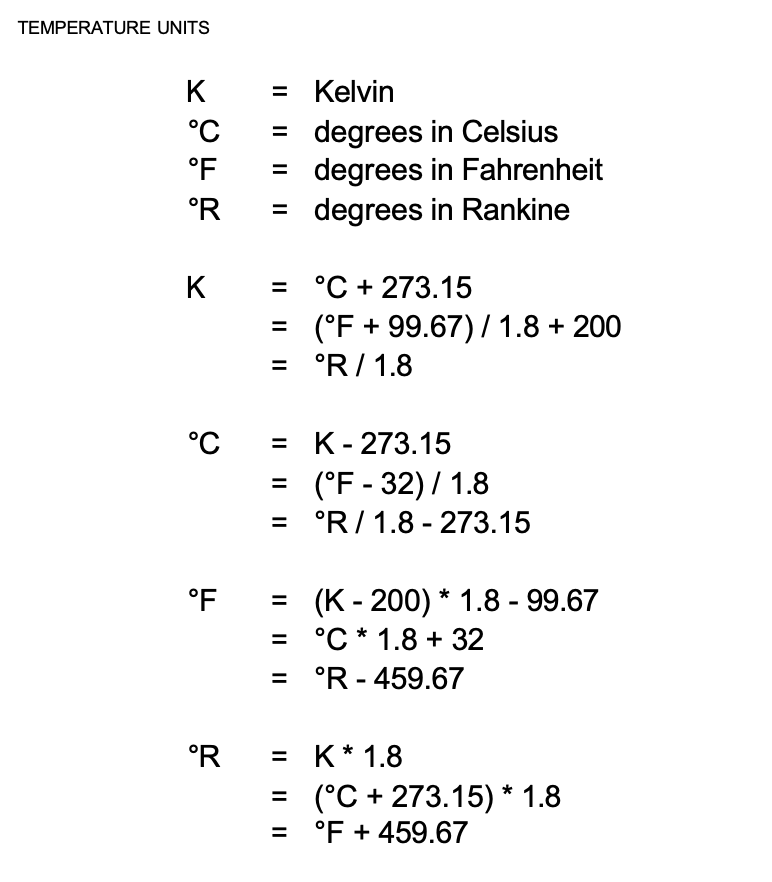

Temperature units

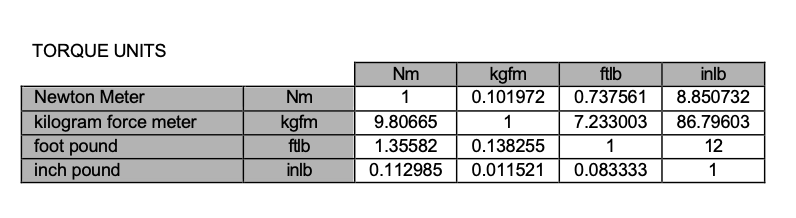

Torque units

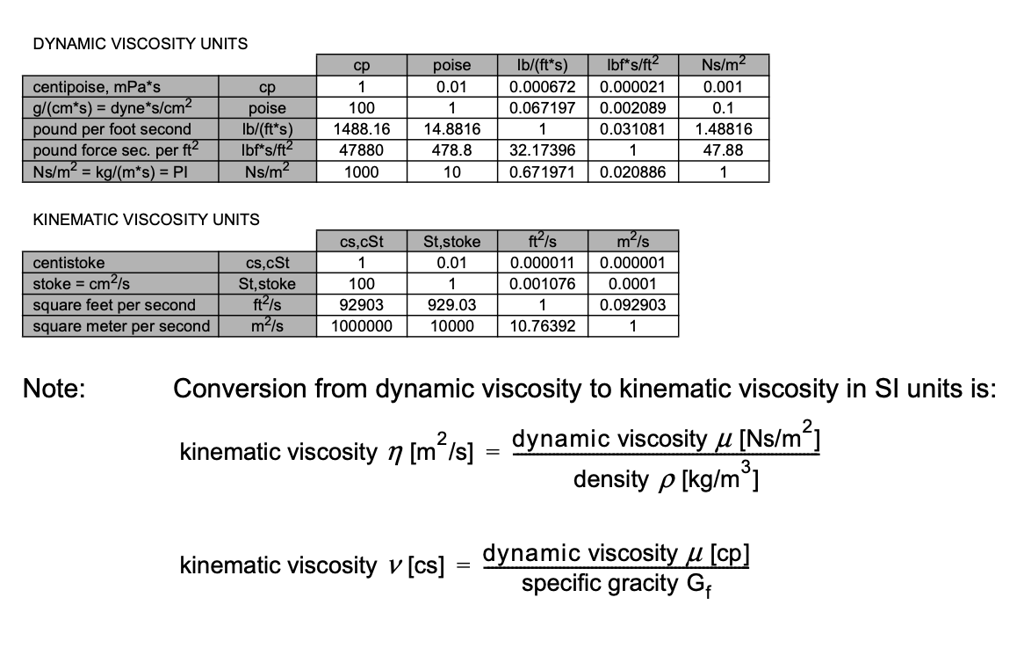

Viscosity units

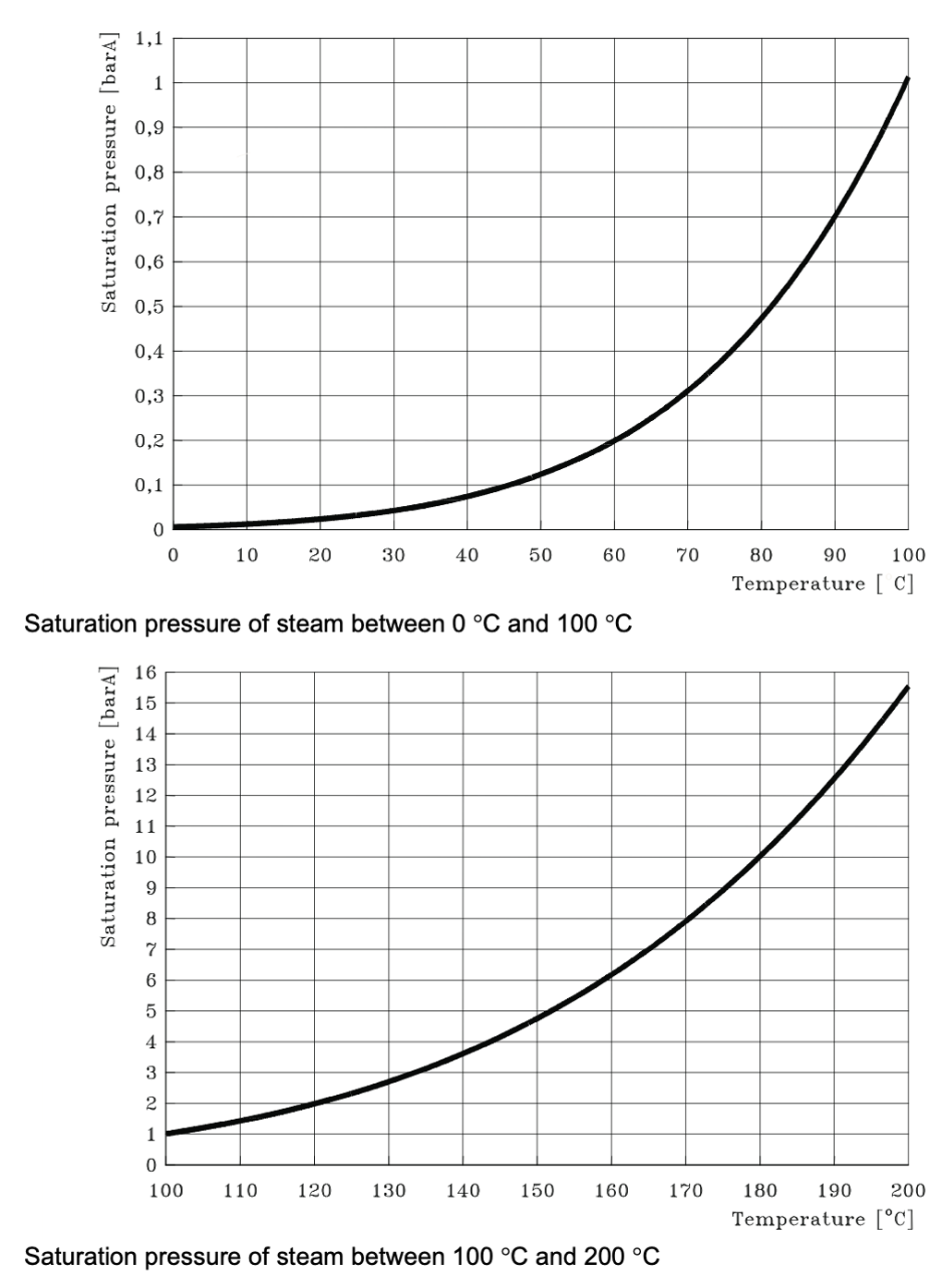

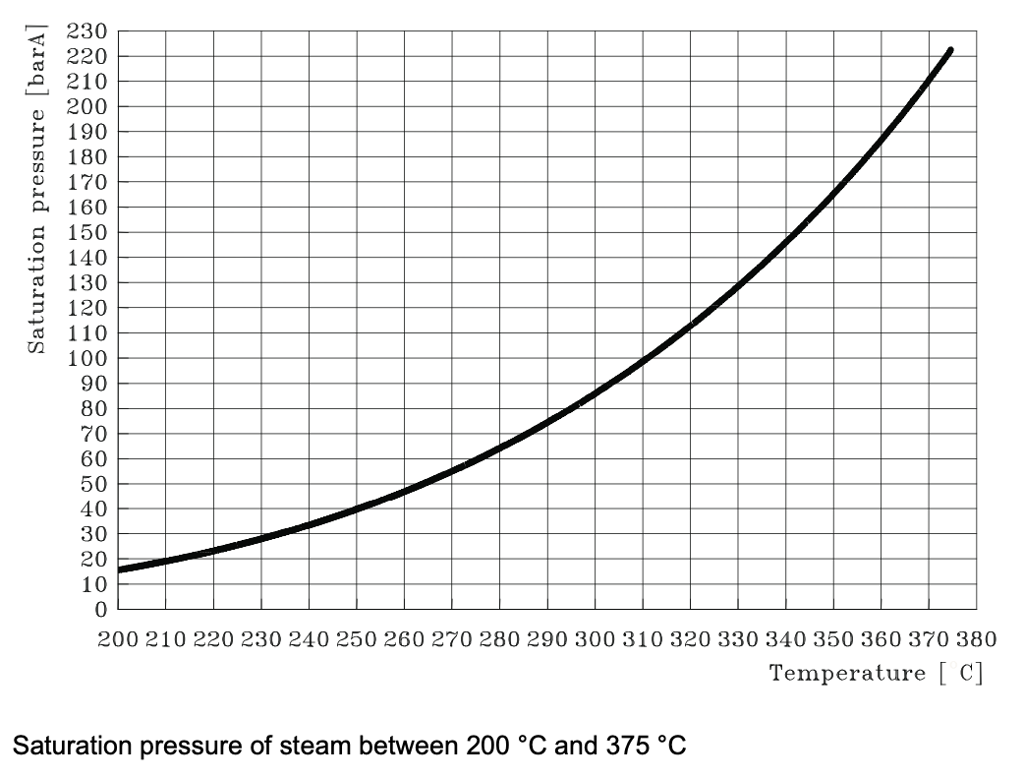

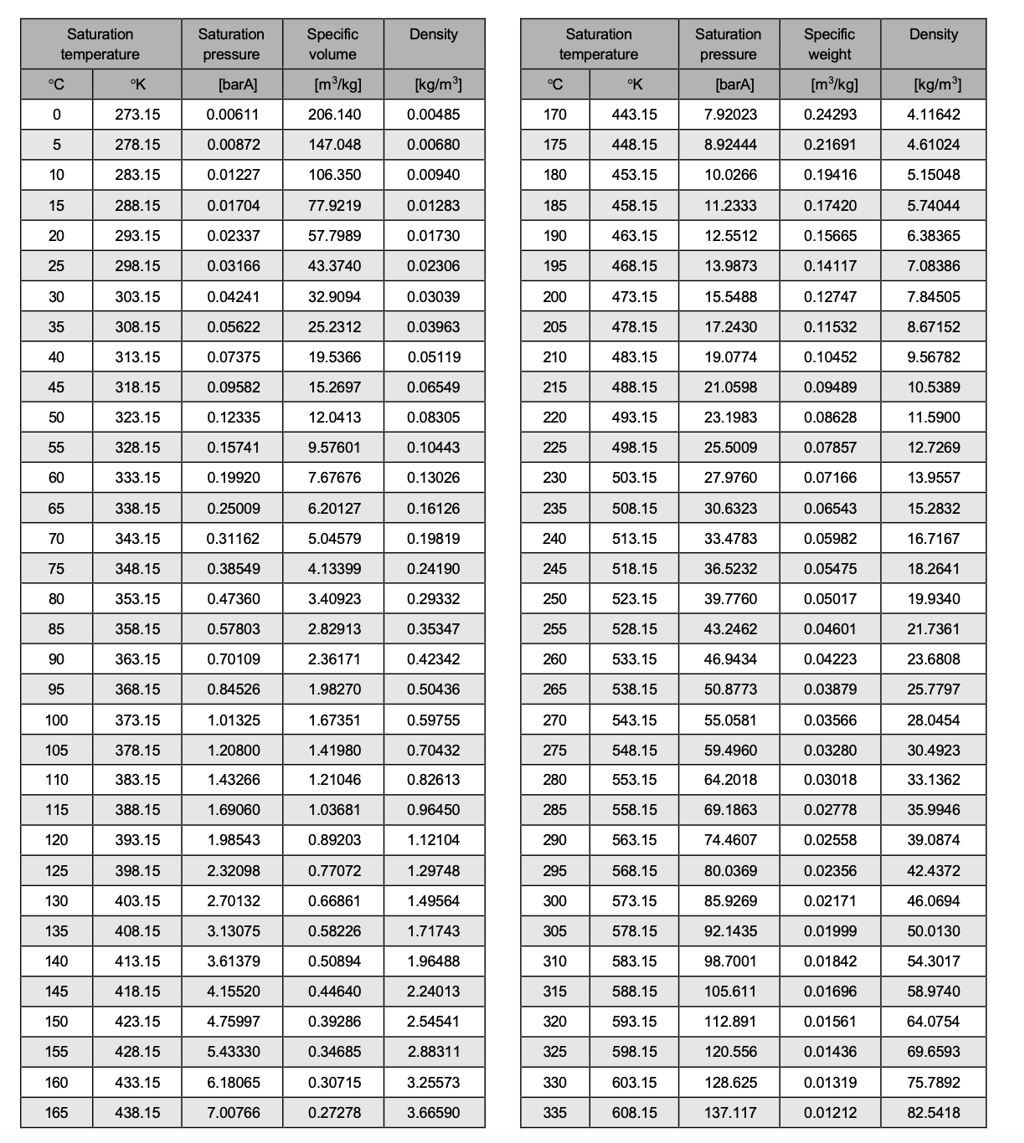

C Steam

Saturated pressure of steam

Density of saturated steam

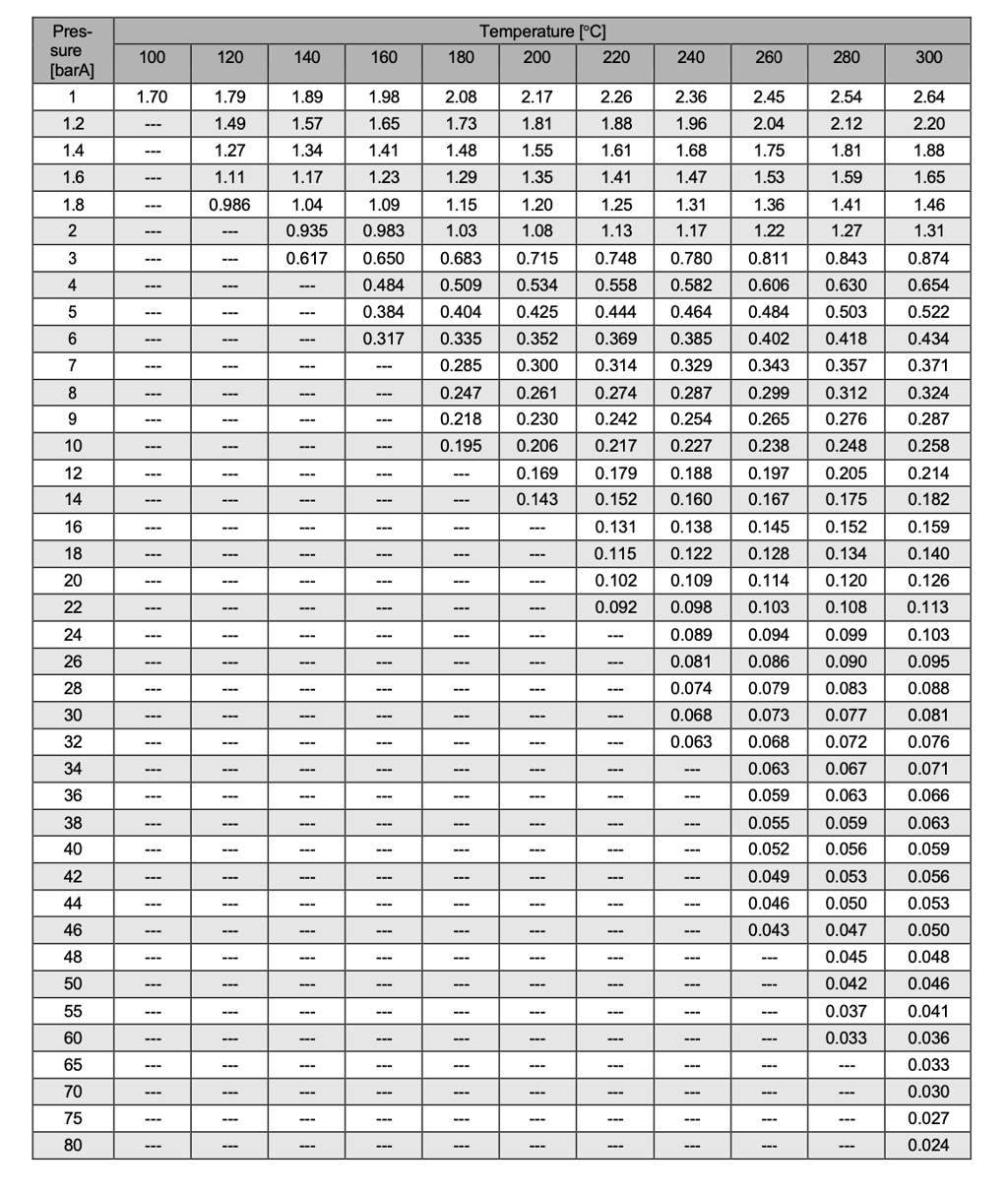

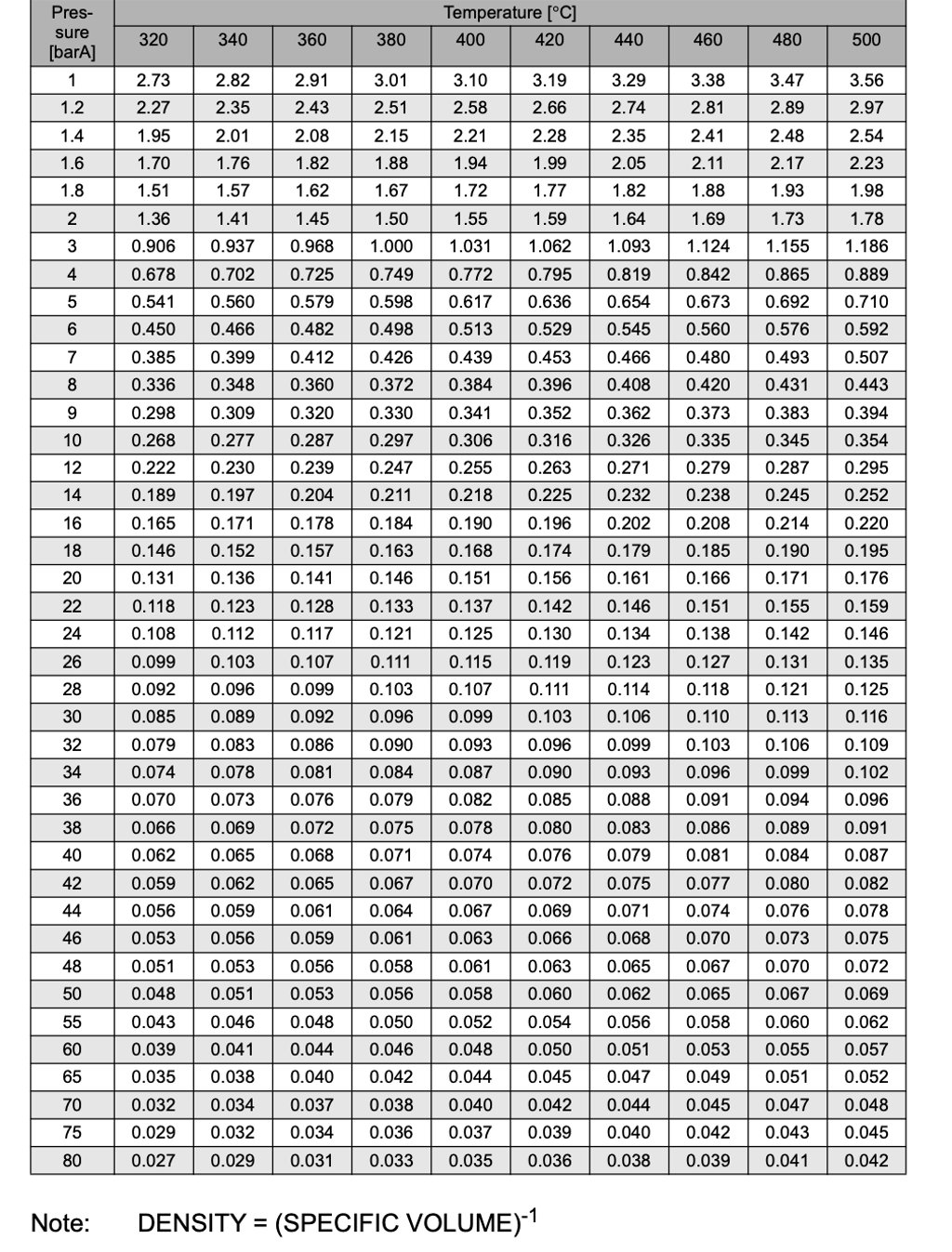

D Superheated steam

Specific volume (V) (unit: [m3/kg]) as a function of temperature (unit: [°C]) and pressure (unit: [barA]).

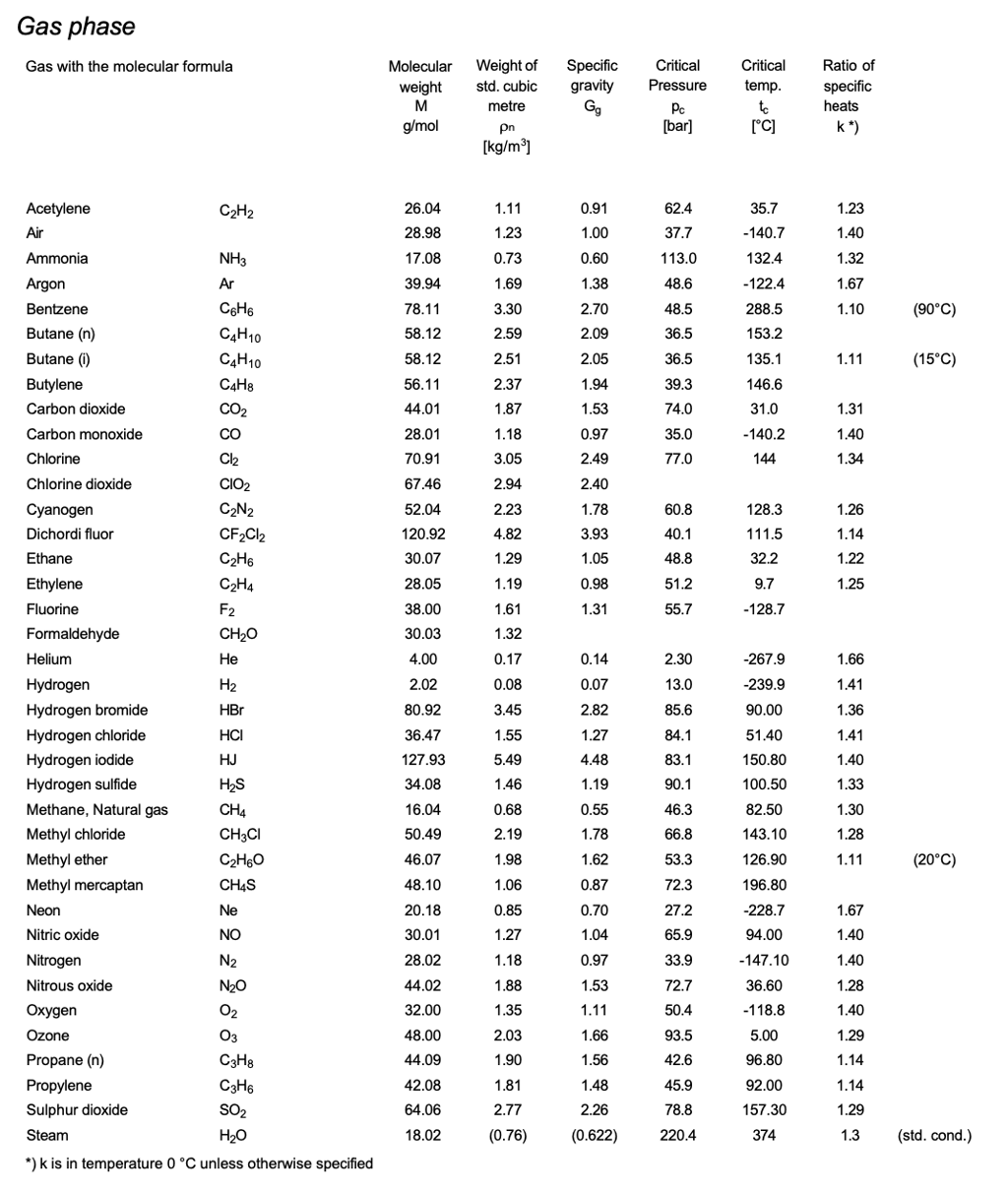

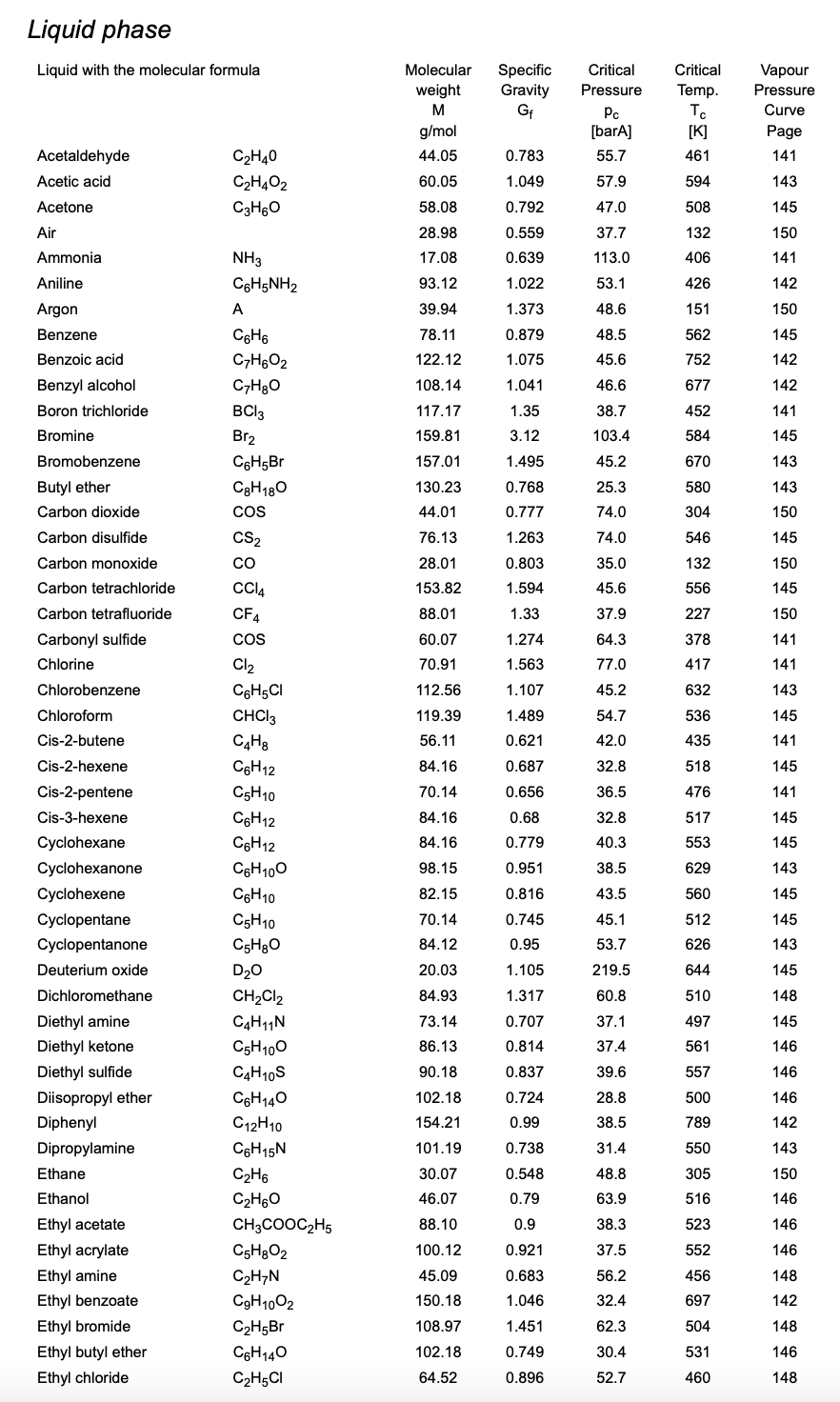

E Physical constants

Gases

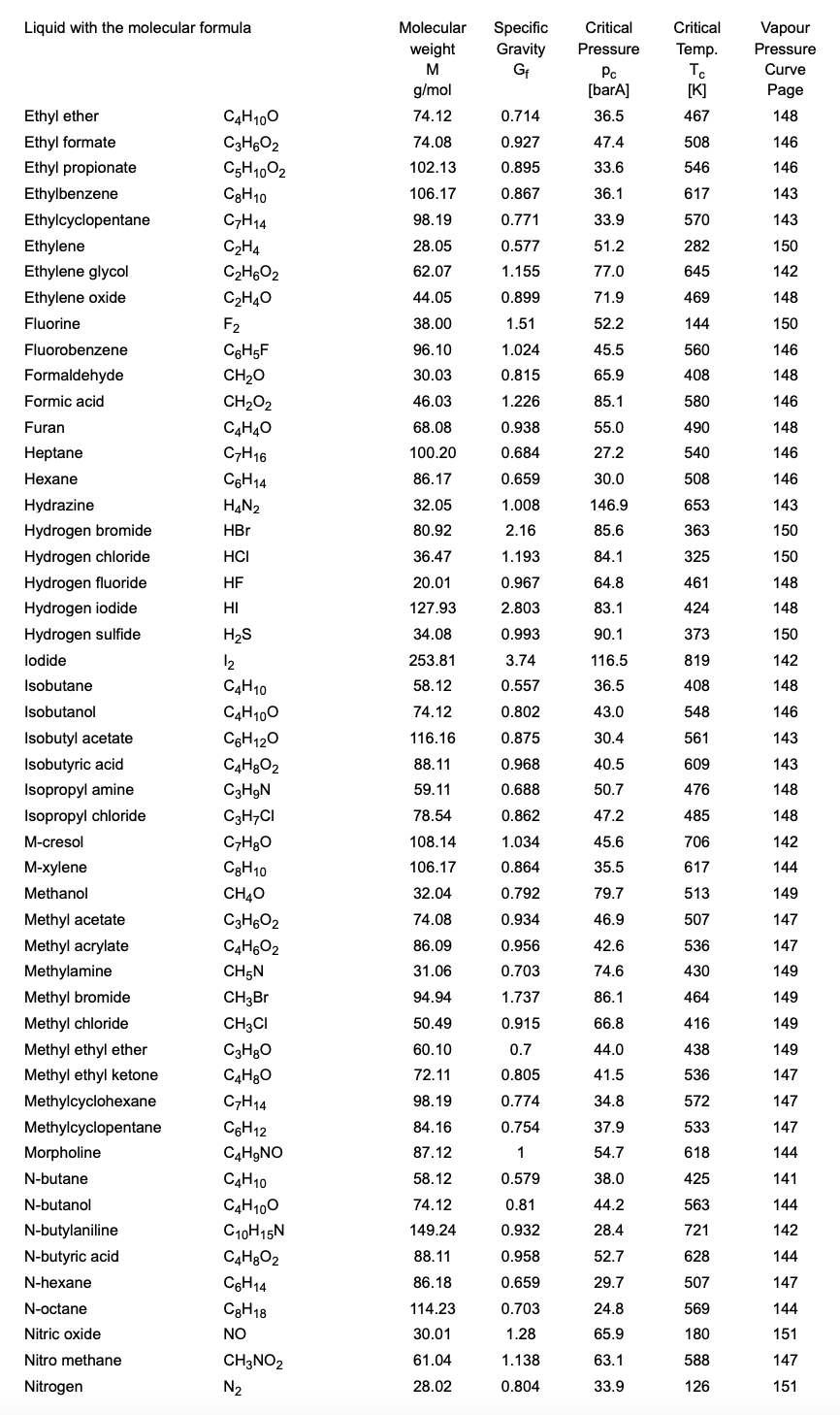

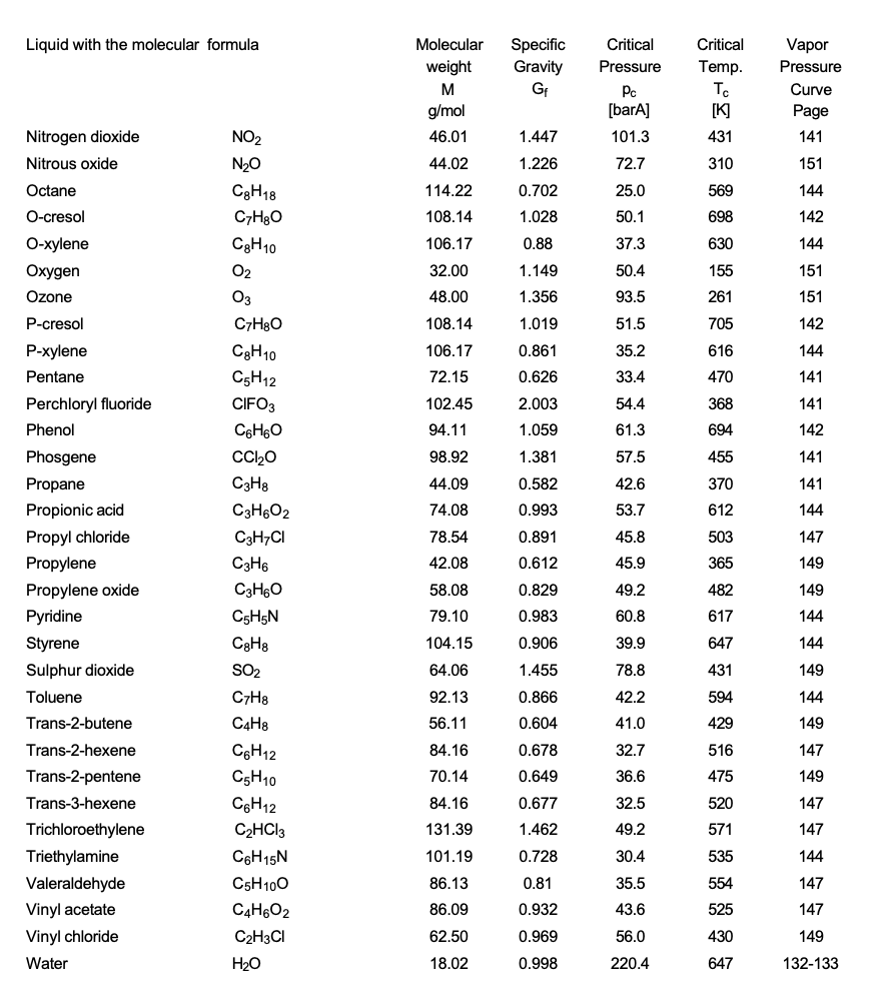

Liquids

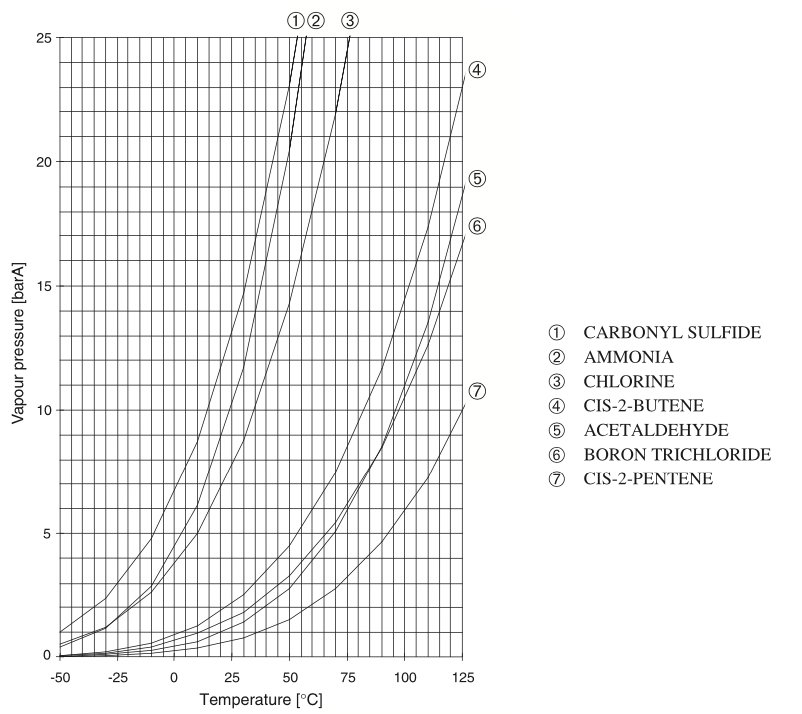

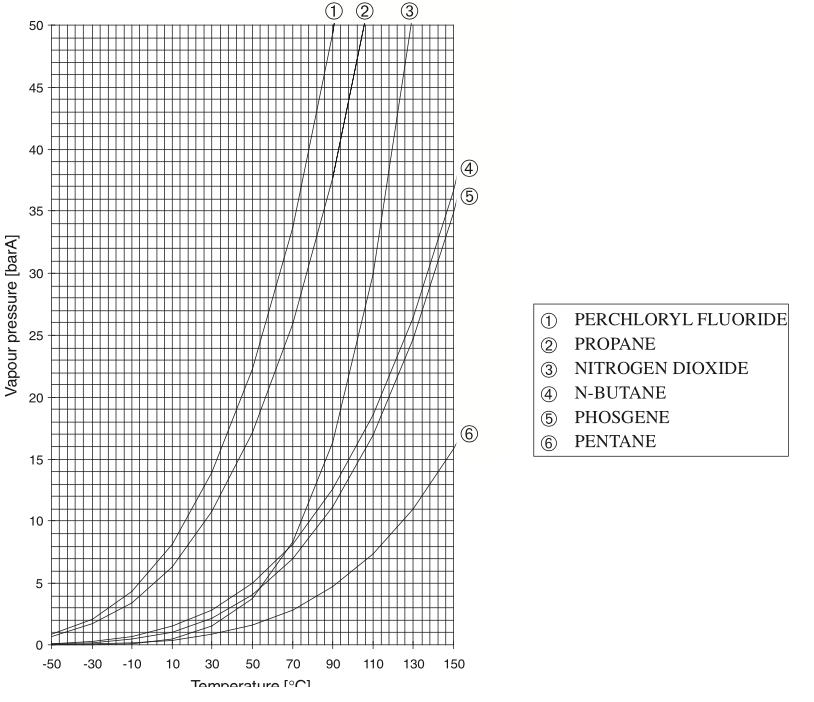

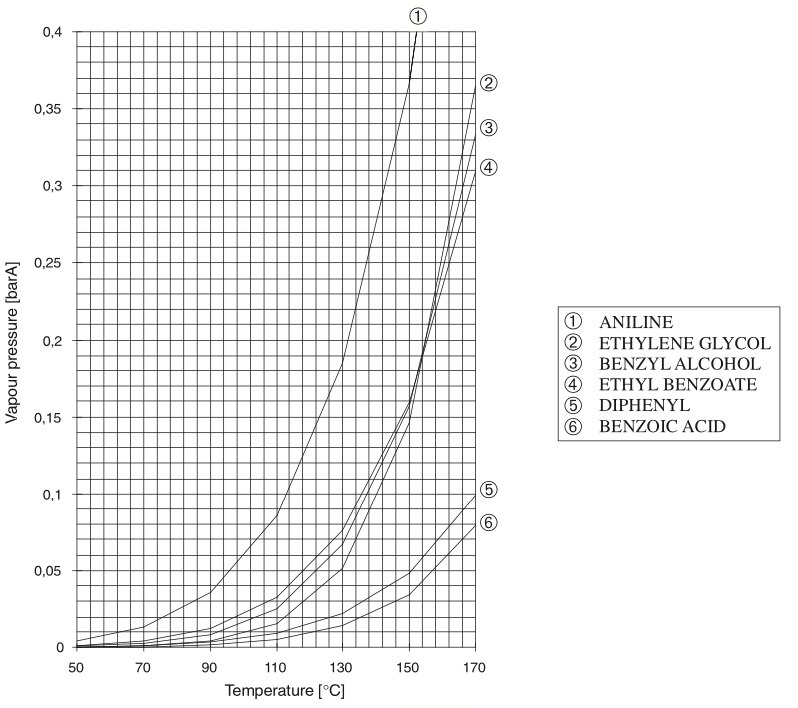

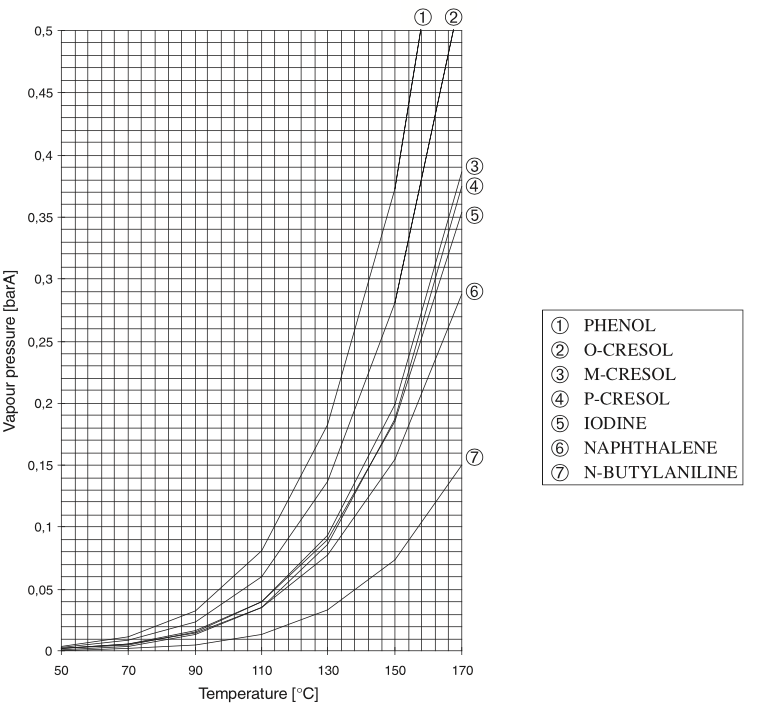

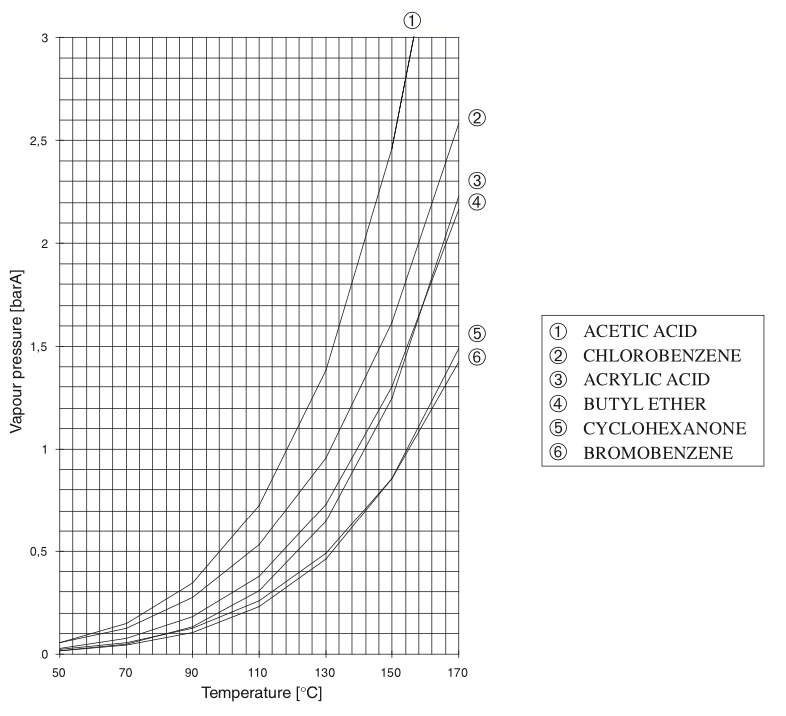

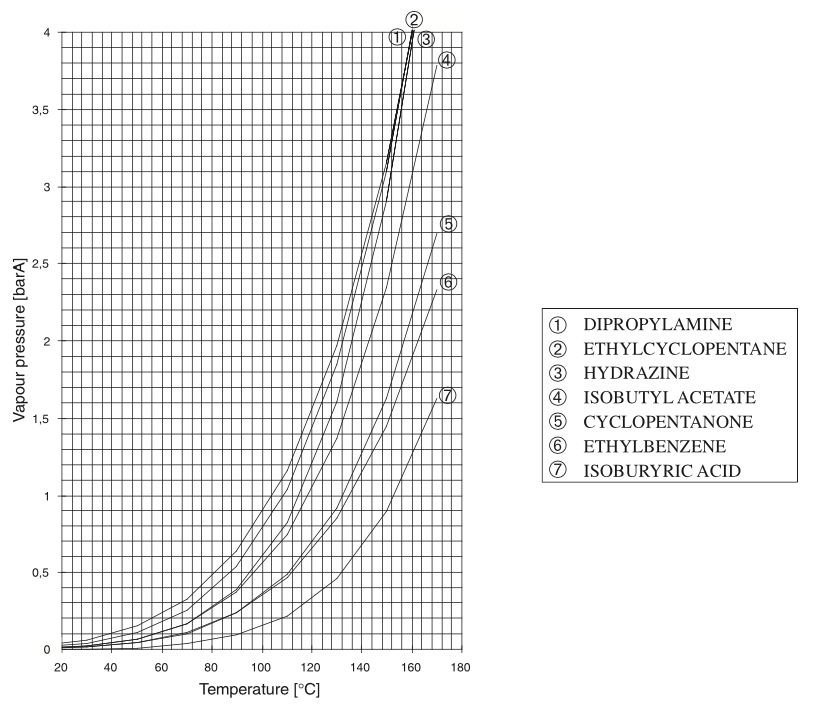

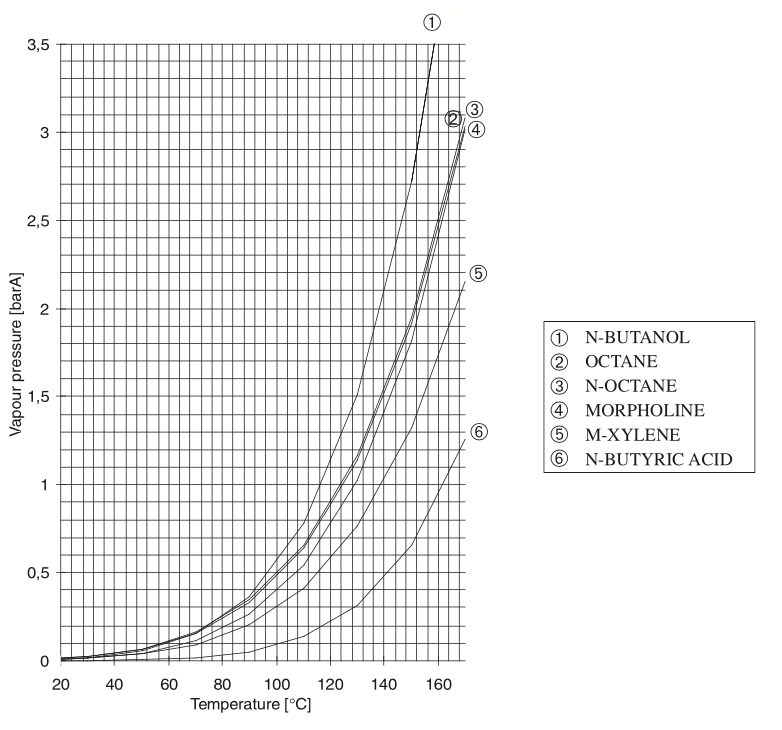

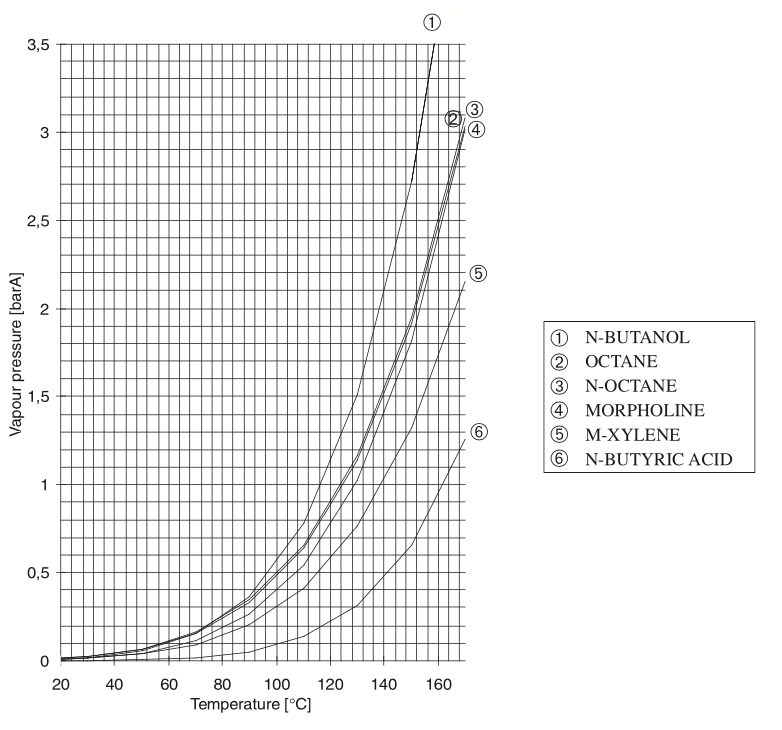

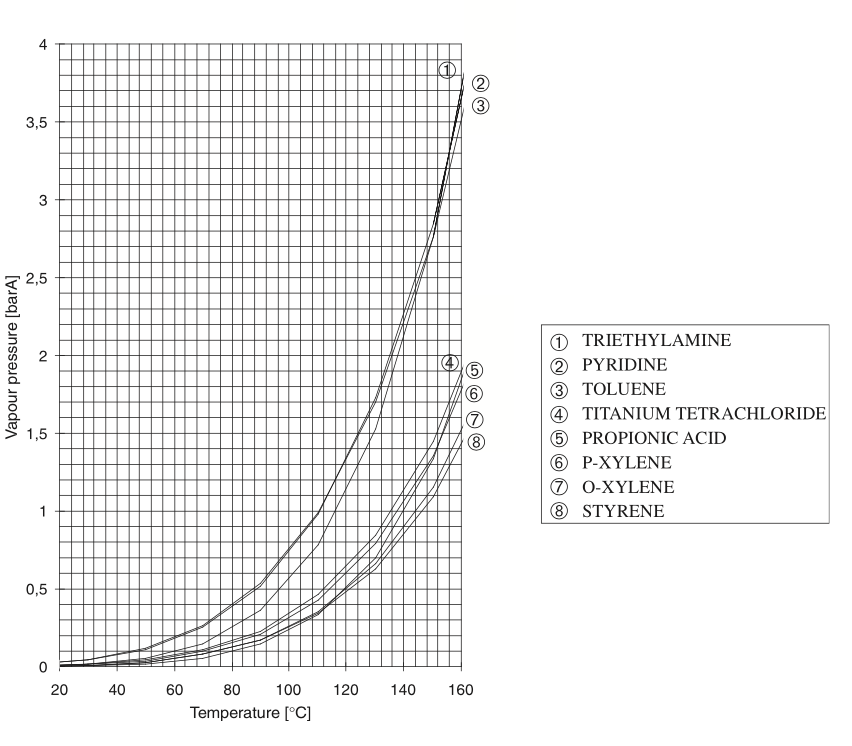

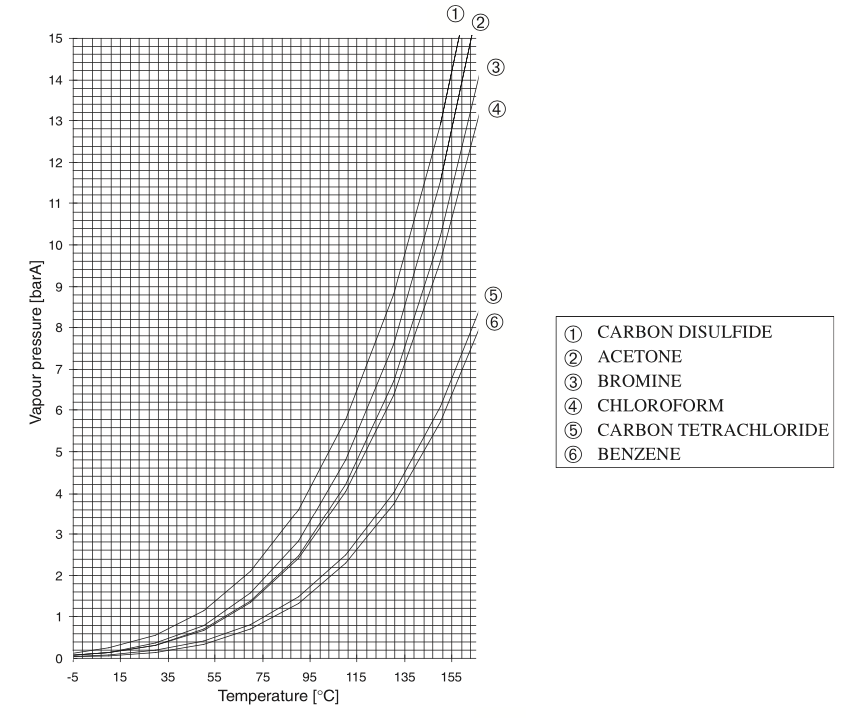

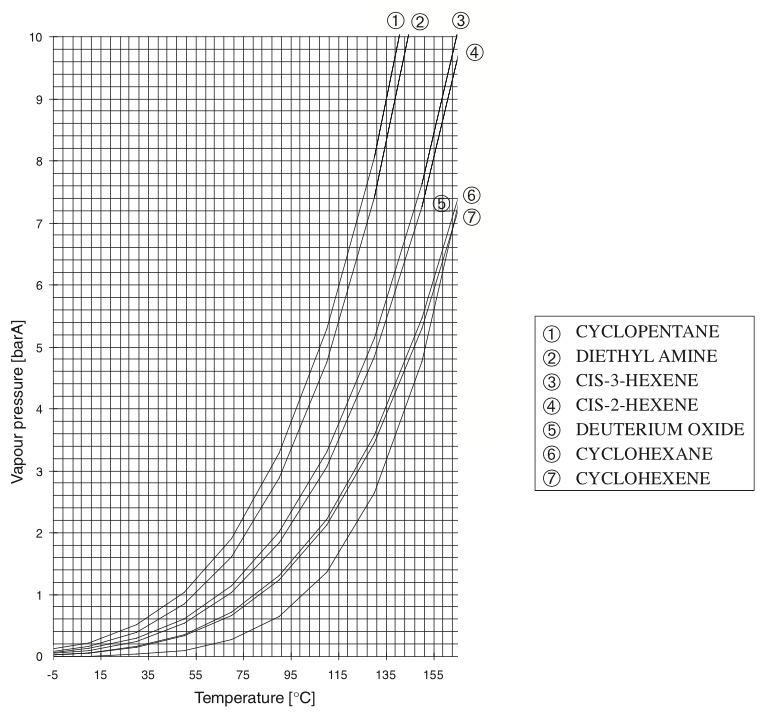

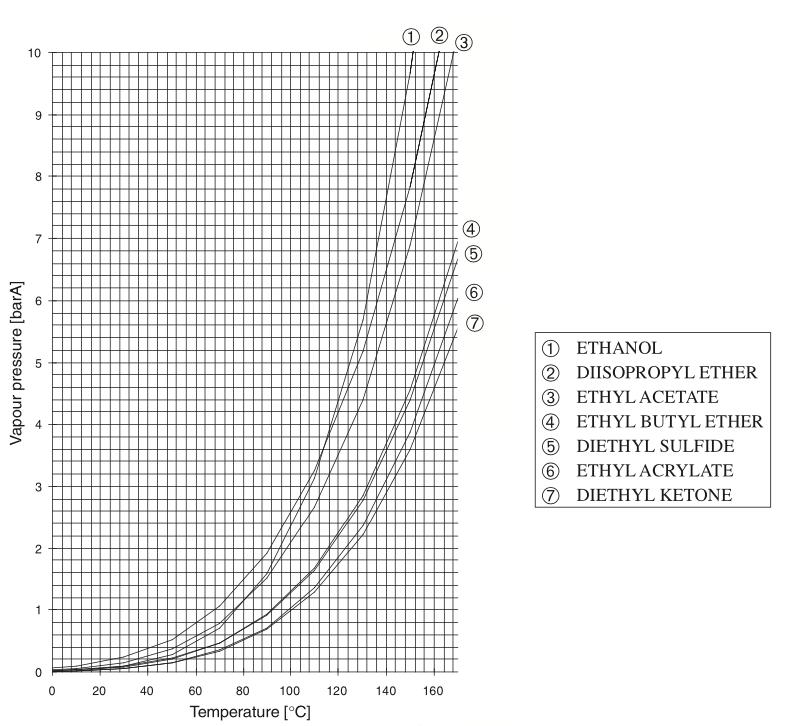

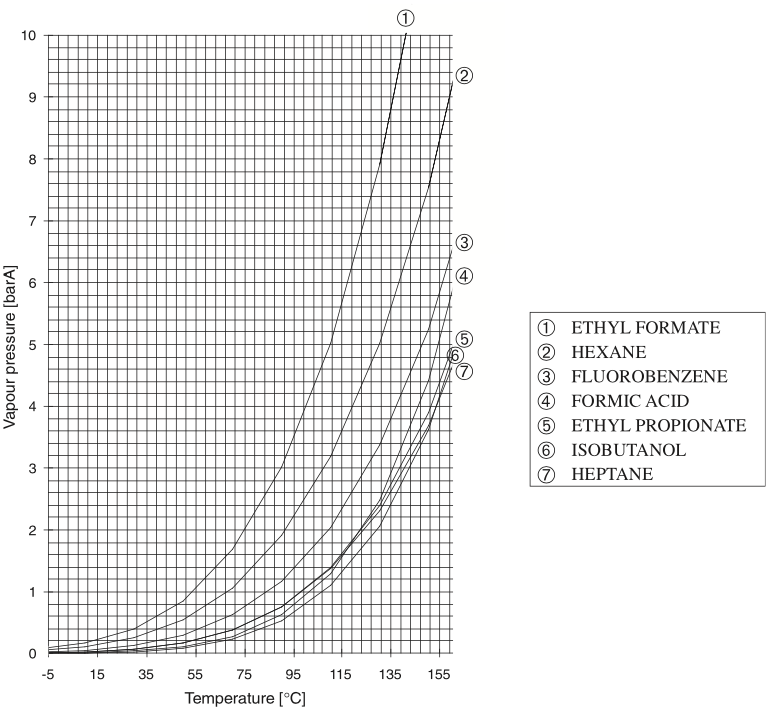

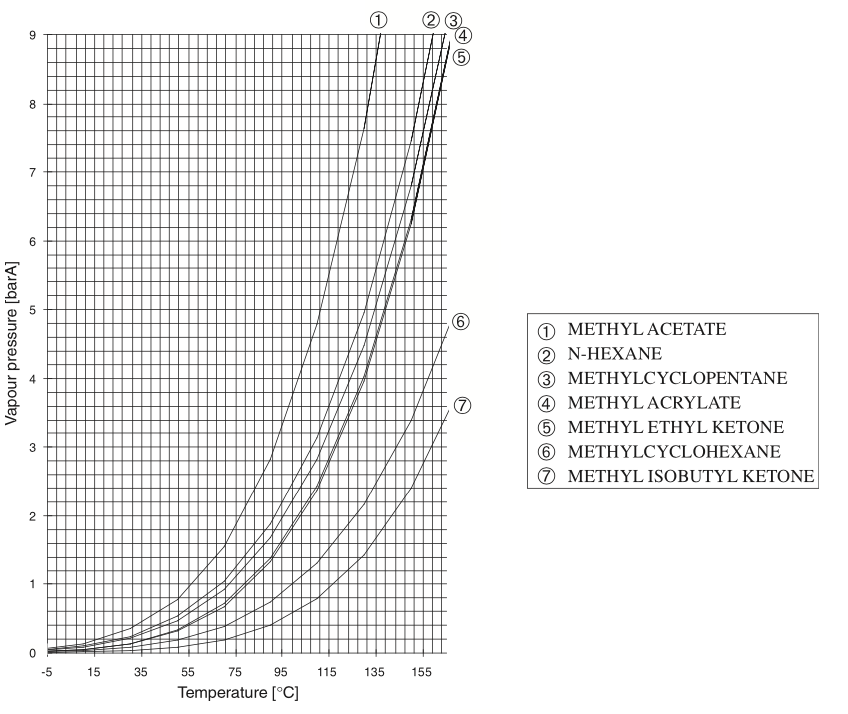

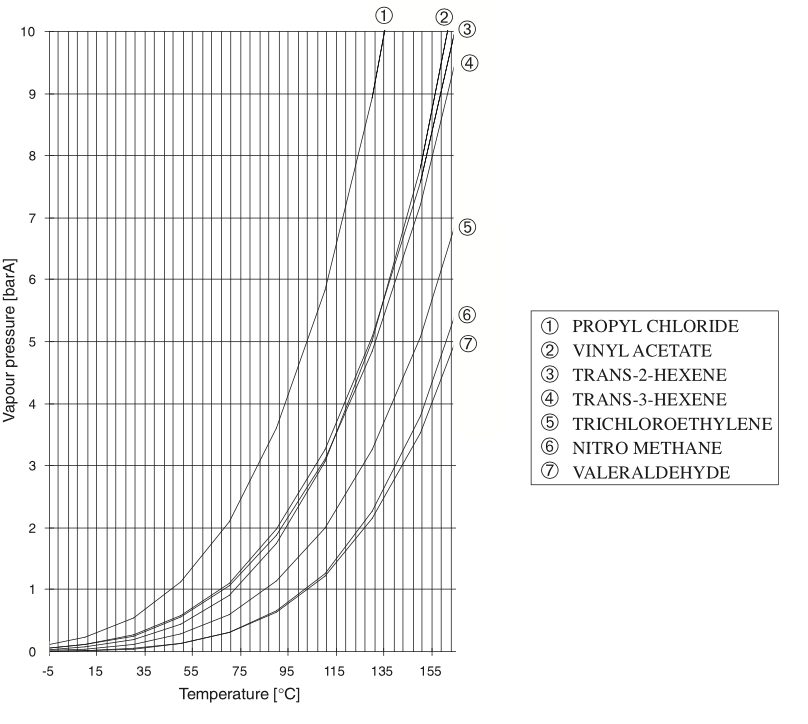

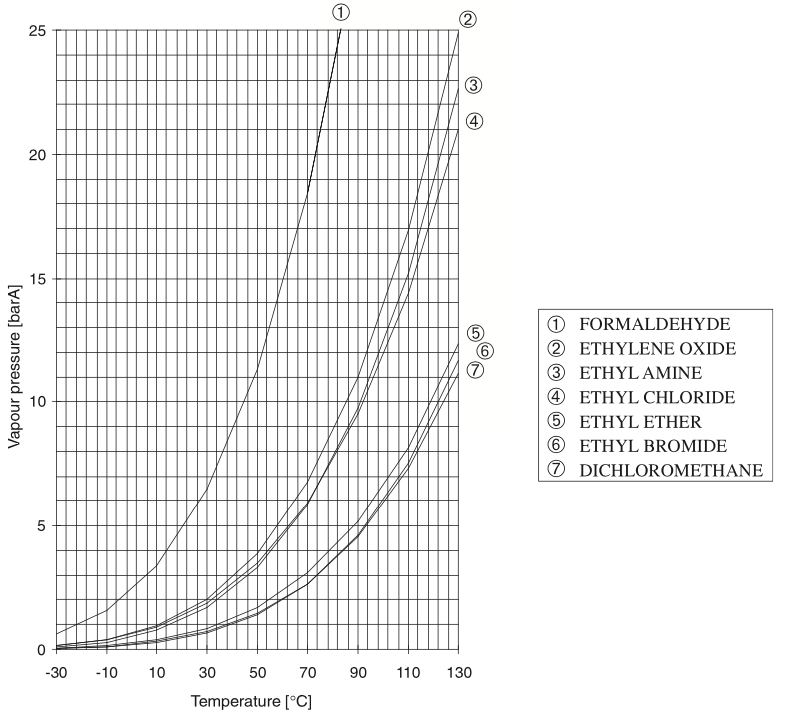

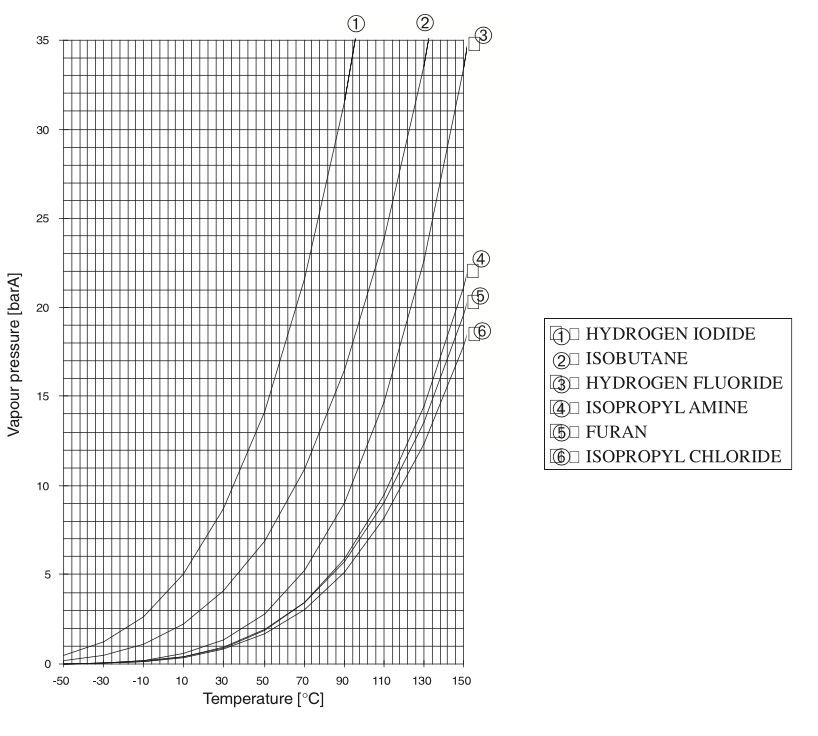

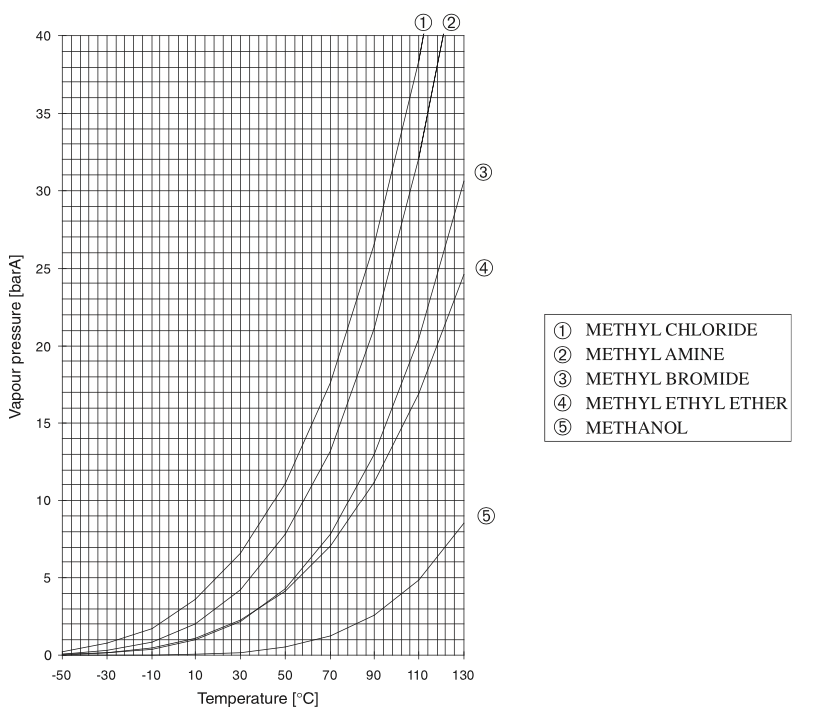

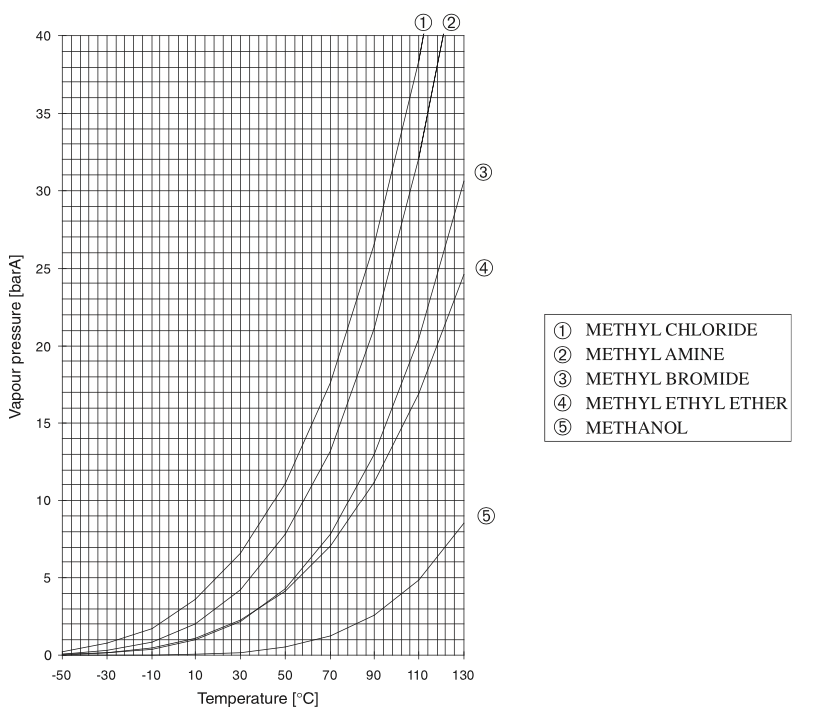

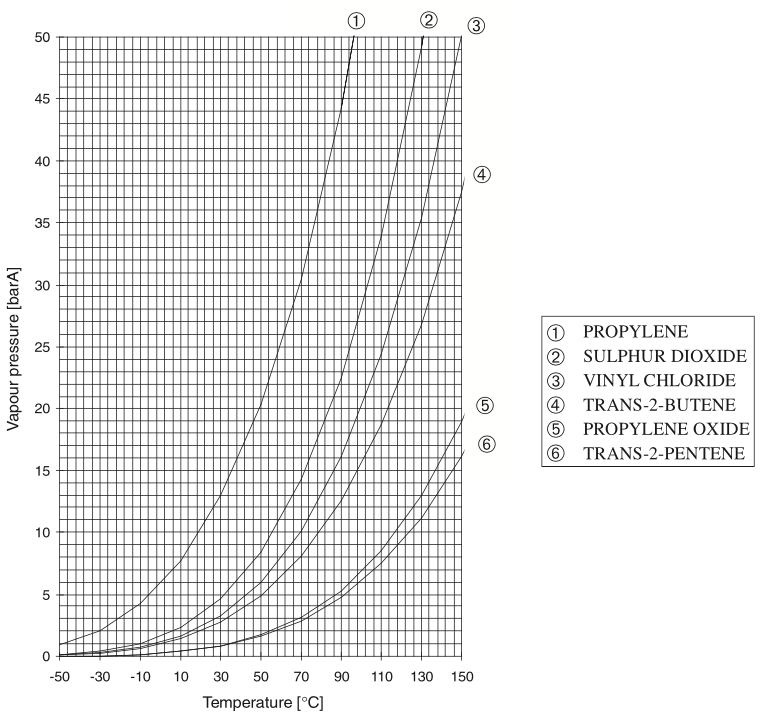

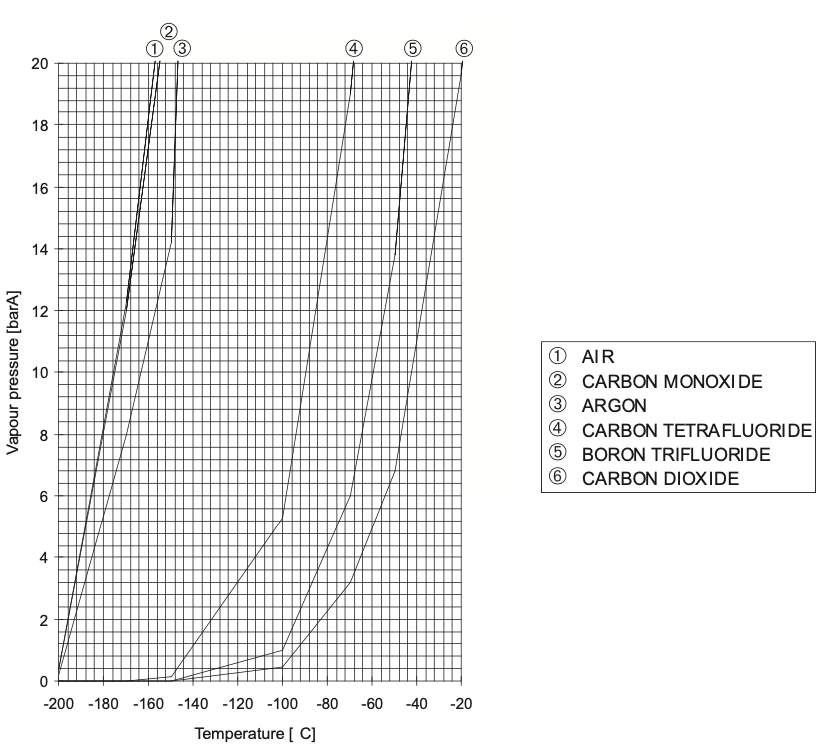

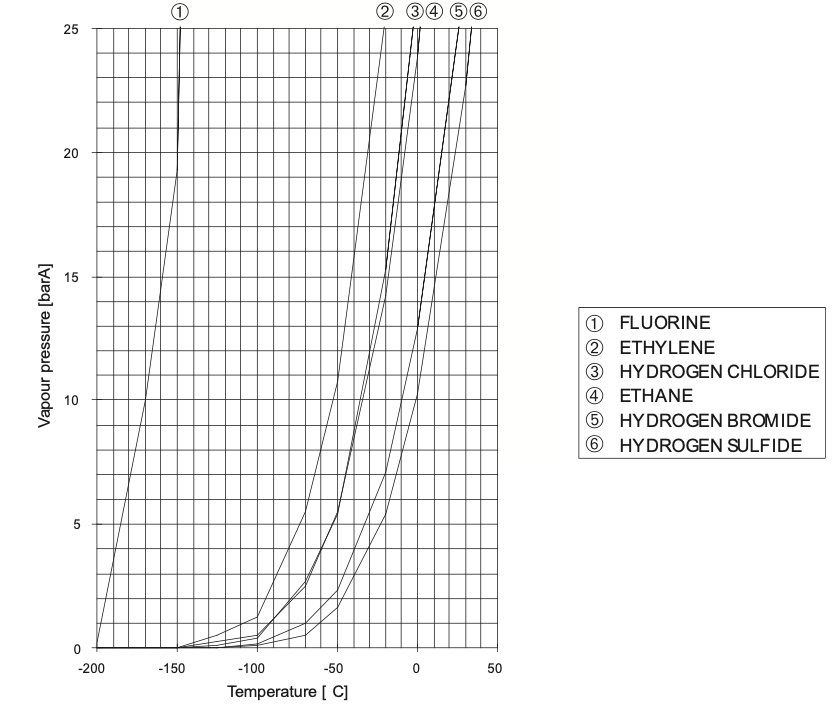

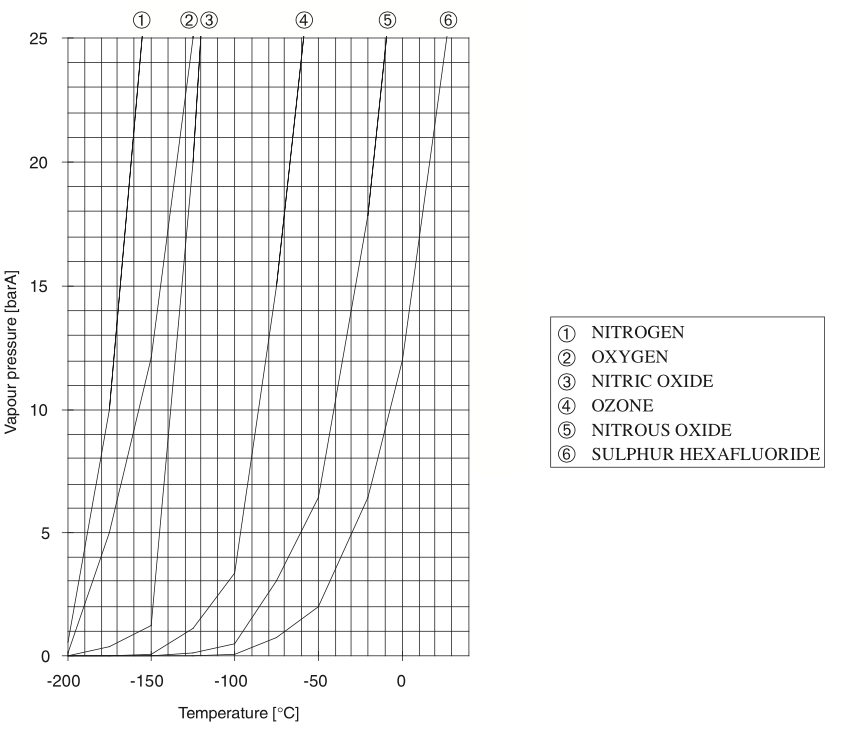

F Vapor pressure curves

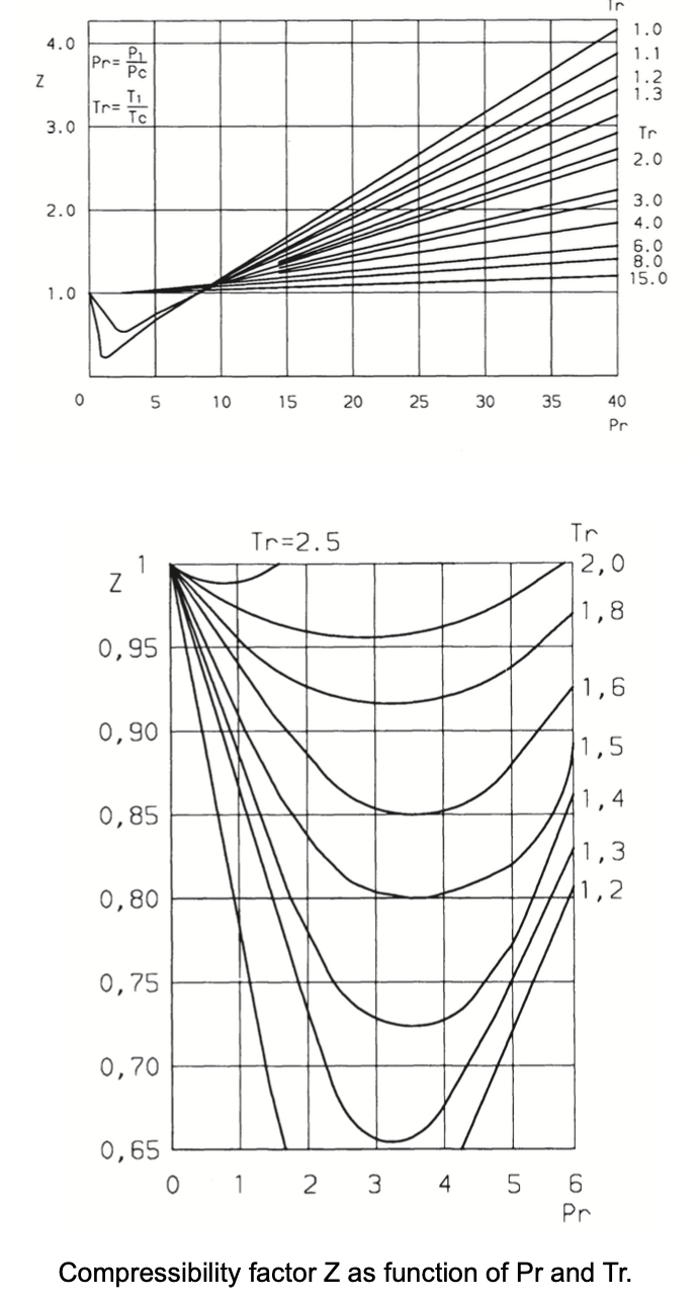

G Compressibility factor z

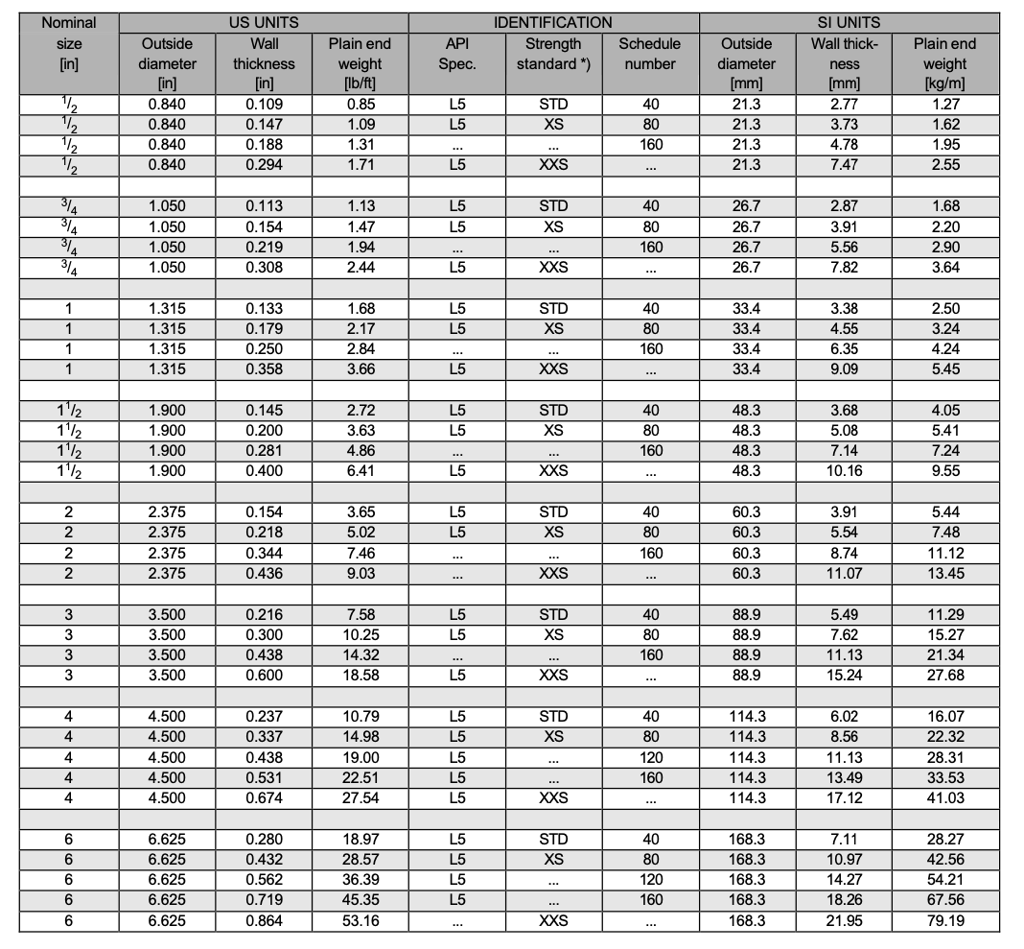

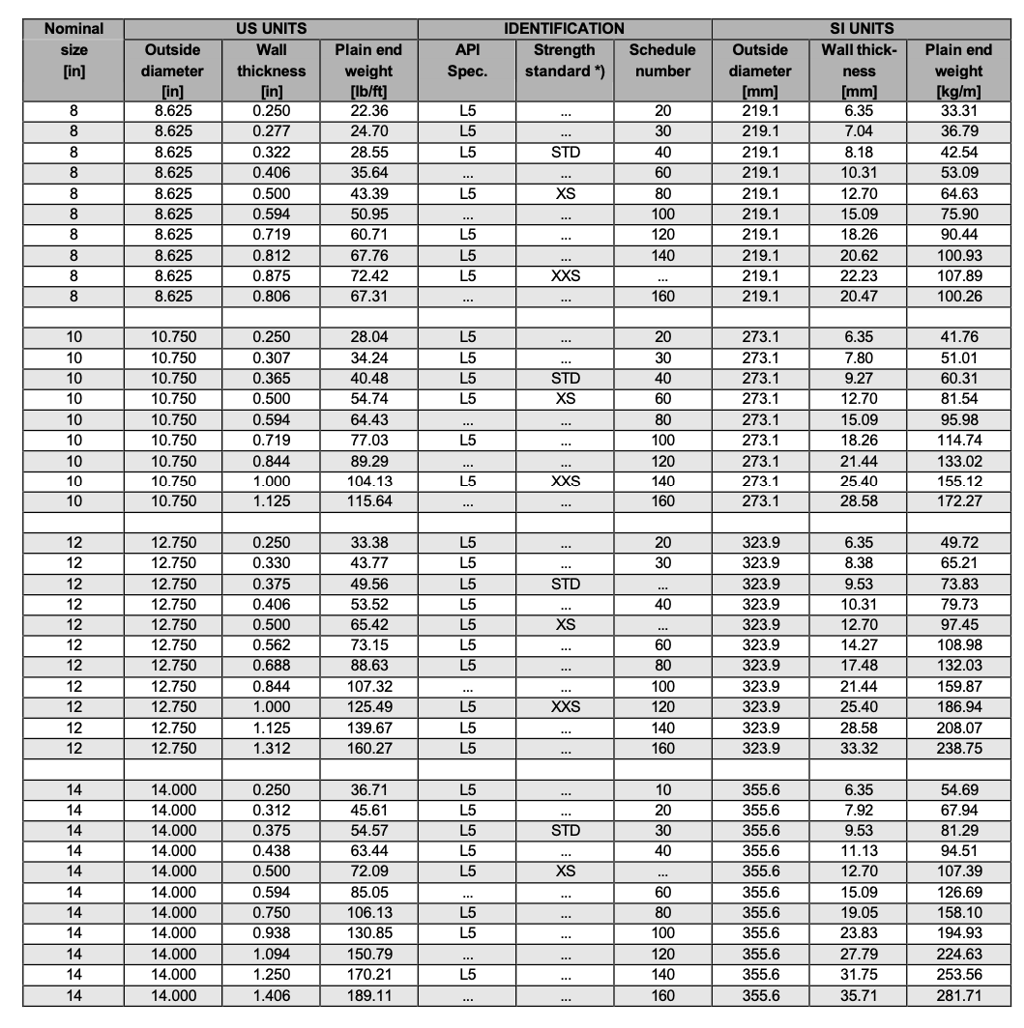

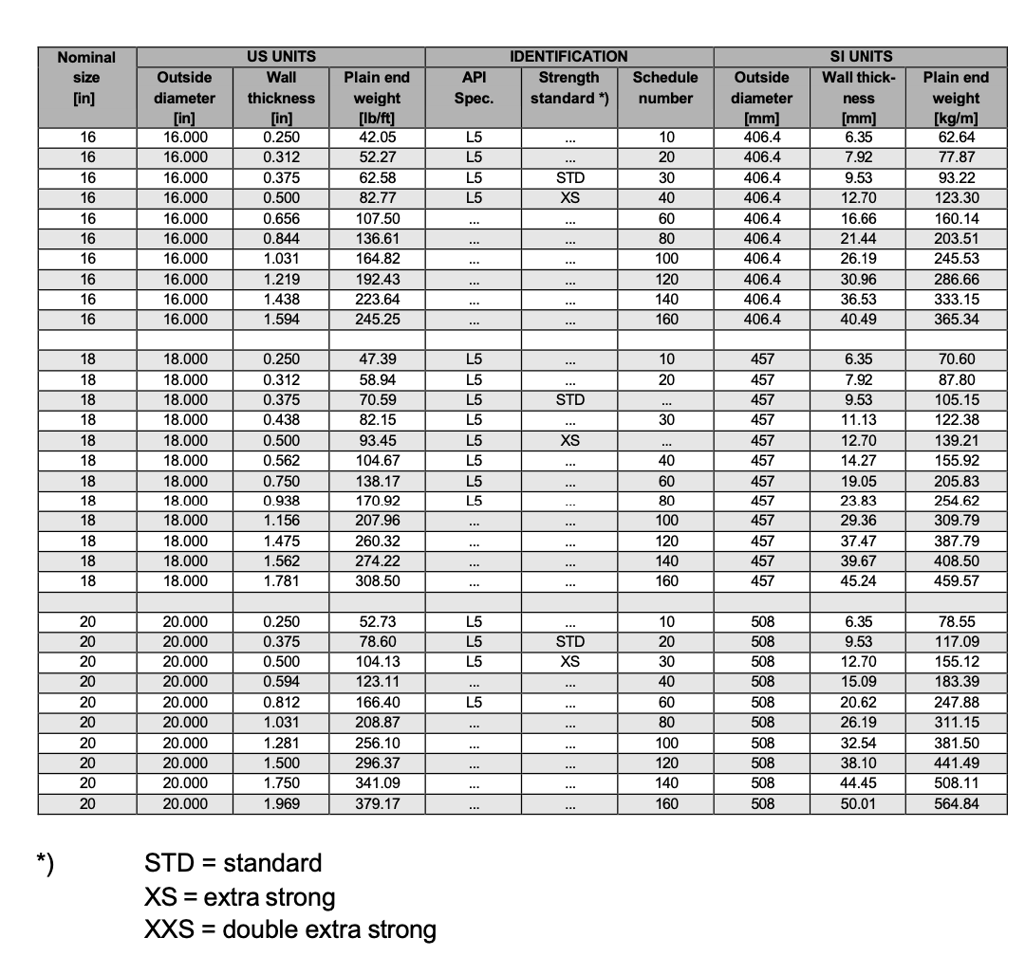

H Pipe tables

Dimensions and weights of most common welded and seamless wrought steel pipe based on ANSI/ASME B36.10M standard.

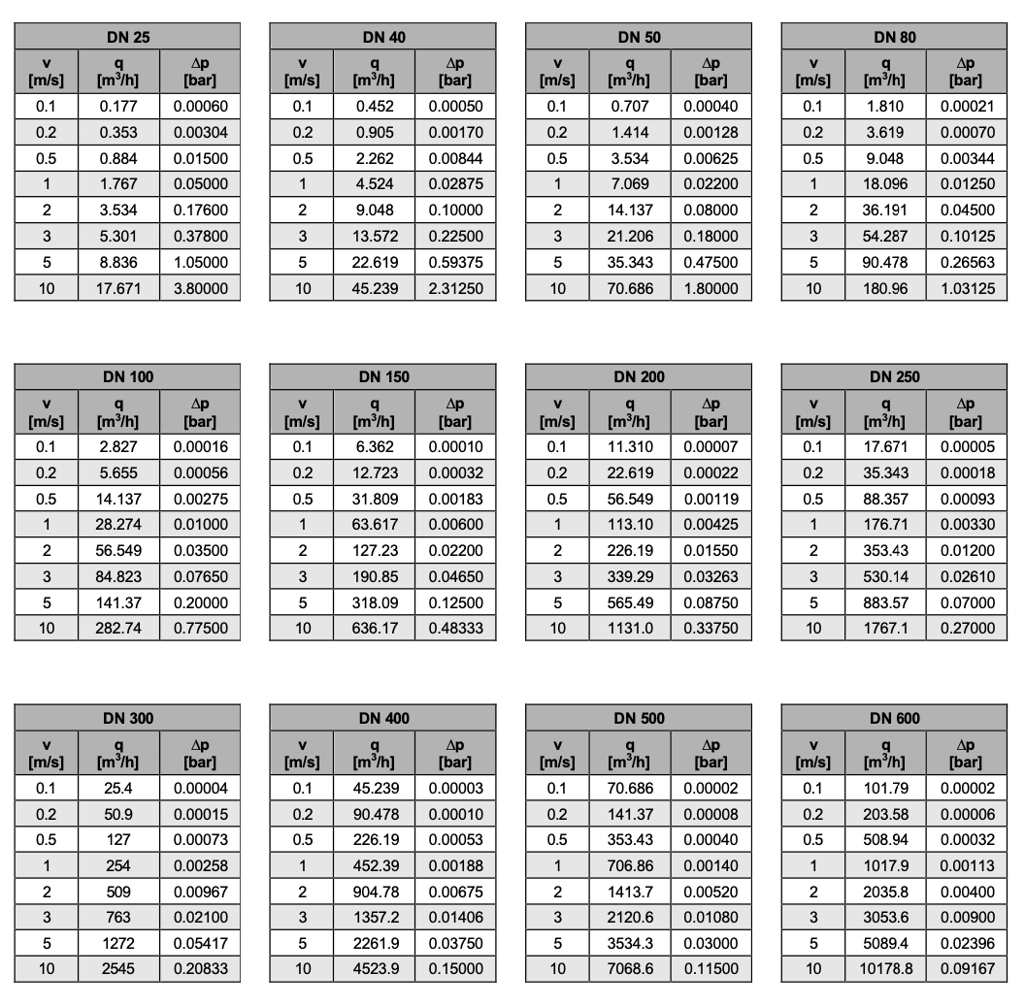

I Pressure drop in steel pipes

Pressure drop (∆p) of 20 °C water per 10 m length of new commericial steel pipe with varios pipe internal diameter (DN) and velocity (v) or flow rate (q).

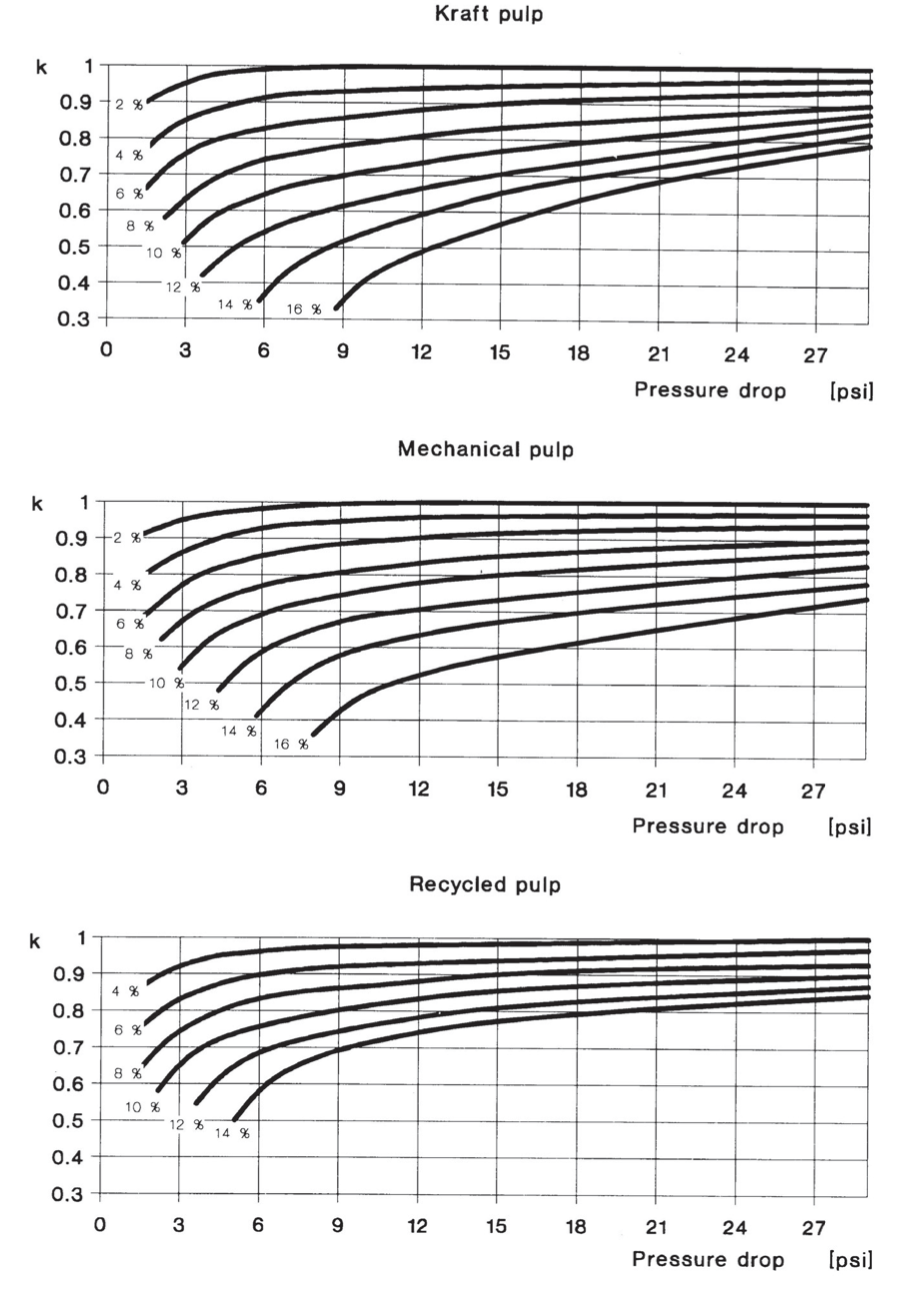

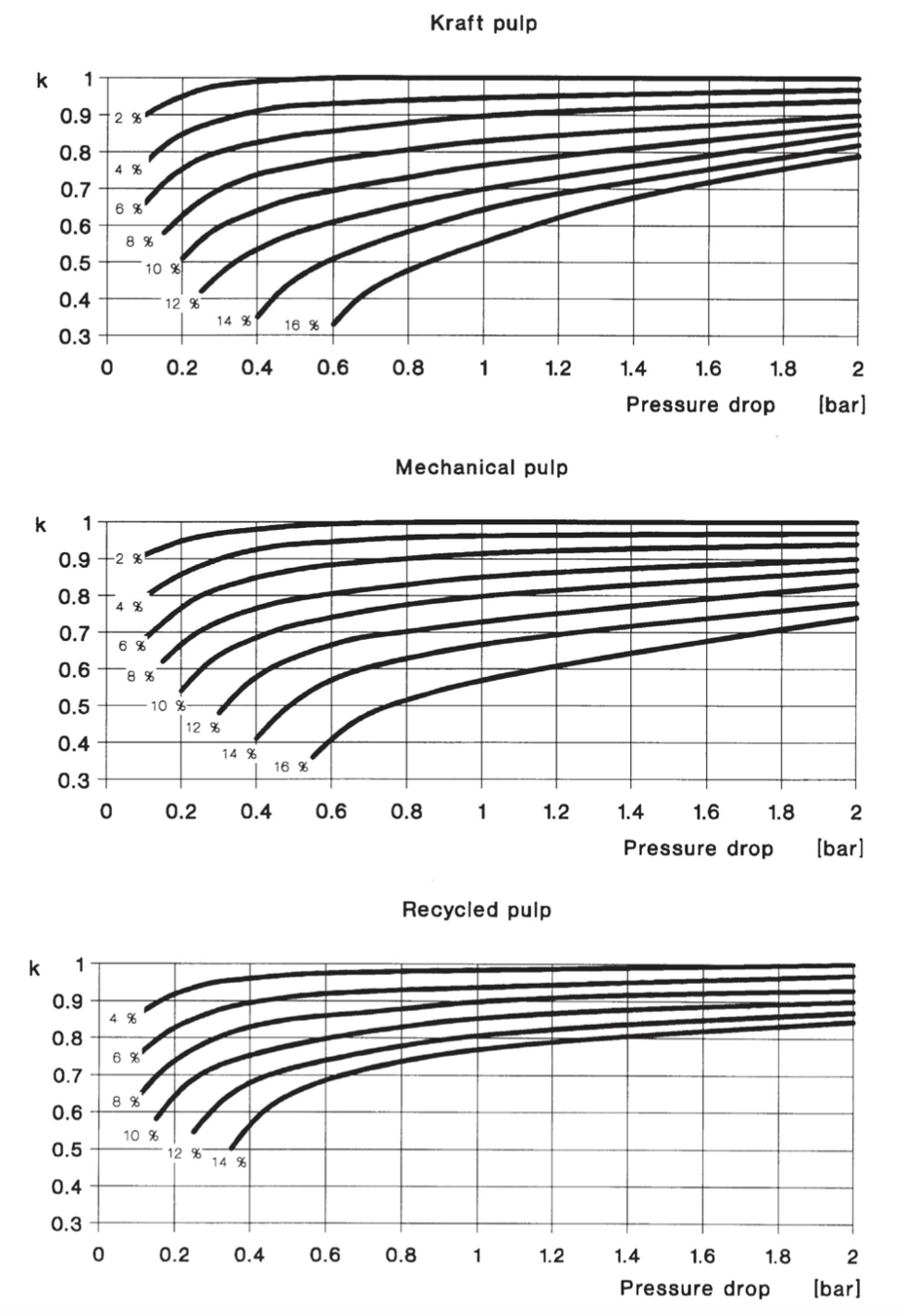

J Correction coefficient k for pulp flow

Correction coefficient in SI units.

K Noise prediction aspects

In control valve sizing calculations in this flow control manual, the practice is to use IEC/ISA sizing methods. The valve noise level calculation method presented, however, is based mainly on the VDMA 24422 (version 1979) and IEC 60534-8 standards. The calculation procedure presented here covers only the noise generated by the dynamics of flow within a closed piping system, whereas mechanical rattling, transmitted noise amplification caused by reflections and/or resonances are excluded. The calculation procedure is based on sound pressure level measurements carried out using a standardized test arrangement. The microphone position is 1 m downstream from the valve outlet, and 1 m from pipe surface. The calculations are valid for a straight uninsulated pipe in an open environment. The noise calculation equations are verified by experiments. Therefore, owing to the large number of factors influencing noise level, the accuracy is within tolerance band of up to 10 dB(A).

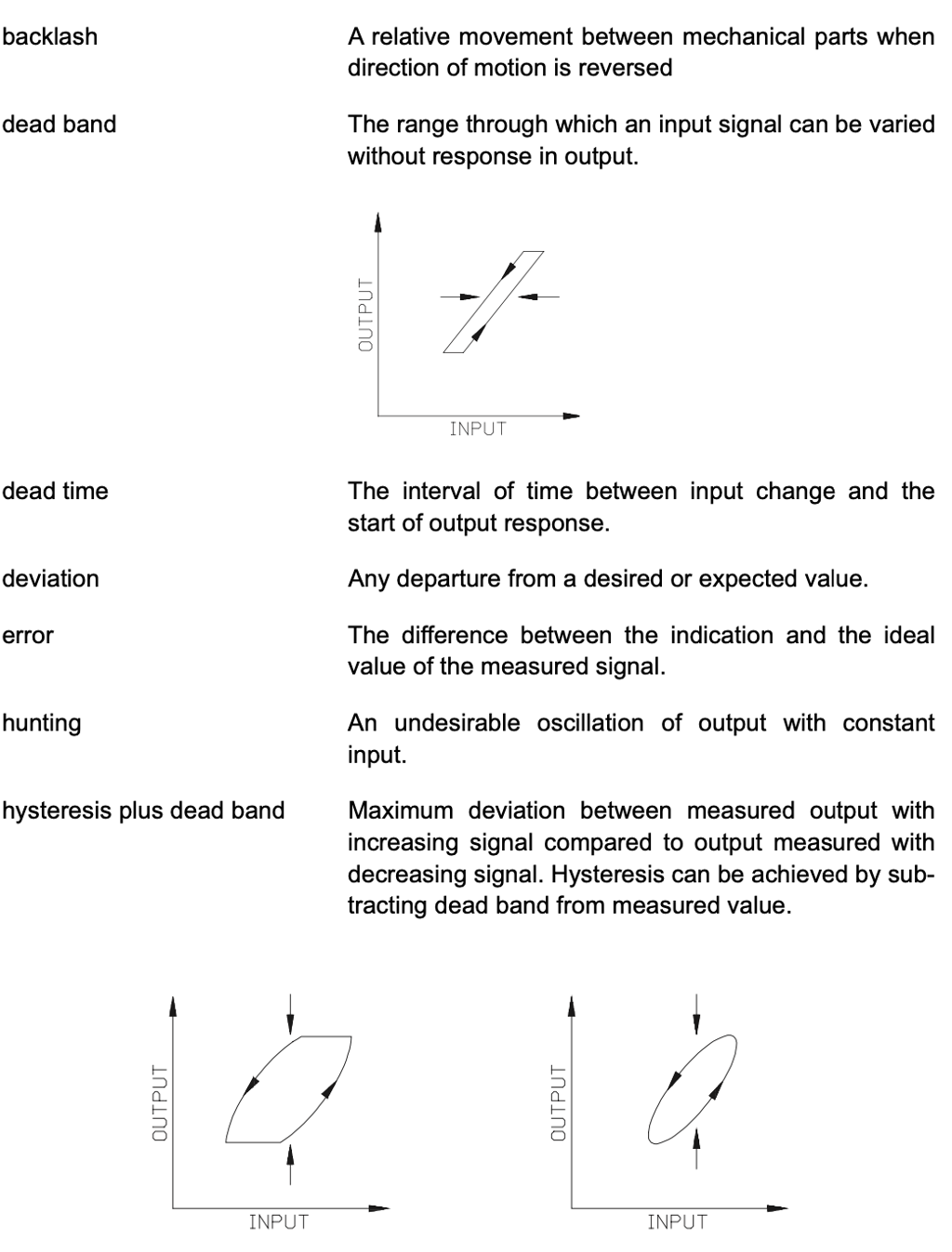

L Control valve performance terminology

M Manifold design guidelines for valves

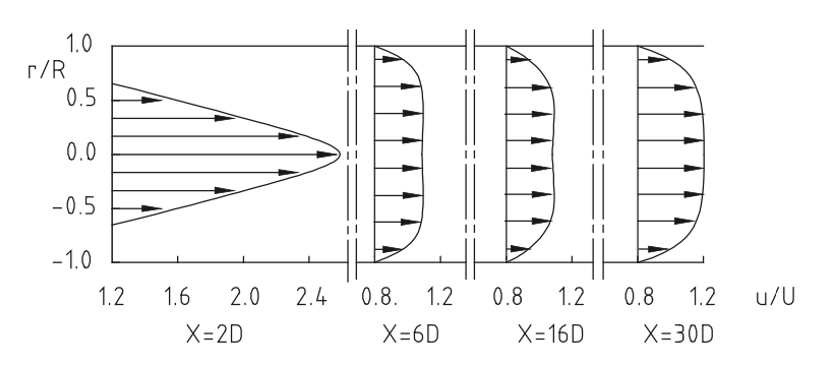

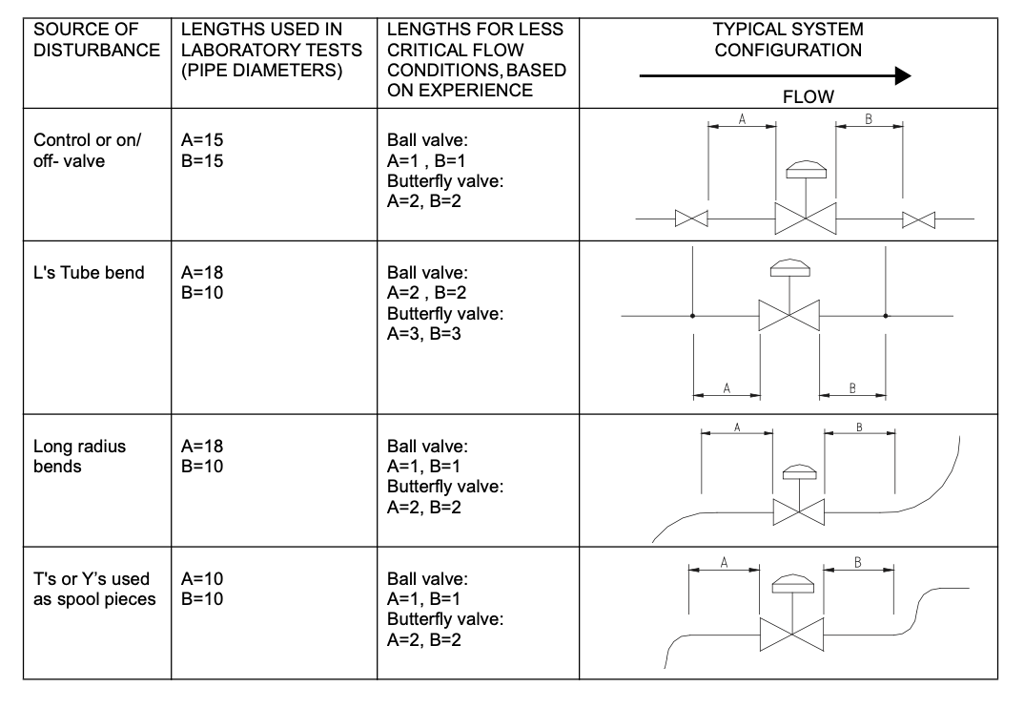

Different components in process piping cause disturbances in the flow pattern. Pumps, joints, elbows etc. are all components that may affect the performance of a control valve. These disturbances must be taken into account when control valves are selected. If maximum capacity is required, it is recommended that valves are installed in the pipe line with enough straight pipe upstream and downstream of the valve to ensure constant velocity profile distribution. Some examples of possible disturbances to the flow pattern are given below.

Since every case is individual there are no universal rules for manifold design, but the following pages contain some information about the subject. The designer should always remember that control valve applications are usually designed individually, using detailed data for each case.

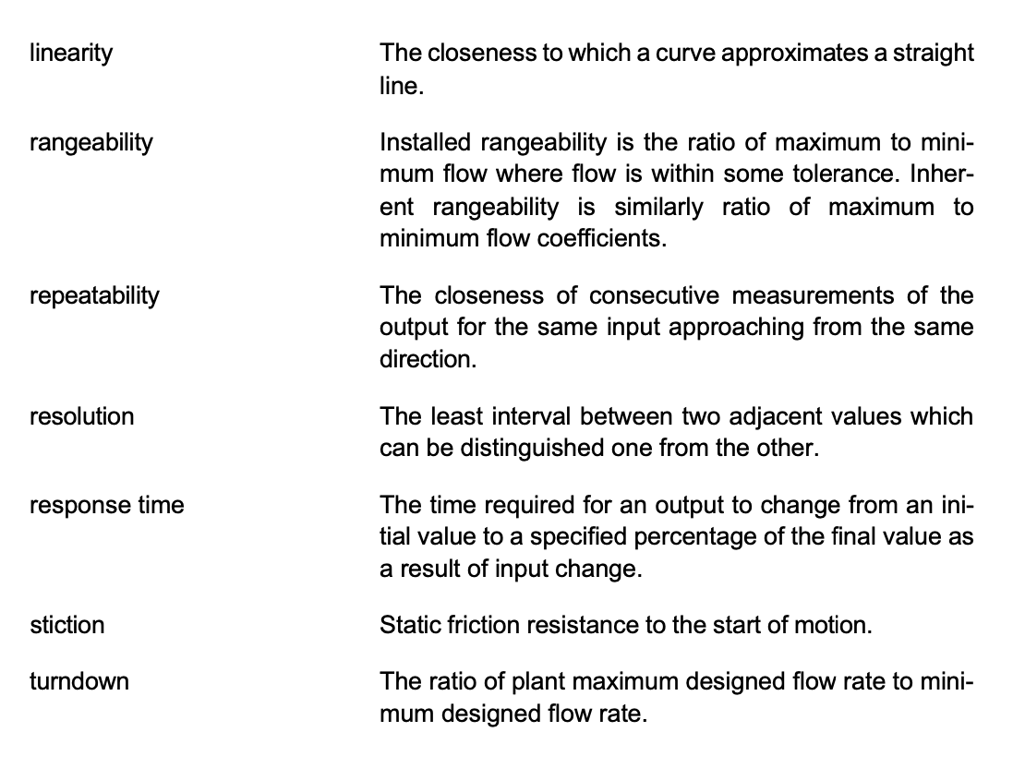

Figure 1. Velocity profile distribution after an orifice at different distances

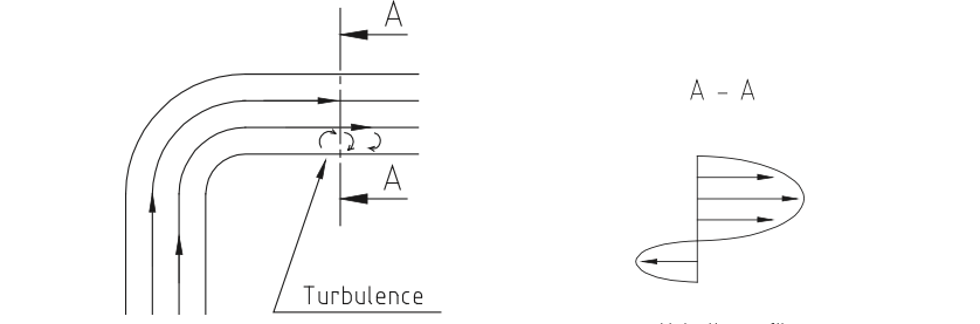

Figure 3. Flow pattern in a 90o bend. Where the turbulence is heavy cavitation may occur.

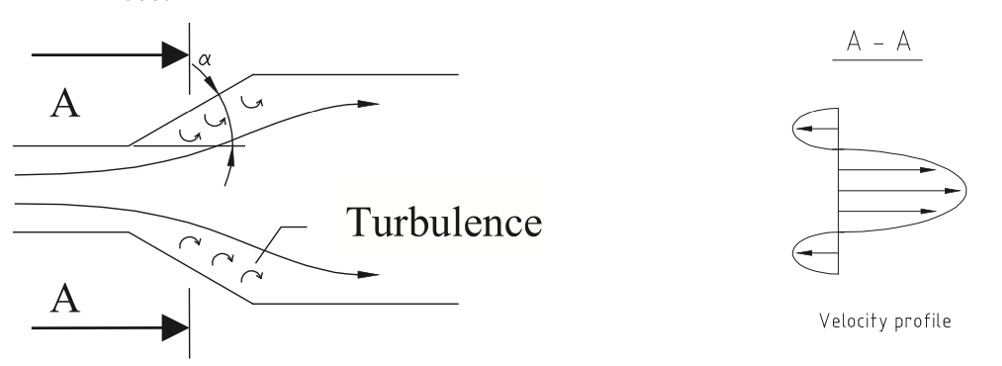

Figure 4. Flow pattern in an expansion piece.

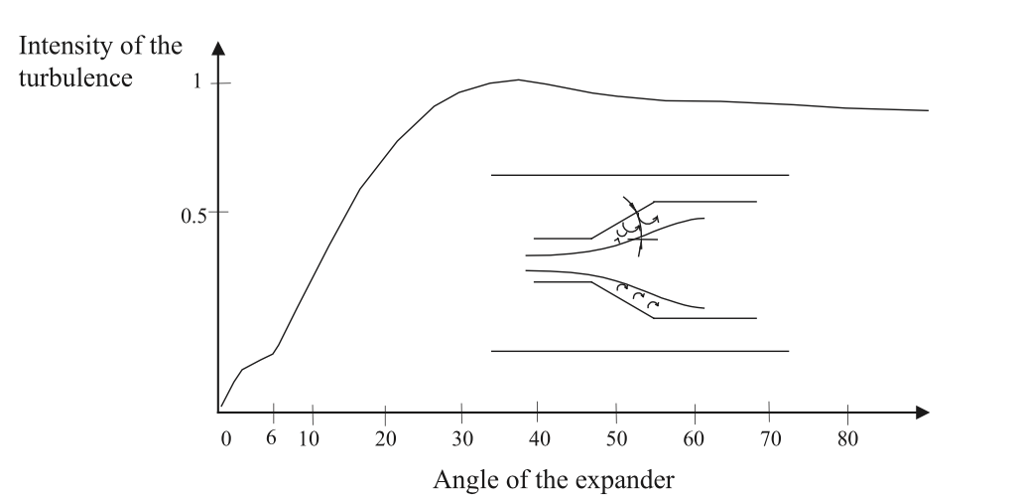

Figure 5. The intensity of the turbulence in an expansion piece depending on the angle.

(As the angle becomes greater, the intensity of the turbulence increases rapidly.)

As can be seen from the examples above, it is important in pipeline design to try to avoid an assembly that combines, for instance, a 90° bend just before a butterfly valve. In the case of liquid flow there could be problems with cavitation in the bend, causing noise and damage. Disturbances from a bend can also affect the performance of the control valve. Usually the effect on the maximum capacity is insignificant, especially when the control valve is installed with pipe reducing and expansion pieces as is usually the case. The cavitation features of the valve can also change.

Particular points that should be taken into account in manifold design for butterfly valves:

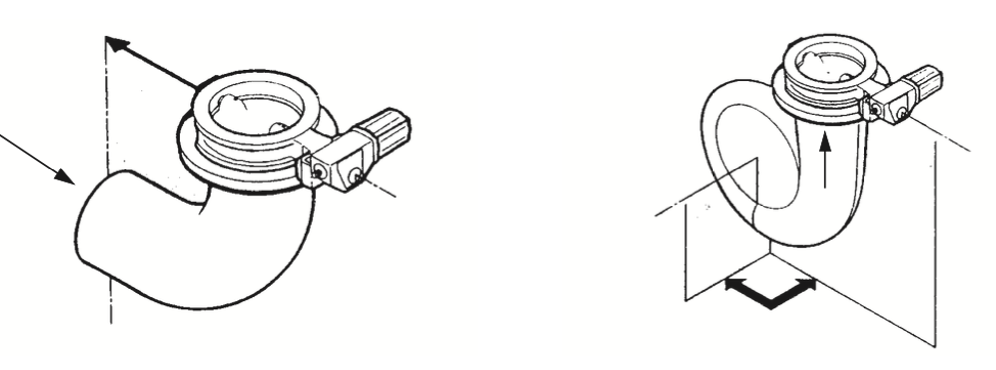

Figure 6. The installation direction of a butterfly valve after a bend or a centrifugal pump.

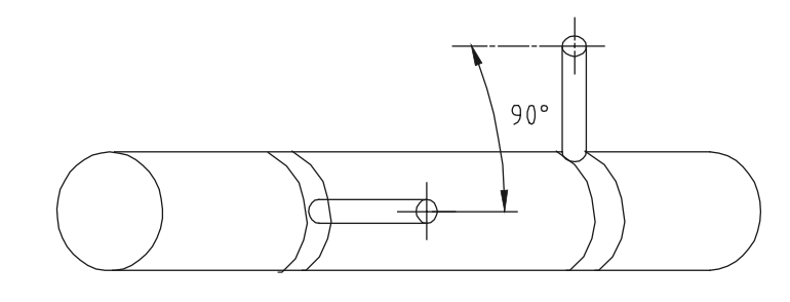

Figure 7. If two butterfly valves are installed in series, their shafts should be at a 90° angle to each other.

Figure 8. Installation of baffle plates, orifice plates and attenuator plates.

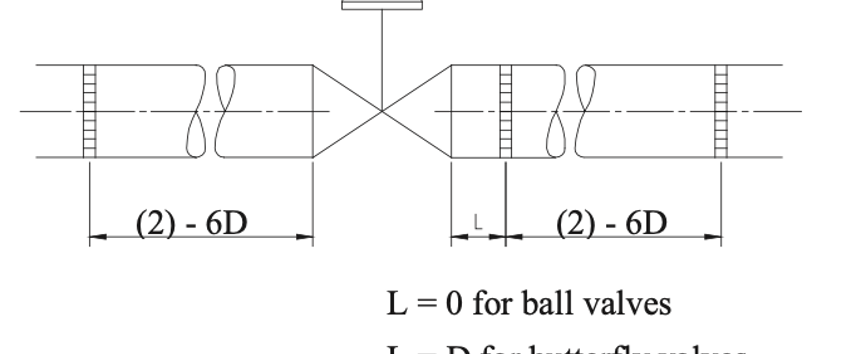

To ensure optimum performance from the valve, the following guidelines should be followed. This will ensure the valve behaves as predicted. In practice, however, millions of valves have been installed in all kinds of piping configurations without any problems. This is because, in most cases, the accuracy of the flow data actually contributes more to the control valve sizing accuracy than any of the issues described above. Thus the table below can be used as a guideline for building accurate laboratory equipment, but for a typical flow loop in the mill, these instructions are not critical.

The affect of the reducing pieces just before and after the valve are taken into account when the valve is sized with, for instance, the control valve sizing and selection program 'Nelprof'.

Sooner or later, the designer faces a situation where he must compromise on manifold design. It may not be possible to have enough straight pipeline. In such cases the designer has to consider the complete installation. Are the velocities high or low, is the pressure high or low? With high velocities and low pressure it is more important to try to avoid complicated manifold designs. If the control valve is very close to cavitation point, it is a natural solution to extend the straight pipeline downstream of the valve. It is always worth investigating whether the valve could be relocated etc. If the capacity of the control valve is at its upper limit, it is important to ensure a constant velocity profile at the valve inlet. This can be achieved with sufficient length of straight pipe upstream from the valve. These are the kind of things that the designer should consider before the final layout is decided. As a rule of thumb, it can be said that the easier the case, the greater the compromise that can be made with manifold design and still maintain control valve performance at the desired level.

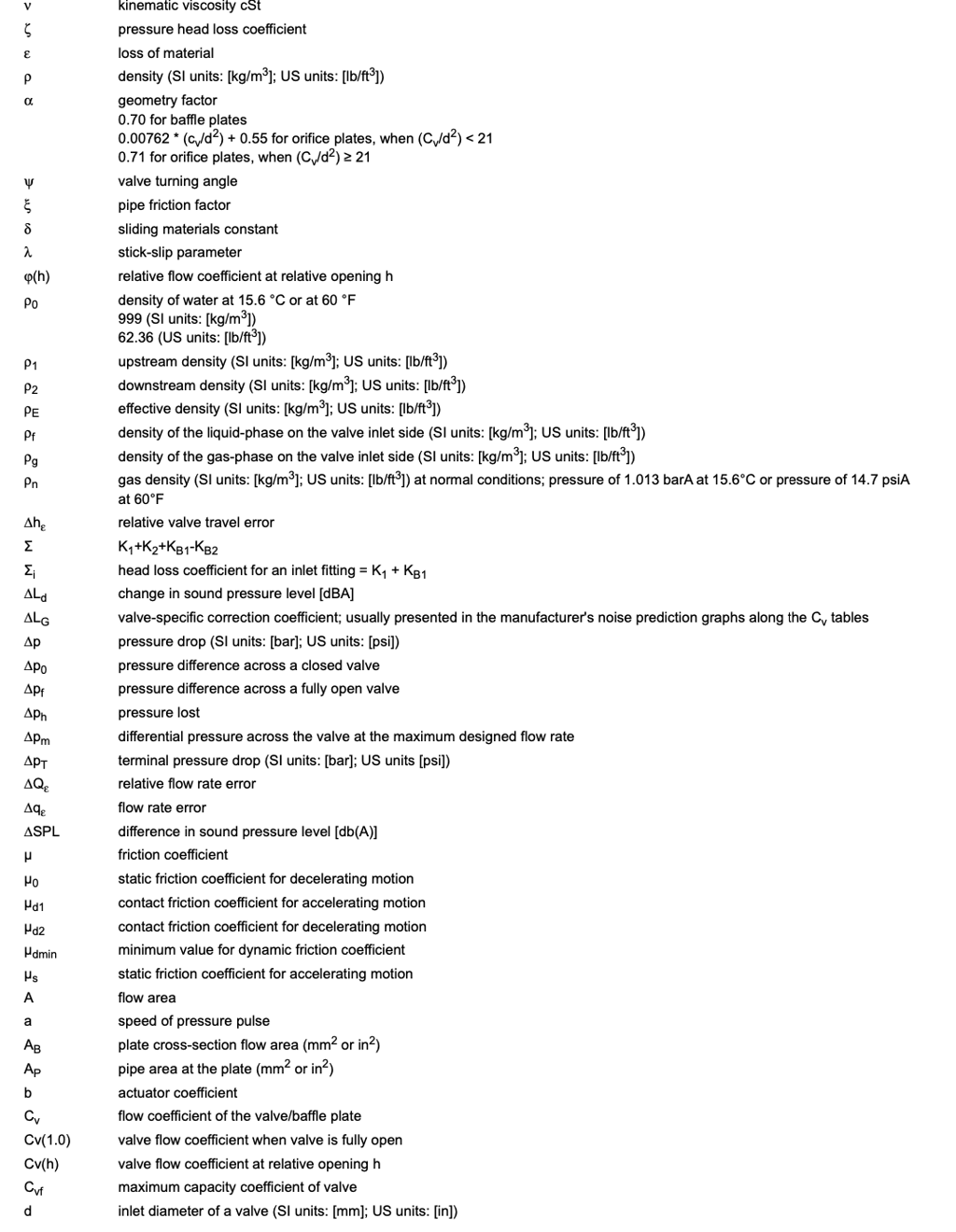

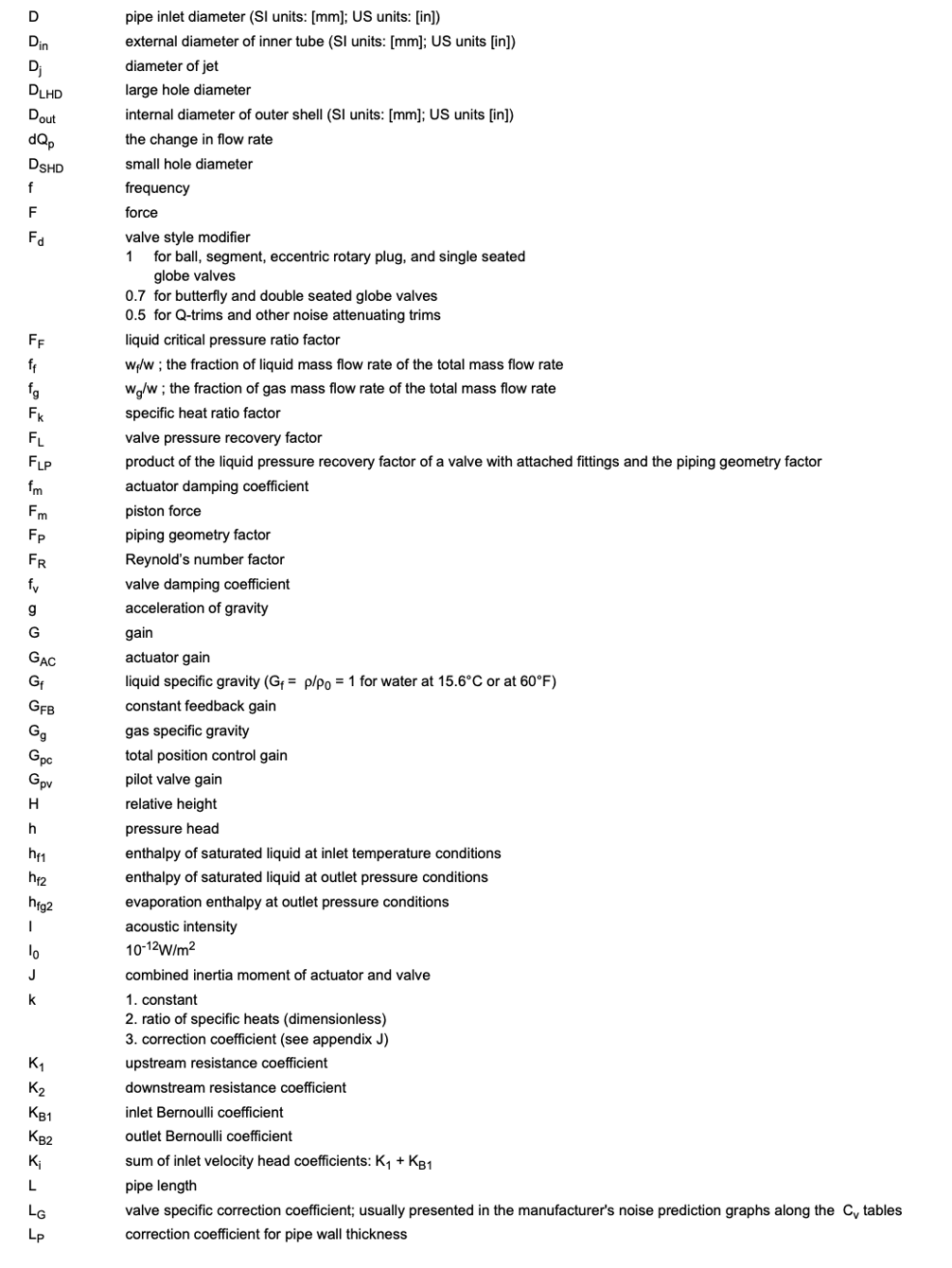

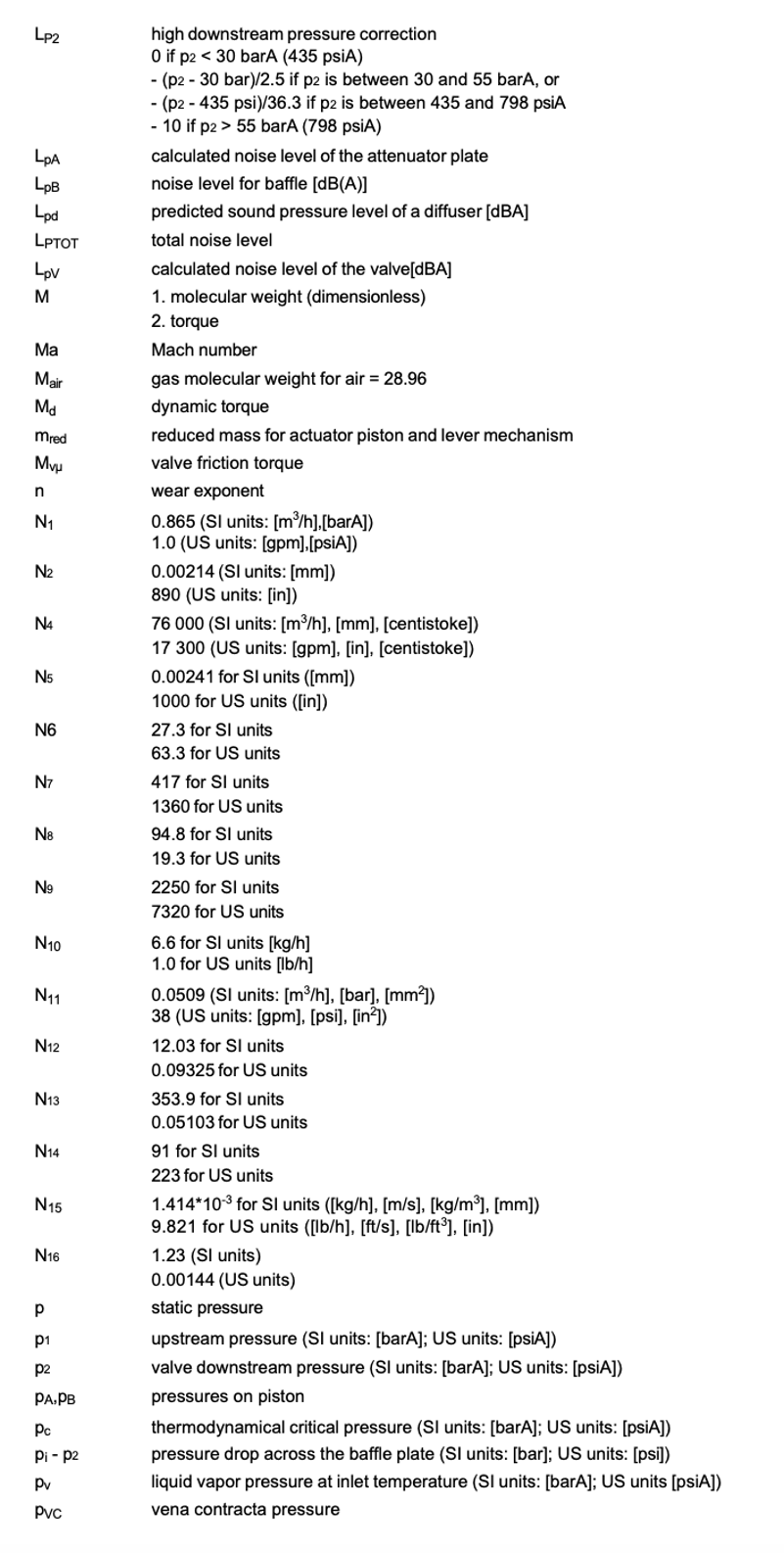

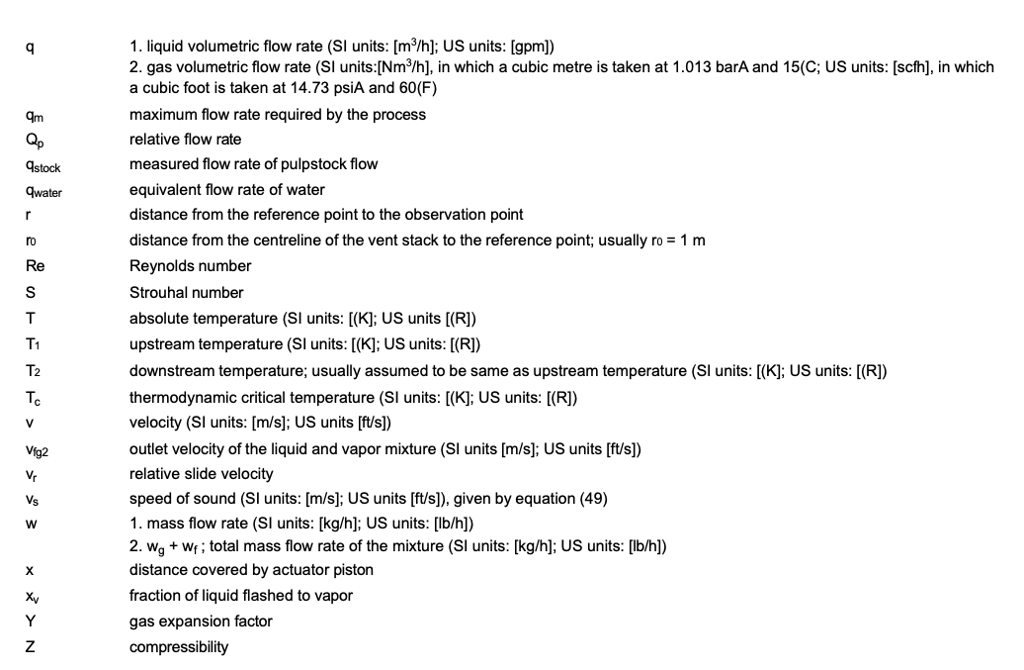

List of symbols