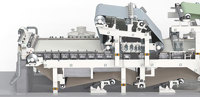

Fiber flash dryer

The Valmet Fiber Flash Dryer is a money saving alternative when you invest in a pulp drying line. A flash drying system for both mechanical and chemical pulp entails considerably lower investment than conventional sheet drying plants.

Pulp