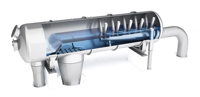

Bleach Plant Scrubber

Chlorine dioxide and ozone vapors from bleaching chemicals are harmful to the environment. The chlorine containing compounds in the bleach plant's exhaust gases are absorbed and acidic compounds are neutralized in a bleach plant scrubber.

Pulp