Approach flow system

Energy saving solution

Lower life cycle costs

Exceptional runnability

Superior quality

Customized wet-end systems

Valmet´s approach flow concept is an integrated wet-end system that is always designed to the needs of the paper grade.

Board and paper makers can be assured of high stock quality and undisturbed runnability of the paper machine by using a customized approach system, featuring Valmet's advanced solutions.

Maximize productivity

Are you looking for maximized productivity, material efficiency, and runnability?

Contact usCleaning

Pulp and paper mills invest in hydrocyclone plants to improve efficiency and drive performance. Valmet’s hydrocyclone technology removes unwanted particles such as sand, glass, metal, inks, certain unwanted organics, plastics, wax, and Styrofoam down to 50 microns. The result is cleaner pulp, better quality products, and the protection of process equipment downstream.

Deaeration

Valmet offers both passive and active deaeration solutions to meet the varying needs of every papermaker, designed for different paper and board grades and forming concepts. Deaeration refers to the removal of air. The air in the stock can have negative effects on downstream equipment and the quality of the final product.

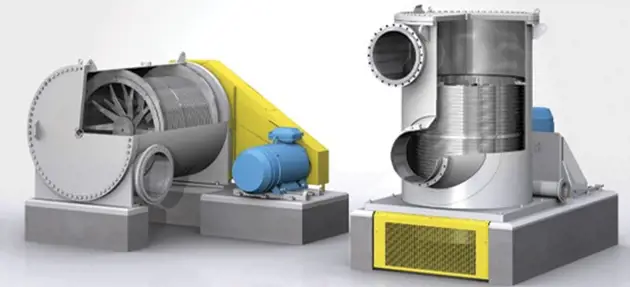

Machine Screening

Based on the design features of the outflow-type screen and the interaction of the patented rotor and foil designs, machine screens ensure the risk-free operation of paper, board, and tissue machines. Valmet’s machine screening features a robust outflow design, sturdy rotor and foil support, and durable screen baskets and are available in both vertical and horizontal designs.