Designed to meet tissue producers’ challenges

All tissue machinery solutions

Moving your production forward

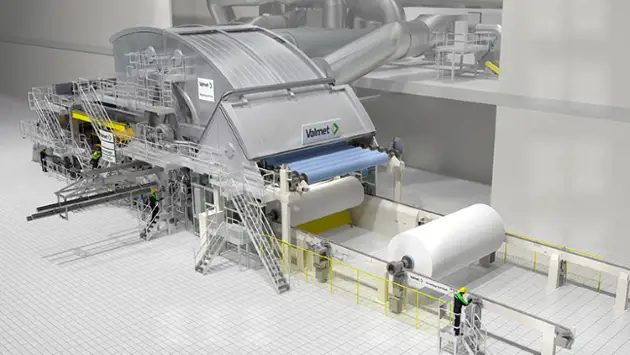

Selecting a tissue machine from the Valmet means more than just a purchase. It's the beginning of a long term collaboration where we are with you all the way throughout the lifecycle from mill engineering, installation, start-up to service, maintenance and upgrades.

Valmet is the leading supplier of the entire tissue making process and have the flexibility to meet the requirements of all tissue products. Our technologies meets the specific customer needs based on sustainability and desired paper properties. Our design philosophy is to utilize our vast experience from executed deliveries combined with our pilot facilities to be in the forefront when it comes to deliver sustainable results.

Our working method is built on close collaboration with you as a customer. Together we define the challenges and develop the best solution for your actual requirements.

Finding the right concept

Our experts can support you in the selection to find the most suitable concept for your production needs

Get in touchConventional dry crepe concepts

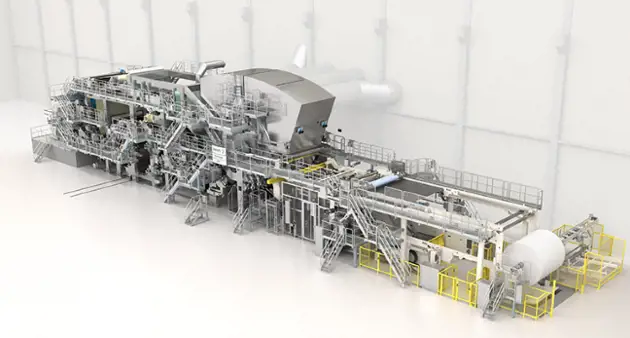

IntelliTissue concept is in the front line of small and medium sized tissue machines with proven crescent former technology combined with low media consumption. The conventional Advantage DCT machine has become a trademark for production of plain or conventional tissue products with high quality. It is a cost-efficient and sustainable process in regards of low energy- and water consumption, high efficiency and capacity. The concept is available in various models and sizes to fulfill each specific quality and production demands.

Explore more

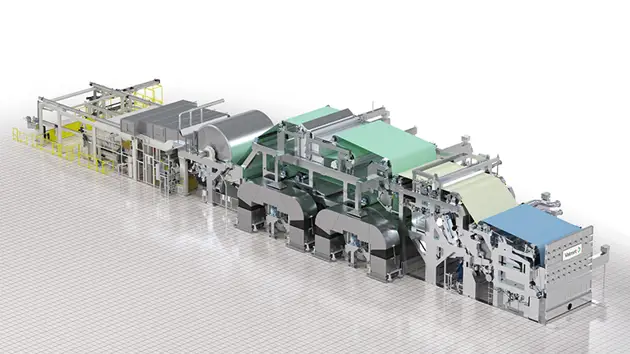

Hybrid concepts

When looking for maximum flexibility the hybrid concepts can be your choice. With the capability to produce plain and textured tissue with premium quality at low energy and fiber consumption, Valmet’s Advantage technologies meet the increasing market demands of products with high absorption, bulk and softness at the same time as it provides a sustainable process and low energy consumption.

Explore more

> Advantage NTT technology concept

> Advantage QRT technology concept

> Advantage eTAD technology concept

Through Air Drying concept

For more than 40 years, Valmet has been designing and building Through Air Drying (TAD) machines for the tissue industry, becoming an industry leader. The Valmet Advantage Thru-Air process is the right technology to use for reaching the highest level of quality while using less fiber compared to any other process on the market. The technology is adaptable for using multiple sources of energy and for recovering of process equipment, which is important to reduce the energy consumption and impact of the process on emissions.

Explore more

Realize your ideas and new innovations with us at our Tisse Technology Center

Valmet Tissue Technology Center is a unique resource for cultivating and realization of ideas, innovations and verifying new technology or machine configurations. We help you find the best solutions for the future.

With access to Best Available Technology, Best Operational Practices and Best Acting People we provide a creative environment for developing and testing new products, improve product quality and machine performance.

The Tissue Technology Center give you access to one full sized, flexible pilot machines that can be configurated for conventional, textured and structured tissue processes, equipped and organized laboratory as well as our wide technology and process expertise.

Unable to travel? This should not be a reason to put your development on hold. Therefore we are offering the possibility to either visit us in Karlstad, Sweden or do the pilot trial remotely. Follow the activities in the trials through live streaming cameras broadcasted on a secured web page and take part of data without delay in common software tools.

Pilot trials onsite or remotely

Get in touch with us and we can set up a tailor made plan according to your specific needs.

Book today

Project execution services

By being involved in the whole project chain we are reducing the total project risk and taking care of obstacles that are not obvious from the beginning. With good teamwork and seamless integration between all project phases we enable successful projects and fast start-ups.

We are with you throughout the entire process and our work is always based on

- Engangement- from an organisation dedicated only for tissue, with focus on understanding the specific project needs

- Professionalism- by involving global, regional and local expertise and experience

- Commitment - by focusing on common success criteria and long term support

Questions and answers about tissue making solutions

Q: How to select the right tissue machine?

A: Valmet can offer a variety of tissue making solutions depending on the producer’s need. We have a wide portfolio from small to medium sized machine producing conventional or plain tissue grades and hybrid machines for plain and textured paper to the through air drying process machine for high quality, low fiber production.

Our experts can support you with your needs: Contact us!

Q: How can I improve my tissue paper?

A: At Valmet we have the Tissue Technology Center with the tissue pilot machine where you can develop and test new products, improve product quality and machine performance. We welcome you to contact us to find the best solutions for your future production.

Q: How to make tissue paper?

A: This video explains how tissue paper is made: Watch!

Q: What machine to select for plain or conventional tissue production?

A: Valmet’s IntelliTissue concept is in the front line of small and medium sized tissue machines with proven crescent former technology combined with low media consumption. The conventional Advantage DCT machine has become a trademark for production of plain or conventional tissue products with high quality.