Greenpac PM 1: remote support solved energy consumption increase in dryer section

As a part of continuous remote monitoring & optimization service Valmet Performance Center supported Greenpac remotely to identify and solve energy consumption increase issue in the dryer section.

Summary

As a part of continuous rem As a part of continuous remote monitoring & optimization service, ote monitoring & optimization service,

|

Location |

Greenpac, Niagara Falls, United States |

|

Solution |

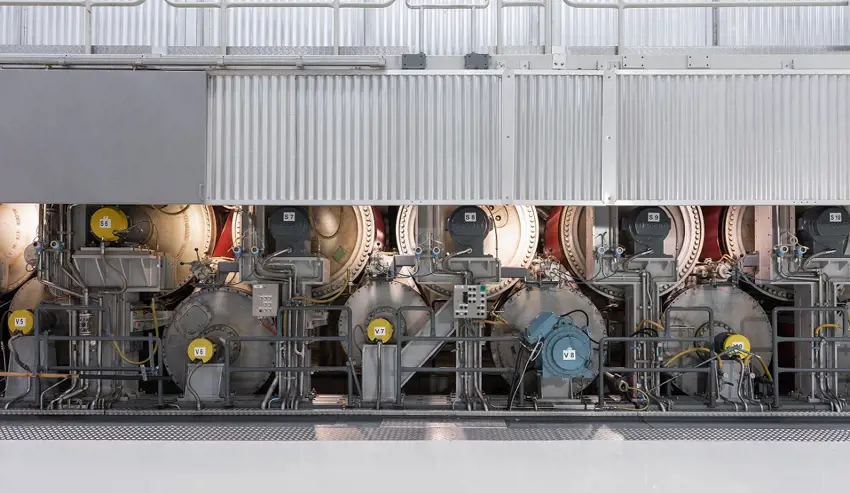

As a part of continuous remote monitoring & optimization service, Valmet Performance Center (VPC) proactively noticed a remarkable (50%) energy consumption increase in the seventh dryer group. The increase in energy consumption was not in the beginning continuous, but with certain grades the energy consumption always increased. Customer and VPC together conducted checks and tests to identify the root cause for this. Dryer can internals were identified as one possible key issue. Customer inspected the dryer can and a worn-out siphon tube was discovered. The damaged siphon tube caused the condensing water to build up in the dryer can which led to the increased energy consumption. Customer replaced the damaged siphon tube and the energy consumption returned to normal level. |

|

Results |

Due to continuous monitoring & optimization services a 50% (from 200 kW to 300 kW) energy consumption increase was noticed very early on. In the long run this resulted in energy and cost savings for the customer. In addition, The structures and drive train were also spared from additional mechanical stress due to the water load. |

|

Keywords |

Valmet Performance Center, Industrial Internet, remote monitoring and optimization |