Gold East Paper Jiangsu improved shipping roll quality with the 100th iRoll Portable

With annual capacity of almost 2 million tonnes, Gold East Paper Mill is one of the leading manufacturers of coated woodfree papers. Valmet teamed up with the mill and performed parent roll hardness profile optimization with iRoll Portable technology.

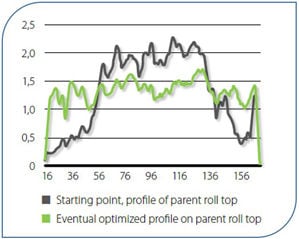

Optimizing the parent roll structure was easy as the results could immediately be seen from the iRoll Portable online data. The green graph above illustrates the improved hardness profile at the top of the parent roll and the grey graph shows the starting point.

iRoll Portable is a solution for quick and cost-efficient nip or process analysis and tuning with a temporarily installed iRoll system. iRoll Portable runnability analysis for reels, winders, web tension profiles and fabric tension profiles is performed online during production as the target is paper quality, runnability and parent roll hardness profile improvement.

Summary

| Location | Jiangsu, China |

| Customer challenge | The aim was to find tools for the best possible runnability and roll quality in winding. |

| Solution | iRoll runnability analysis was initiated in order to study parent roll hardness profiles and to find out reasons for possible profile variation and skewness. |

| Results | New practices for performing off-line multinip calender profiling were learned to remove the hard edges on parent roll bottoms and soft edges on top. Optimized profiling contributes to even better customer roll quality and winder runnability. |