Supporting customer success in air separation through reliable valve solutions

The demand for oxygen in manufacturing continues to grow each year. This stretches from medical use to metal fabrication and beyond, further expressing the extreme importance of these air separation technologies.

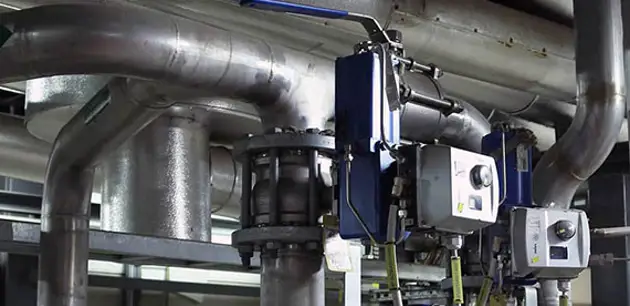

Separating oxygen from the air is not an easy task and often requires valves to meet specific standards in order to support the process. The importance of proper valve selection alone can have a substantial impact on how a unit operates. Although oxygen in the air we breathe is safe, once separated into pure oxygen, you face new potential hazards. Along with varying temperatures and differing elements flowing through the valves, it is crucial to ensure the right products are initially installed.

The process for separating oxygen consists of a few different parts, all being equally as important as the next. Starting with the dryer or Molsieve units, we remove excess water or impurities from the feed air, then travel to a cooler to lower the temperature of the feed, next moving onto the distillation column where the elements start to separate and are eventually moved to storage or distribution for use.

The long-term exposure to cold temperature as low as -184°C (-300°F) requires the valve assemblies’ internal components to be compatible with the process. This means that all soft goods and metallic parts of construction must be rated to the lowest temperature range. As oxygen can play a key component in combustion, certain standards for material also must be met in order to keep safety as a top priority. Valmet's cryogenic valves use specific materials that have been tested by either BAM or WHA, which are recognized global organizations that set material policies and requirements for materials in oxygen services to ensure compliance with our customers' process needs.

As a key valve supplier to ASUs (air separation units) for decades, we have and continue to offer solutions on a global scale. With thousands of installs, we work to guide our customers on the proper models of construction and needed materials to fulfill their process needs.

To learn more about how we can support your air separation challenges, check out our Air separation unit application report.

Flow control products and services for industrial gases