Wet strength broke deflaking technologies and best practices

Webinar date: September 24th, 1:00 pm EDT, 45 minutes + Q&A

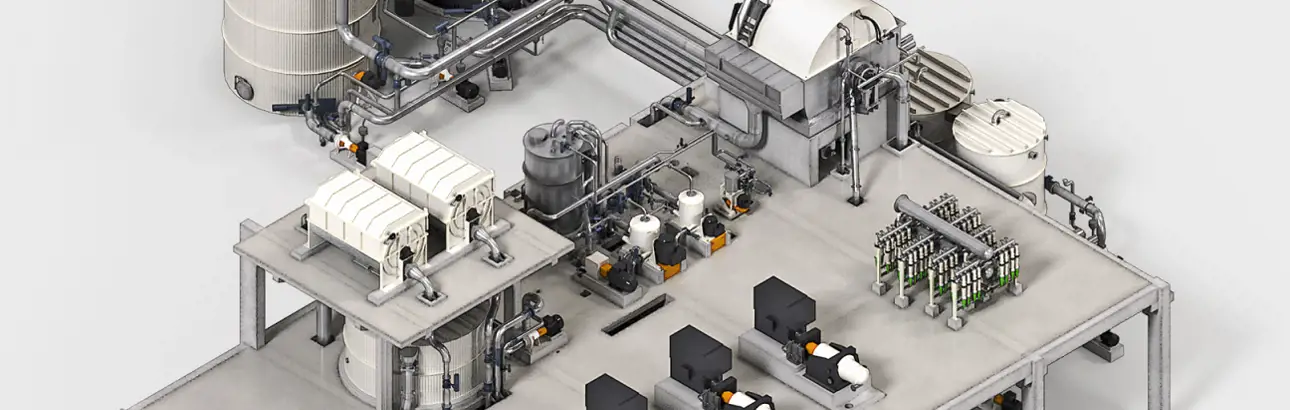

Pulping, deflaking, and screening broke with wet strength can be of critical importance to the broke handling process. Whether you're new to this area or looking to stay updated on the latest technologies, this webinar will offer practical insights into system configurations, operational best practices, and innovations that can enhance process control and efficiency.

Join us for a comprehensive look at wet strength broke systems, where we’ll explore equipment differences, recent technological developments, and proven ways to optimize your mill’s performance.

In this webinar, you will learn about:

- High and medium consistency pulping

- High consistency cleaning

- Deflaking and dispersion

- Broke screening

Can't make the live session? Don't worry, once you register we will send you a full high quality recording of the insider session that you can review at any time.

We also offer a Certificate of Attendance for this webinar, which serves as a great way to showcase your professional development—perfect for sharing internally and externally to display on platforms such as LinkedIn to highlight your commitment to continuous learning. To receive a Certificate, you must attend up until the Q&A portion.

[NOTE: The webinar will be in the English language. This webinar is only offered to pulp, paper, board and tissue producers, P&P industry consultants and university faculty and students. Use your company or university domain email address when registering. Products and services mentioned in this presentation may not be available in all regions.]

VALMET PRESENTER

|

Christopher Koterba With 15 years of experience working directly with Stock Prep Systems, Chris works to provide system design, contaminant analysis, research, and product development services to our customers in North America. |