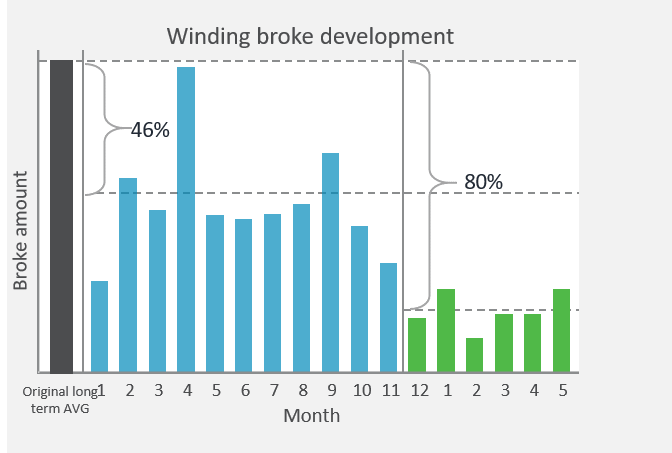

80% less winding broke with iRoll

Sappi Alfeld mill, PM 2 has a complex process of producing wide mix of specialty paper products. They have a strict tolerance towards defects in shipping rolls which led to high amount of winding broke.

SUMMARY

| Location: | Sappi Alfeld mill in Germany |

| Customer target: |

Sappi Alfeld focused on production efficiency. They set the quality standard high, only rolls with a perfect appearance and profiles would be accepted. At the same time material efficiency must be improved. |

| Solution: |

First winding broke was decreased with manual hardness profile optimization and by using iRoll Portable. For better results iRoll Reel hardness profile control with a soft Valmet Reel Drum Cover RS was installed on the reel. Also Valmet IQ CD Controls multivariable profile controls system was taken into use. |

| Results: | Profitability improved, mill met the requirements for high speed, top product quality, a wide product mix and excellent material efficiency. |

Technical data

| Grades: | Specialty packaging and label grades |

| Basis weight: |

Ranging from 50 to 180 g/m2

|

| Wire width: | 5,150 mm |

| Production speed: | 1,200 m/min |