Automation for Tissue

Field-proven automation solutions to meet your production goals

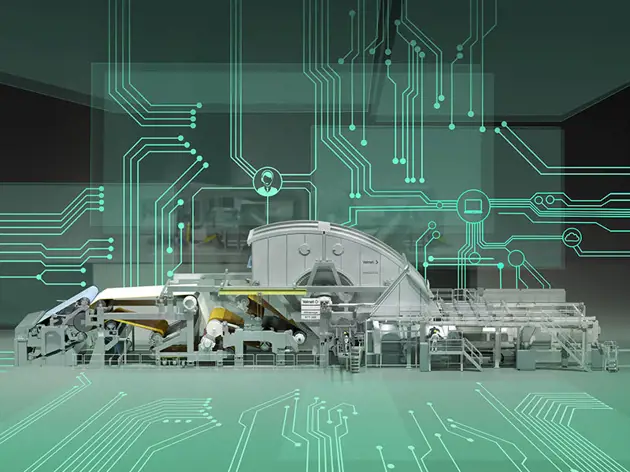

Did you know Valmet is the only OEM automation and tissue process equipment supplier. Tissue makers around the world choose Valmet as their automation partner. With a strong focus on long-term, continuous improvement, customers get maximum value over the lifetime of their investments. Our complete offering maximizes your production goals, from sustainability and safety to process reliability and asset efficiency.

Systems and Products

Towards sustainable, autonomous operations

Process instability can weaken tissue machine runnability and increase costs. Opportunities are often missed as operators focus on individual machines or raw materials. Siloed adjustments can introduce even more variability, leading to off-target production.

Valmet’s automation system measures and controls variability across the entire production line. Teams work together from the same data towards plant-wide goals, improving asset reliability and performance to drive optimization.

Global pressures are driving tissue production towards entirely new levels of efficiency and predictability. Digitalization can lead to complexity, creating both challenges and opportunities. Valmet’s automation solutions remove technical barriers, unifying data so it can be securely and easily leveraged to reach target quality at much reduced costs.

On this image

-

1 Pulp to Paper Optimizer

-

2 Quality control system (QCS)

-

3 Distributed control systems (DCS)

-

4 Valmet Performance Center

-

5 Fiber Furnish Analyzer

-

6 Consistency measurements

-

7 Wet End Analyzer

-

8 Valmet IQ Dilution Profiler

-

9 IQ Web Monitoring System

-

10 Valmet IQ Steam Profiler

-

11 IQ Web Inspection System

-

12 High-speed scanners for precise quality control

Pulp to Paper Optimizer

Valmet Pulp to Paper Optimizer is designed to control the properties of the paper by automatically stabilizing and optimizing the process variables to the most cost-effective level while maintaining the agreed quality.

Quality control system (QCS)

The Valmet IQ Quality Control System (QCS) is a highly customizable quality management solution that helps you increase process performance while meeting your quality goals.

Distributed control systems (DCS)

Valmet DNA and Valmet DNAe are safe, future-proof distributed control systems built on your industry's leading process know-how. They empower your people to perform at their best, utilizing a unified user interface and sharing advanced data analytics from Valmet DNAe. With lifetime systems compatibility, step-by-step upgrades, and seamless migration from other DCS and PLC systems, you can unlock the full potential of your 24/7 operations for decades to come.

Valmet Performance Center

Easy access to Valmet’s experts through remote connections. Get support in technical or process-related challenges whenever needed.

Fiber Furnish Analyzer

Valmet Fiber Furnish Analyzer (Valmet MAP Q) provides paper, board, and tissue makers with fast and precise online updates of key fiber and papermaking furnish properties.

Consistency measurements

Valmet's development of consistency measurements is based on over 40 years of experience

Wet End Analyzer

The Valmet Wet End Analyzer (Valmet WEM) is a modular online measurement solution that provides tissue, board and papermakers with all the key variables for effective wet end management.

Valmet IQ Dilution Profiler

Valmet IQ Dilution Profiler has been specially designed for achieving the best possible weight profile that a headbox can produce.

IQ Web Monitoring System

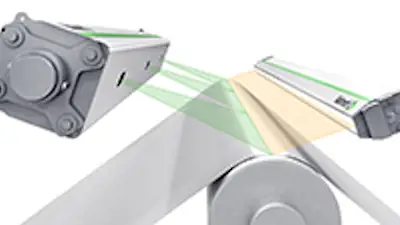

The newly enhanced Valmet IQ Web Monitoring System (Valmet IQ WMS) delivers unmatched performance for today’s demanding production environments. Designed for advanced process analysis, it enables operators to quickly identify and trace defect origins as they occur. With industry-leading illumination, sharper visuals and the most compact design available, it helps maximize product quality and efficiency across the pulp, paper, tissue, and paper & board converting industries.

Valmet IQ Steam Profiler

Valmet IQ Steam Profiler is the highest efficiency steam profiler family to increase production capacity, decrease energy consumption and improve moisture profile.

IQ Web Inspection System

Unique lighting technology enables the detection of print-critical defects that have not been visible before. More sensitive and reliable defect analysis can be achieved with multi-geometry.

High-speed scanners for precise quality control

At the heart of the Valmet IQ quality control systems are Valmet IQ Scanners. Featuring unique adaptive scanning capabilities, they can be used with a wide of range high-quality online measurements for precise quality control.

The right tools for everyone

Giving people the tools to get the best performance out of assets output is central to Valmet’s tissue offerings. Valmet DNAe is the most flexible, user-friendly distributed control system (DCS) on the market.

The DCS is the core of automated operations, including critical process and drive controls of the tissue machine line. It provides a consistent, web-based user experience for monitoring process controls, optimizing targets, assessing equipment condition, generating detailed reports and more. Essential information is accessible from any device regardless of physical location.

Information is easily shared between shifts and among teams, ensuring complete situational awareness for everyone. Analytics and simulators, part of Valmet DNAe, further help users to get the most out of their data. Overall performance improves as teams can focus on the most impactful actions and preempt potential issues.

Complete automation for tissue makers

Valmet’s automation system is highly scalable and suites operations both big and small. You can start with the most critical components and expand the automation scope later as needed. Valmet provides a wide range of sensors, measurements, analyzers, profilers, monitoring & inspection tools, and scanners that are integrated into the DCS.

Valmet IQ Quality Control System (QCS), for example, automatically adjusts stock feed, drying, machine speed, crepe ratio, profiles, and grade changes. Thanks to the online scanner measurement specially designed for tissue, you can measure the most critical quality properties of the tissue, as well as closely monitor the success of the creping process. Utilizing these measurements in a condition monitoring system, you can also identify factors affecting Yankee performance in advance, such as chattering issues.

With our advanced process controls (APCs) and digital jumbo reel, you can achieve even broader optimization of the tissue making process for precise quality control and enhanced overall equipment effectiveness (OEE). These solutions include automating refining, pulp mixing, chemical dosing and data sharing between tissue machine and converting lines.

On-target quality with the lowest cost

Valmet helps you identify process areas where savings could be most easily achieved for a given tissue grade. The automation system stabilizes variations, ensuring steady and predictable quality. You get real-time data and insights to make sure processes use the minimum raw materials to produce exactly the desired quality.

Consider the challenge of strength quality variation in a single towel grade. Valmet’s solutions help producers control the properties of the raw softwood and hardwood mix, refining, and chemicals. With data from the entire production line, operators can reduce the consumption of long fiber, as well as use less wet and dry strength chemicals.

Ensure high overall equipment effectiveness (OEE)

An automation system is much more than just a tool for process control and optimization. It also enables extensive condition monitoring of your tissue machine and converting line assets, an essential ingredient in avoiding unplanned shutdowns.

Valmet works with the tissue production line as a whole. Stock preparation and tissue machine stability are crucial to manage so that the machine can operate efficiently and produce quality with minimal variation. This also enables smooth running of tissue converting lines and maximizes OEE.

Our automation system significantly improves the overall effectiveness of existing equipment, while even larger gains can be made with targeted investments in new process technology.

Continuously improve with a committed partner

Decades of experience, along with a proven track record of successful tissue projects, put Valmet in a unique position to help tissue makers modernize and optimize operations to maximize performance. Our worldwide team of experts is always available to ensure you can optimize your processes and reach the most optimum equipment efficiency.

From a greenfield startup to a brownfield upgrade, Valmet is there to help you at every step in your journey towards fully optimized, autonomous operations. We provide comprehensive services close to your operations, as well as through an extensive remote support network.

You can be certain that you are making the right, data-driven choices through predictive diagnostics and real-time information from system applications and tissue production equipment. Our expert advice and automation solutions deliver tangible benefits now and over the long term.

Are you interested in specifications, prices and expert services?

Our experts are here for you and ready to discuss your challenges. Just answer a few questions and we will contact you shortly.

Contact usNews

- Feb 12, 2026Valmet increases Yusen Groups’s production capacity for high-quality tissue with three additional IntelliTissue machines

- Jan 14, 2026Valmet will support Faderco Group doubling tissue production capacity with a third Advantage DCT tissue line

- Dec 18, 2025Valmet’s Advantage ViscoNip press technology to enhance performance and product quality at five Lee & Man tissue machines in China

- Nov 18, 2025Valmet tissue converting technology: The Perini Proxima S8, efficiency and flexibility to boost productivity.

- Oct 29, 2025Valmet enhances Sofidel America’s ultra-premium tissue production with new Advantage ThruAir line

- Sep 17, 2025From Tissue machine to converting line: mastering dust handling with Valmet DustControl

- Aug 25, 2025Valmet to deliver an IntelliTissue 1600 machine to PT Suparma Tbk in Indonesia

- Aug 13, 2025Valmet launches next-generation Valmet Conical Refiner Conflo L model, designed for higher capacity and efficiency