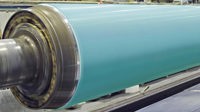

Sizer roll covers

The film sizing and film coating process have a direct impact on paper and board quality, both on paper strength as well as on paper appearance. Moreover, as on-line processes they are critical for the paper machine line efficiency. This puts high demands on the sizer roll covers.

Services