Custom Metal Fabrications

Laser, High Definition Plasma, and Water jet cutting

The pulse of the Service Center runs through the automated high speed, high accuracy Laser, High Definition Plasma, and Flow Jet cutting machines.

CNC Metal Bending Services

Valmet has a broad range of metal bending capabilities to form various steel shapes and thicknesses of steel. Expansion joints, Handcuff’s, wall boxes, seal plates.

- Machines ranging from 175 ton to 1000 ton

- CNC automated steel bending

- High precision and quality

Welding Services

Valmet is always prepared to manufacture your customer parts on short notice. Our certified welders can weld and create custom subassemblies of piping, plate and structural parts.

- Manual Stick Electrode (SMAW)

- Manual TIG (GTAW)

- Semi-Automatic MIG (GMAW)

- Semi-Automatic Fluxcore (FCAW)

- Mechanized Submerged Arc (SAW)

- Automatic Stud Welding (SW)

Process Information

| Engineering & Design Capabilities | Valmet Engineers can design and enter part specifications into SolidWorks allowing them to move from 2D to 3D CAD with ease, ensuring that each steel part is cut to the same exacting specifications and precise dimensions. SolidWorks 3D CAD software allows for accurate 3D models that automate a full range of design and development processes, reducing costs, and improving product quality. This expedites production and increases reliability through use in all of productions CNC and Laser Cutting applications. |

| Welding Certifications |

ASME Code Stamps:

Inspectors CWI certified |

| Crane Capacity |

Valmet has the ability to fabricate large weldments with crane capacities of 7.5 Ton up to 40 ton, and 25’ under hook floor clearance. |

| Tooling Inventory | Valmet holds a large supply of machine tooling in stock. A broad range of tooling provides for fast and efficient turnaround services to our customers. Please note: Longer lead times are expected with specialty tooling requirements. |

| Stainless Steel Inventory | Valmet has an extensive inventory in sheet, bar, and welding materials maintained for heat resistant, corrosion resistant, and high temperature alloys. All products are purchased to proprietary customized specifications as well as normal industry standards with supporting documentation. The ability to obtain mill direct pricing and consignment inventory control has enabled our team to provide competitively priced products and control delivery of projects. |

| Preferred Drawing Submission |

PDMS, AutoCAD, and SolidWorks, |

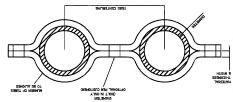

Custom tube alignment bar information

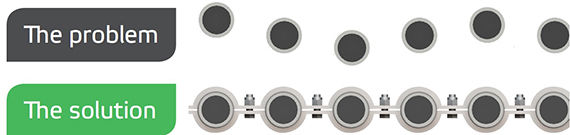

Over time, expansion, contraction, and vibration associated with soot blowing and general boiler operation can cause misalignment and bowing of tubes in various areas of the convection pass in your boiler. This can leave the tubes susceptible to erosion or corrosion damage, as well as create heat transfer imbalances that are detrimental to the long-term serviceability of these tubes. Improper tube alignment can also contribute to boiler fouling and draft loss, resulting in increased fan power consumption and possibly even boiler down time.

Tube alignment bars have proven to be a cost effective means of holding misalignment and bowed tubes in their proper position, thus avoiding problems that can adversely affect boiler operation or shorten the service life of the tubing.

Valmet has manufactured tube alignment or “handcuff” assemblies for all types of boilers and boiler environments. Because we are the leading supplier of tube shields for the power industry, our extensive high temperature material inventory and tube radius die sets facilitate production of virtually any handcuff assembly arrangement. This can be done in a timeframe that meets your demanding outage schedules.

Alignment bars

Availiable as bolt in (shown above) or weld in type

Please fill in the contact form below so that we can provide you with a quote. If you don’t have all the information, just give us a call and we’ll help.

(Fields with an * are mandatory fields)

For more information on our privacy practices and how we are committed to protecting your privacy, please review our Privacy Notice.