Carbon capture is tackling global warming

Valmet’s automation solutions for carbon capture

Carbon capture plays a vital role in reducing CO₂ emissions, supporting power plants and various process industries in the fight against global warming and the transition towards cleaner energy. The captured CO₂ can either be permanently stored underground (Carbon Capture and Storage, CCS) or reused in the production of new materials or fuels (Carbon Capture and Utilization, CCU). For example, in utilization processes CO₂ stream can be converted into valuable products such as e-fuels through Power-to-X technologies. Valmet’s advanced automation solutions enhance plant efficiency, reliability, and sustainability, ensuring optimal performance in carbon capture operations.

Real-time control & monitoring

With its sophisticated control algorithms, Valmet DNAe enables real-time monitoring and adjustment of carbon capture and storage operations, ensuring optimal performance under all conditions.

Enhanced flexibility & scalability

Valmet DNAe adapts to varying operational demands and integrates seamlessly with existing and future systems, offering scalability for evolving needs.

Lower maintenance costs

Integrated condition monitoring and predictive maintenance reduce downtime, leading to lower maintenance expenses.

Learn to operate your new carbon capture process

Valmet Training Simulators are available for testing and training all process-based plants. Valmet has delivered hundreds of simulators for different process technologies.

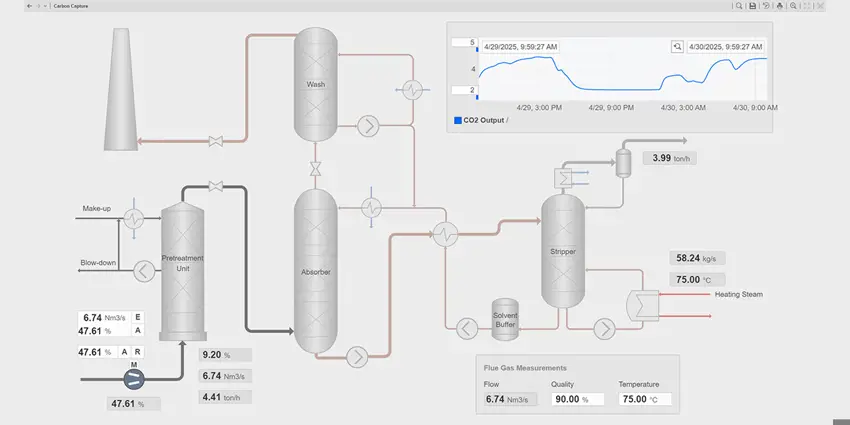

Carbon capture process where flue gas input, pretreatment, absorber, and stripper units are controlled to achieve the desired CO₂ output level. Valmet’s advanced automation solutions enhance plant efficiency, reliability, and sustainability, ensuring optimal performance in carbon capture operations.

Understanding the carbon capture process

Carbon capture is a proven technology designed to reduce CO₂ emissions from industrial processes and power generation.

Typically, the carbon capture process includes capture and transport, followed by either storage (CCS) or utilization (CCU).

- CO₂ capture: CO₂ is separated from flue gases produced by power plants and industrial activities such as cement, steel, bioethanol, oil refining, biogas production and hydrogen production. Various technologies, including post-combustion, pre-combustion, and oxyfuel combustion, enable efficient CO₂ capture at power plants.

- CO₂ transport: Once captured, the CO₂ is compressed and transported via pipelines, ships, or trucks to a designated storage site. Reliable transport infrastructure ensures safe and efficient delivery to permanent storage locations.

- CO₂ storage (CCS): The captured CO₂ is injected deep underground into geological formations such as depleted oil and gas fields or deep saline aquifers. These natural reservoirs safely store the CO₂, preventing it from entering the atmosphere.

- CO2 utilization (CCU): In the utilization process, CO2 is converted into useful products. Examples of the end products include synthetic fuels like e-methane or other e-fuels.

Valmet’s automation offering for carbon capture

Valmet provides comprehensive automation solutions for carbon capture, ensuring efficient operation and improved plant availability.

- Optimized automation - Our automation systems simplify startup with pre-configured sequences that assist operators and enhance system reliability. Energy-efficient operating modes enable precise control of the carbon capture process and allow fine-tuning for maximum performance. With Valmet DNAe, the carbon capture unit is integrated seamlessly into the existing processes as well as into new power-to-x processes, forming one unified system with smooth operations.

- Condition monitoring - The Valmet DNAe Automation System includes built-in condition monitoring for continuous tracking and proactive maintenance, minimizing downtime.

- Operator training - To ensure safe and efficient plant operation, operator training simulators are available, helping staff gain hands-on experience before working with live systems.

- Central control room & remote operations - Valmet’s central control room (CCR) and remote-control capabilities provide seamless plant monitoring and control. The system supports independent operation of remote plants with their own automation systems, with full compatibility for industry-standard connectivity protocols such as OPC UA, Profibus, and ModBUS TCP/IP.

- Advanced safety & security solutions - Valmet also offers integrated process functional safety systems (SRS) and fire & gas systems (FGS) within the Valmet DNAe automation platform.

- Cybersecure by design -Cybersecurity implements a defense-in-depth strategy, ensuring a highly reliable, efficient, and cybersecure automation system that protects critical industrial assets from cyber threats.

Complementary carbon capture solutions

Explore how Valmet DNAe can optimize your carbon capture process

Reach out to our experts today to learn how we can help enhance your plant’s efficiency, reliability, and sustainability.

Contact us