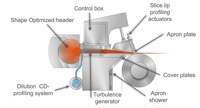

OptiFlo headbox: where quality is made

Headbox technology plays a critical role in defining end-product quality and properties. We asked three of our experts what enables OptiFlo headboxes to deliver the best possible results for board and paper machines.

Insights ● Article