High-efficiency coating drying with minimum energy consumption

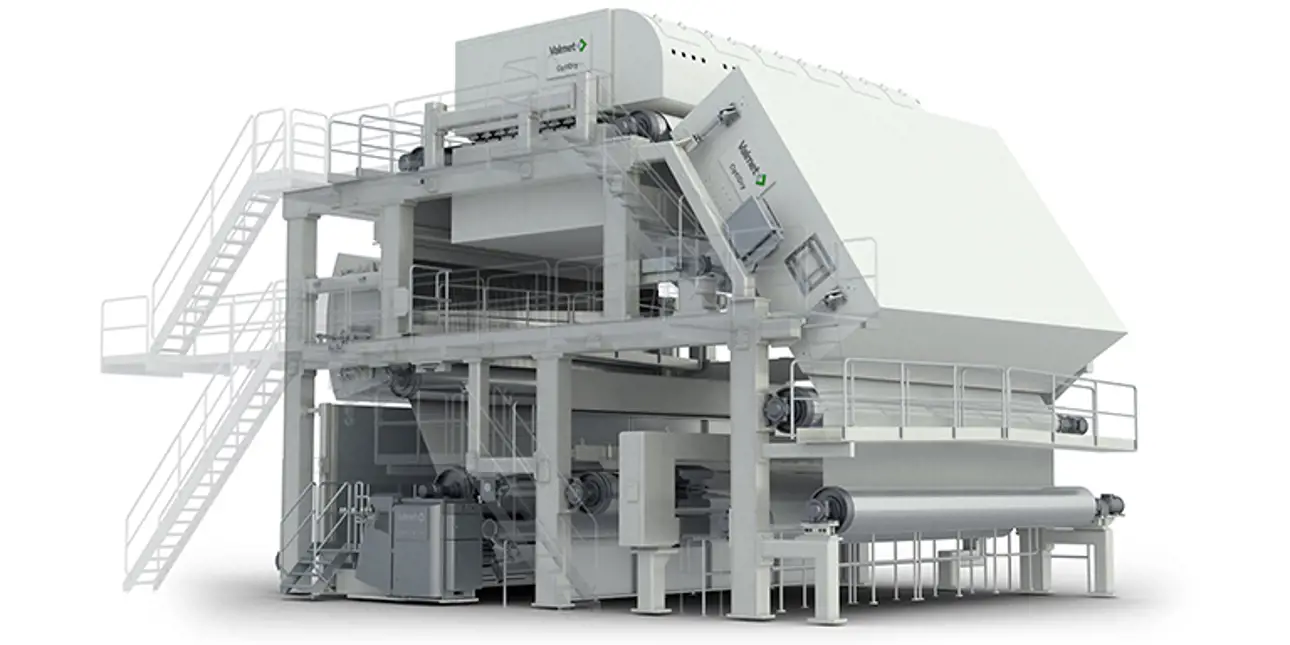

OptiDry Coat air dryers

OptiDry Coat air dryers are designed for high drying capacity. Aided by patented air dryer nozzles, the dryers achieve uniform evaporation with minimum energy consumption, high efficiency and excellent runnability. We can prove that you get the best paper quality and lowest energy consumption with Valmet air dryers.

Energy savings

Less maintenance costs

Better paper quality

High drying capacity

Because coating drying is an energy-intensive process, optimizing energy consumption is crucial. Air dryers can cut the energy costs of coating drying by up to half. Valmet air dryers offer energy efficiency rates between 70% and 80%, which is significantly higher than the 25% to 35% efficiency typically achieved with infrared (IR) dryers. This translates to energy savings of 50% or more when using air dryers instead of IR dryers. The OptiDry Coat air dryers are suitable for all coated paper and board grades and can be installed both on new machines and as part of rebuilds.

OptiDry Coat air dryers are available in different types to meet a wide range of coating drying requirements. For example:

- The OptiDry Coat high-intensity is an energy-efficient, high-performance air dryer that ensures fast and effective coating drying by optimally removing moisture.

- The OptiDry Coat air dryer is a versatile solution suitable for all coating drying applications, offering flexibility for various heating and layout configurations.

Using OptiDry air dryers provides several benefits:

- Outstanding energy efficiency

- High drying capacity

- Superior end product quality

- Excellent runnability

- Easy and low-cost maintenance

- Improved working environment

- Reduced fire hazard

- Reduced environmental impact

For positions currently equipped with IR dryers, the OptiDry Coat high intensity air dryer offers a highly effective alternative, with numerous successful references in paper and board machines. By adopting the OptiDry air drying family and PowerFloat nozzles, you start to significantly reduce your energy costs.

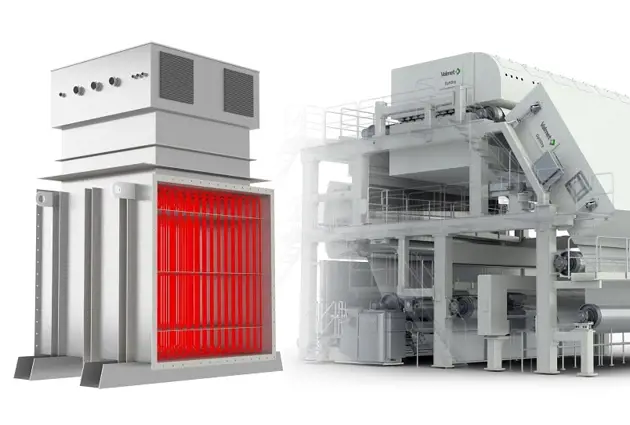

Upgrade your coating drying process with OptiDry Coat double-pass

To further enhance coating drying processes, OptiDry Coat double-pass takes the standard of high-intensity air drying followed by long air turn drying to a new level. OptiDry Coat double-pass combines three advanced air drying technologies in one compact solution, delivering superior coating quality while saving space and energy.

Why choose OptiDry Coat double-pass?

- Three dryers in one compact frame, saving space and reducing investment costs

- Contactless air drying with an ideal drying strategy for excellent coating and printing quality

- Best energy efficiency on the market with advanced Valmet Air Dryer Nozzles for optimal performance

- Modular and flexible design for all coating applications

- Compatible with multiple heating sources and supports fossil-free energy alternatives

OptiDry Coat double-pass coating air dryer

Three air drying stages for optimal results

The high-intensity air dryer section removes free water quickly to prevent absorption into the baseboard, ensuring a mottling-free surface with superior gloss and smoothness. The turning dryer section uses air to turn the web contactlessly and at a lower temperature, ensuring pigments and binders remain at their optimum temperature. The moisture control section stabilizes coat moisture and temperature with high air speed or heat, delivering perfect print quality without swelling or shrinking.

Sustainable and cost-efficient

OptiDry Coat double-pass is an energy-efficient, reliable and sustainable solution for coating drying. It offers the best energy efficiency on the market and features superior Valmet Air Dryer Nozzles for optimal performance. It supports fossil-free energy alternatives and works with all common heating sources, including electricity, steam and gas. The design requires less maintenance and improves the working environment by reducing heat and humidity in the machine hall, thanks to its no free draw feature.

Want to talk to our coating drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsReplacing gas with electricity

Many paper producers are looking for ways to eliminate fossil fuels from their production processes. How can this be done in coating drying?

A highly effective and future-ready way to achieve fossil-free coating drying is to use electric heating. Switching from a gas burner to electric heating can also help save energy. When electric heating replaces a gas burner in an air dryer and the process is optimized, energy savings are typically around 10 percent.

Do you want to know more about the electrification of air dryers?

We have answered frequently asked questions about replacing gas with electricity and infra-red dryers with air dryers.

Check the Q&AExplore our latest board and paper press releases

- Jan 29, 2026Valmet launches new Bioneer press roll covers with reduced climate impact

- Dec 19, 2025Muoto products produced with Valmet 3D Fiber technology piloted at Valmet’s Jyväskylä location

- Dec 8, 2025Valmet has completed change negotiations for temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Nov 26, 2025Valmet supports Wuzhou Special Paper’s transition to recycled board grades with a complete paper machine conversion rebuild

- Nov 5, 2025Valmet to start change negotiations regarding temporary layoffs in the Packaging and Paper business area and Global Supply unit in Finland

- Sep 16, 2025Valmet strengthens customer value by delivering a high-end sack and kraft paper machine for Guangxi Jianhui Paper in China

- Aug 21, 2025Valmet to supply two papermaking lines to a customer in China

- Aug 18, 2025Successful start-up of Sappi North America’s rebuilt board machine PM 2

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency

- Aug 7, 2025Successful start-up at Liansheng Pulp & Paper’s coated board making line PM 2