Things to consider in valve selection for catalytic cracking

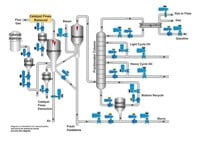

Reliable and accurate control, on-off and ESD-valve performance is important for total process efficiency, productivity and safety. Here’s presented some of the key-applications and things to consider in selecting valves for a typical FCCU.

Insights ● Blog post